Central system based on wireless torque detection

A technology of a mid-mounted system and a wireless transmitter, which is applied in the directions of rider driving, transportation and packaging, and vehicle components, can solve the problems of inability to achieve power assistance, complex mechanical structure, and undetectable, and achieve a large torque detection range, The effect of optimizing the delivery method and reducing the load on the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

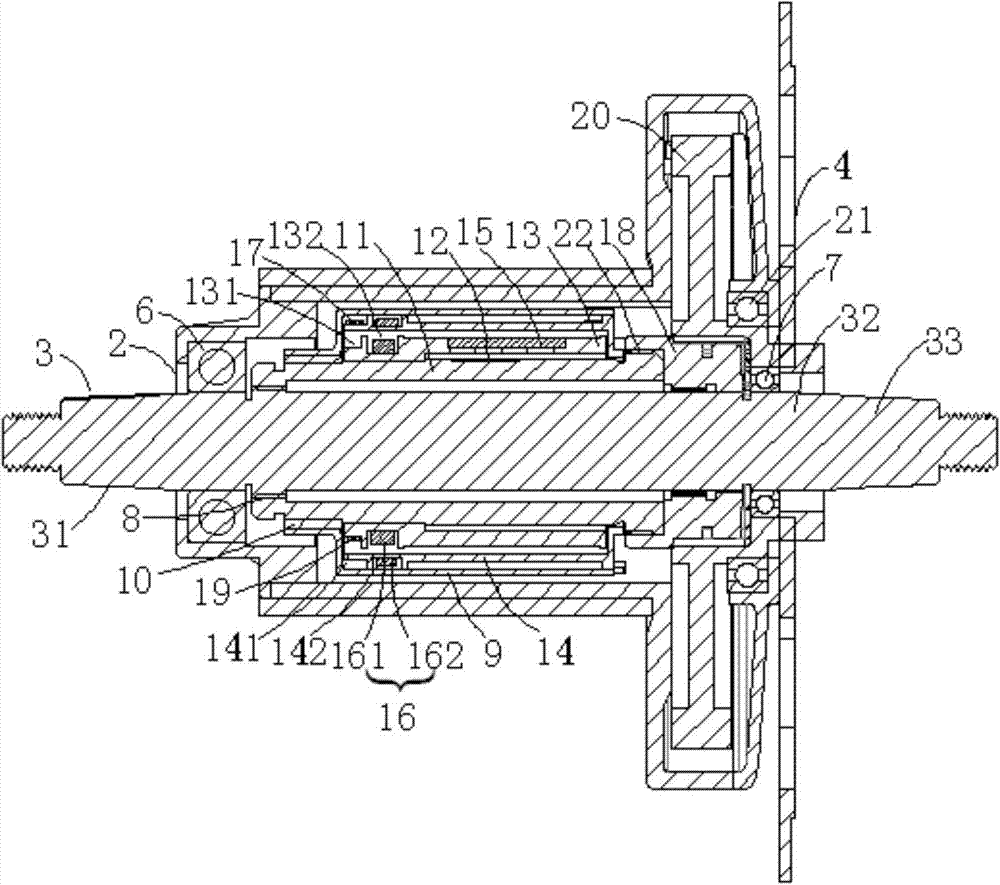

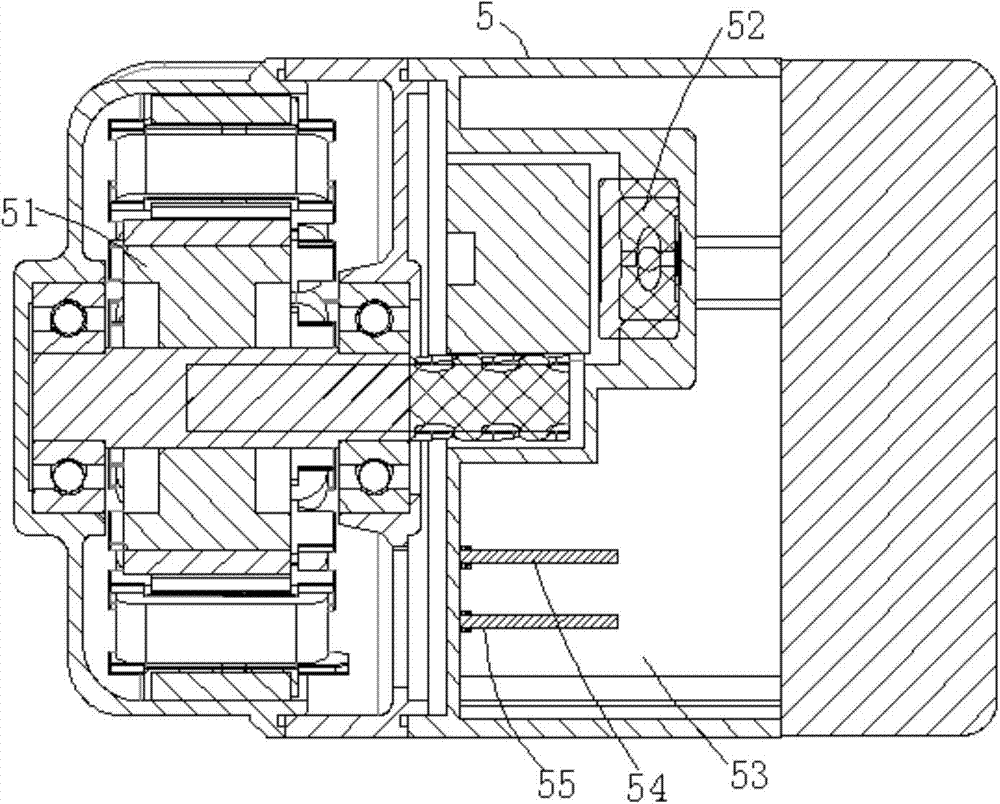

[0034] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

[0035] The orientation description in the present invention is according to Figure 1~6 The orientation in is described