A preparation method of ultra-high deacetylation degree chitosan using Antarctic krill as raw material

An Antarctic krill and deacetylation technology, which is applied in the field of polymer polysaccharide preparation, can solve the problems of difficulty in meeting the demand for high-quality chitosan, industrial application and human health impact, and poor repeatability of chitosan products. The effect of low cost, less impurities and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of chitosan with ultra-high degree of deacetylation using Antarctic krill as raw material, comprising the following steps:

[0035] (1) Demineralization: take dry Antarctic krill shells, soak in acid solution, filter, collect shrimp shells, wash with water until neutral, and obtain demineralized shrimp shells;

[0036] (2) Removal of protein and lipids: The demineralized shrimp shells obtained in step (1) are placed in lye and heated, and then filtered to collect the shrimp shells, washed with water until neutral, to obtain the demineralized shrimp shells obtained in step (1). shrimp shell;

[0037] (3) Demineralization: soaking the shrimp shells obtained in step (2) after removing proteins and lipids in an acid solution, filtering, collecting the shrimp shells, washing with water until neutral, to obtain demineralized shrimp shells;

[0038] (4) Removal of protein and lipids: the demineralized shrimp shells obtained in step ...

Embodiment 1

[0054] A preparation method of ultra-high degree of deacetylation chitosan with Antarctic krill as raw material, comprising the following steps:

[0055] (1) Demineralization: Take 10 g of dry Antarctic krill shells, soak them in 100 mL of 2mol / L dilute hydrochloric acid for 1 hour at room temperature, filter, collect shrimp shells, and wash with water until neutral to obtain demineralized shrimp shells;

[0056] (2) Removal of protein and lipids: Take the demineralized shrimp shells obtained in step (1), place them in 150 mL of 1 mol / L sodium hydroxide solution, heat and boil for 1 hour, then filter, collect the shrimp shells, wash with water until neutral, and obtain Shrimp shell after protein and lipid removal;

[0057] (3) Demineralization: soak the shrimp shells obtained in step (2) after removing proteins and lipids in 100 mL of 2 mol / L dilute hydrochloric acid for 1 hour at room temperature, then filter, collect the shrimp shells, and wash with water until neutral to obta...

Embodiment 1 comparative example 1 comparative example 2

[0065] Viscosity / cps505±8.66325±7.2254±0.96

[0066] The viscosity of the chitosan prepared in this example is about 505cps, and the viscosity of Comparative Example 1 and Comparative Example 2 are about 325cps and 54cps respectively, indicating that the chitosan prepared by the present invention has a high relative molecular mass.

