Method for preparing amorphous calcium carbonate nanospheres

A technology of amorphous calcium carbonate and nanospheres, applied in the directions of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve problems such as poor stability of amorphous calcium carbonate, and achieve good application prospects, convenient operation, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] At room temperature, 0.925 g of CaCl 2 Dissolved in 250 ml of deionized water to form A solution, 1.060 g of Na 2 CO 3 Dissolve in 100 ml of deionized water to form liquid B; take 0.055 g of adenosine triphosphate disodium salt hydrate and dissolve it in 30 ml of solution A and adjust its pH to 9 with 1 mol / L sodium hydroxide solution, then add 10 ml of B dropwise During this process, magnetic stirring was used to keep the pH value at about 9; the dropwise addition was completed, stirred at room temperature for 1 hour, and then centrifuged, and the separated solid was washed 3 times with deionized water, and then washed with absolute ethanol Wash once, and finally dry in air at 60°C.

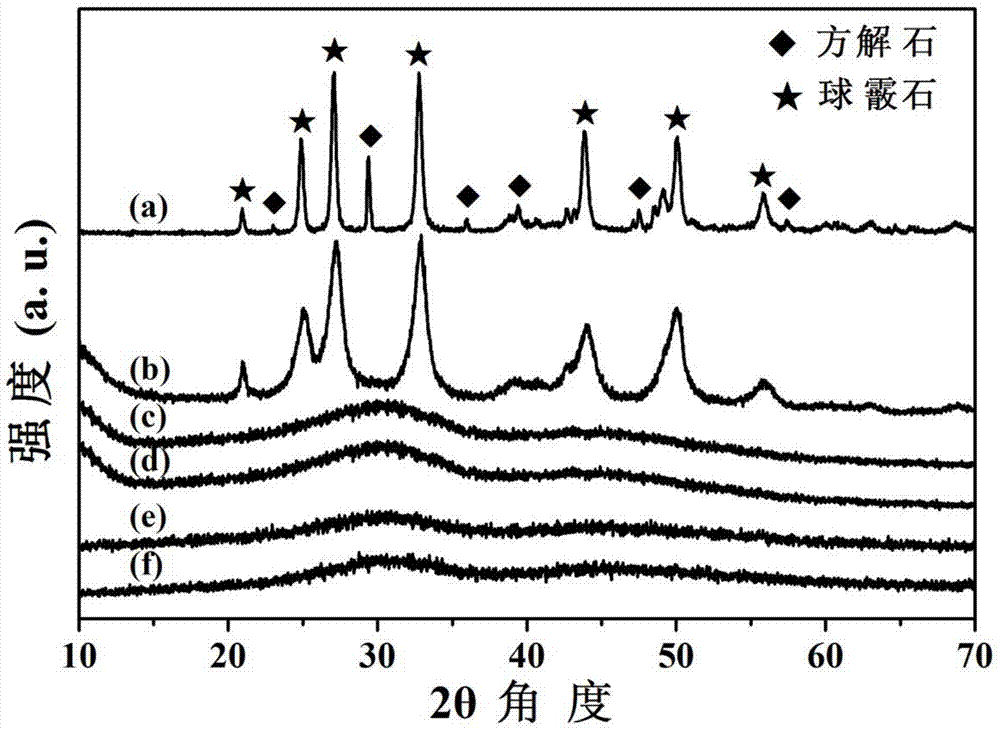

[0045] The X-ray (XRD) diffraction pattern of the obtained sample is as follows figure 1 Shown in the curve c in: the obtained sample is an amorphous phase.