in detail, that is, Figure 1~6 The up, down, left, and right directions in are the up, down, left, and right directions described in the present invention.

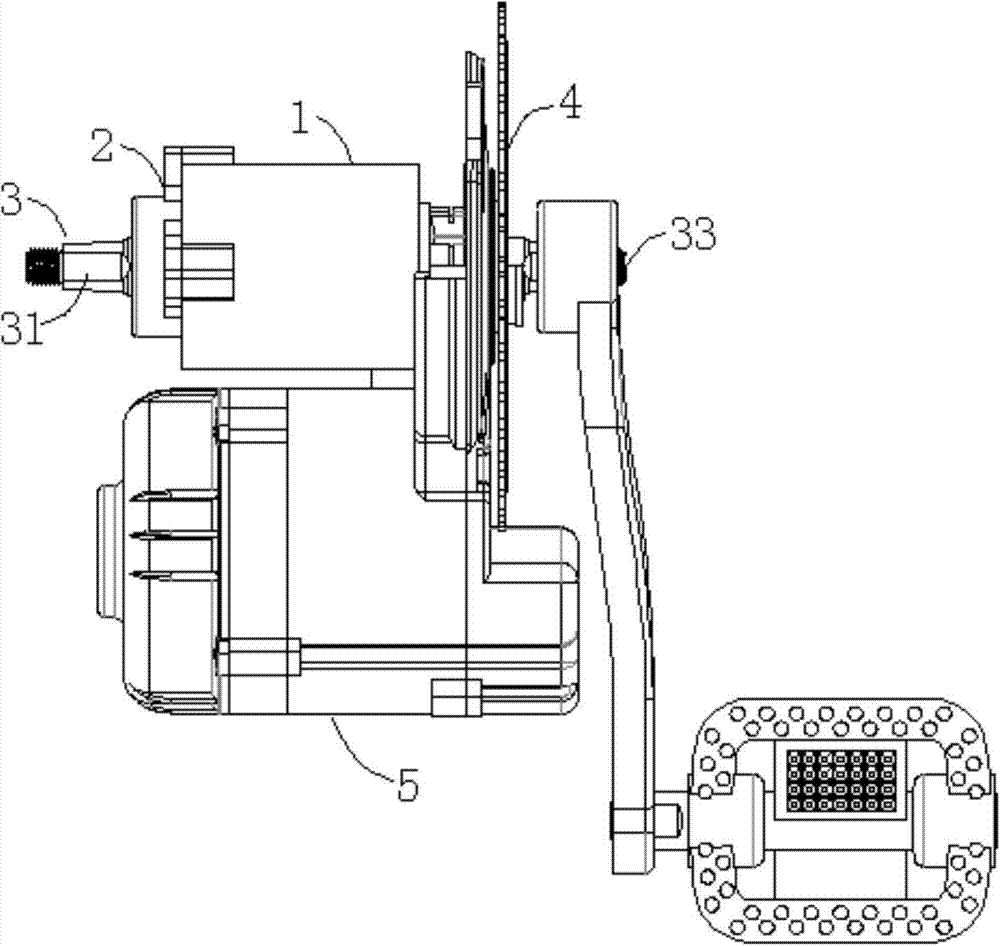

[0036] A mid-mounted system based on wireless torque detection disclosed by the present invention is mainly used on power-assisted bicycles, and provides the kinetic energy required for the bicycle to travel through the driving mode of electric power assisting manpower. It can realize zero start, and the riding effect is excellent; it is also suitable for all road conditions, and can obtain better boosting effect when riding at low speed or high speed. It has the advantages of convenient installation and maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com