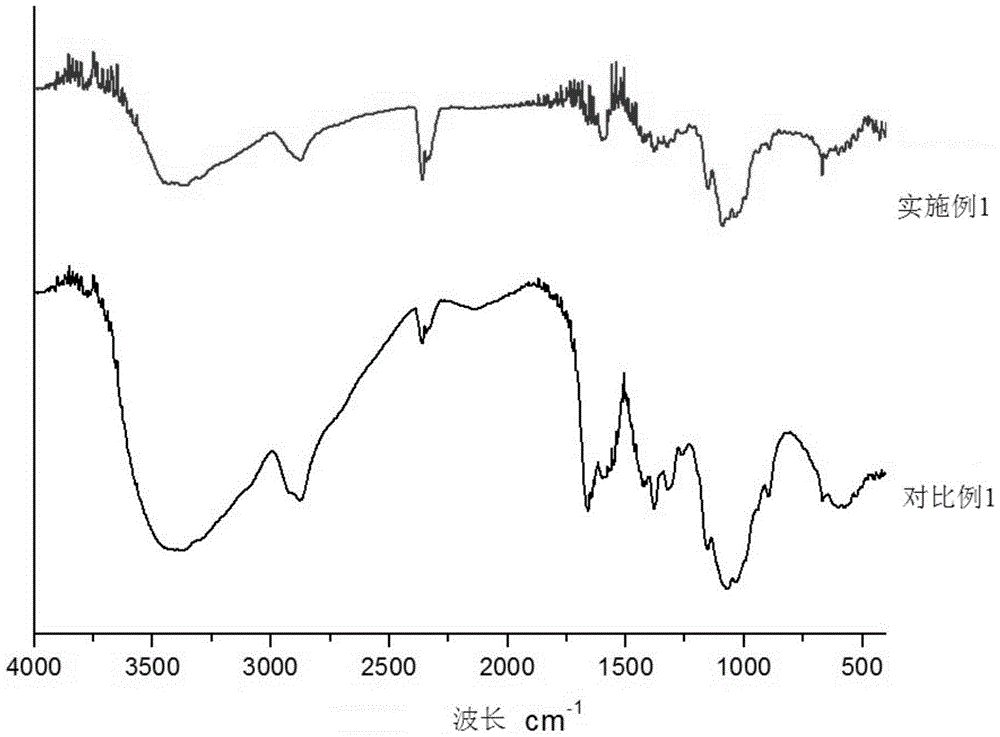

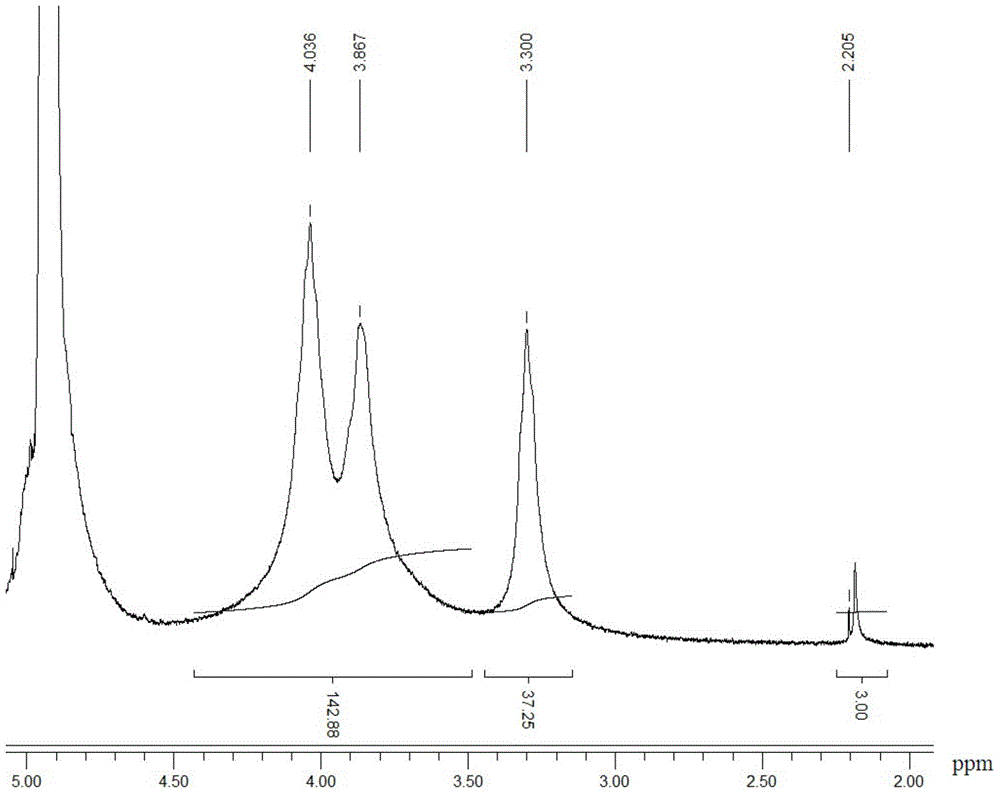

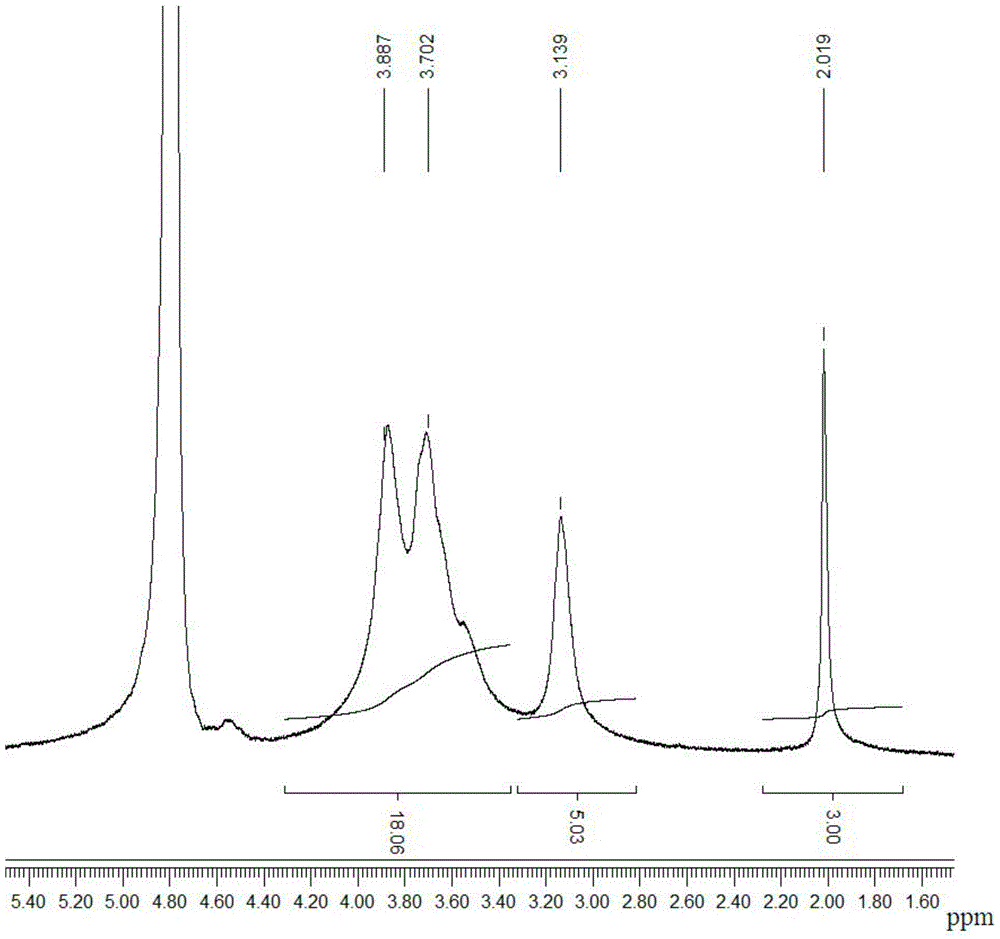

[0067] The chitosan prepared in this example and the chitosan of Comparative Example 1 were subjected to Fourier transform infrared test, and the test results refer to figure 1 ,from figure 1 It can be seen that Example 1 is at 3400cm -1 The stretching vibration peak of H-O appears at 2960cm -1 ~2840cm -1 C-H stretching vibration peaks of methyl and methine appear at 1655cm -1 C=O stretching vibration peak appears at 1604cm -1 N-H bending vibration peak appears at 1379cm -1 C-H bends and CH 3 Symmetrical deformation vibration peak at 1323cm -1 C-N stretching vibration peak appears at 1260cm -1 ~1000cm -1 The C-O stretching vibration peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com