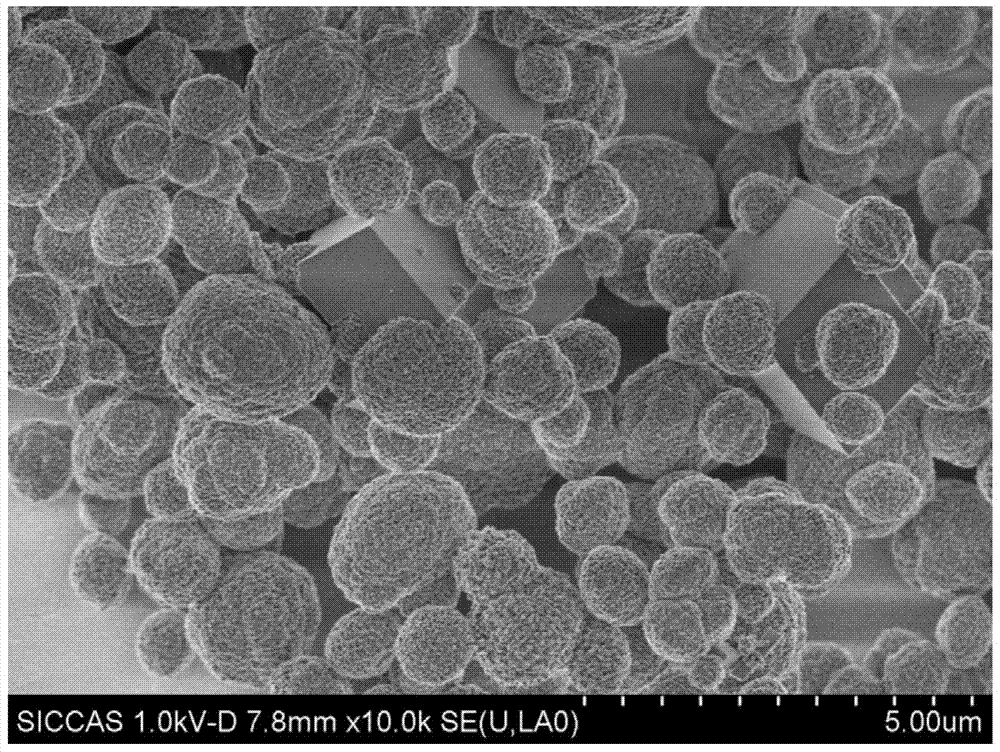

[0046] The SEM photographs of the obtained samples are as Figure 4 Shown: the obtained sample is a calcium carbonate nanosph...

Embodiment 2

[0048] At room temperature, 0.925 g of CaCl 2 Dissolved in 250 ml of deionized water to form A solution, 1.060 g of Na 2 CO 3Dissolve in 100 ml of deionized water to form liquid B; dissolve 0.088 g of adenosine triphosphate disodium salt hydrate in 30 ml of solution A and adjust the pH to 9 with 1 mol / L sodium hydroxide, then add 10 ml of liquid B dropwise In this process, magnetic stirring is used and the pH value is kept at about 9; the dropwise addition is completed, stirred at room temperature for 1 hour, and then centrifuged, and the separated solid is washed 3 times with deionized water, and then washed with absolute ethanol 1 time, and finally dry in air at 60°C.

[0049] The X-ray (XRD) diffraction pattern of the obtained sample is as follows figure 1 Shown in the curve d in: the obtained sample is an amorphous phase.

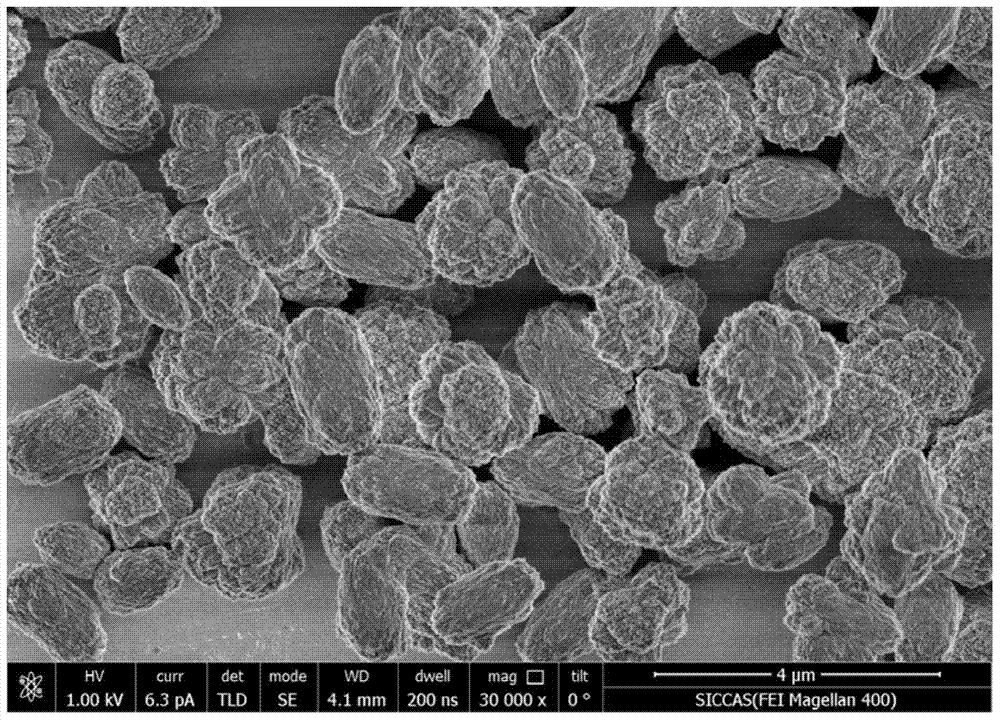

[0050] The SEM photographs of the obtained samples are as Figure 5 Shown: the obtained sample is a calcium carbonate nanosphere with a diameter o...

Embodiment 3

[0052] At room temperature, 0.925 g of CaCl 2 Dissolved in 250 ml of deionized water to form A solution, 1.060 g of Na 2 CO 3 Dissolve in 100 ml of deionized water to form liquid B; take 0.110 g of adenosine triphosphate disodium salt hydrate and dissolve it in 30 ml of solution A and adjust its pH to 9 with 1 mol / L sodium hydroxide, then add 10 ml of liquid B dropwise In this process, magnetic stirring is used and the pH value is kept at about 9; the dropwise addition is completed, stirred at room temperature for 1 hour, and then centrifuged, and the separated solid is washed 3 times with deionized water, and then washed with absolute ethanol 1 time, and finally dry in air at 60°C.

[0053] The X-ray (XRD) diffraction pattern of the obtained sample is as follows figure 1 Shown in the curve e in: the obtained sample is an amorphous phase.

[0054] The SEM photographs of the obtained samples are as Image 6 Shown: the obtained sample is a calcium carbonate nanosphere with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com