Continuous polymerization method

A polymerization method and a technology of polymerization units, which are applied in the field of continuous polymerization, can solve problems such as catalyst performance differences, polymer performance fluctuations, and polymerization product performance fluctuations, and achieve the effects of small performance fluctuations, stable performance, and automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the continuous polymerization method provided by the present invention.

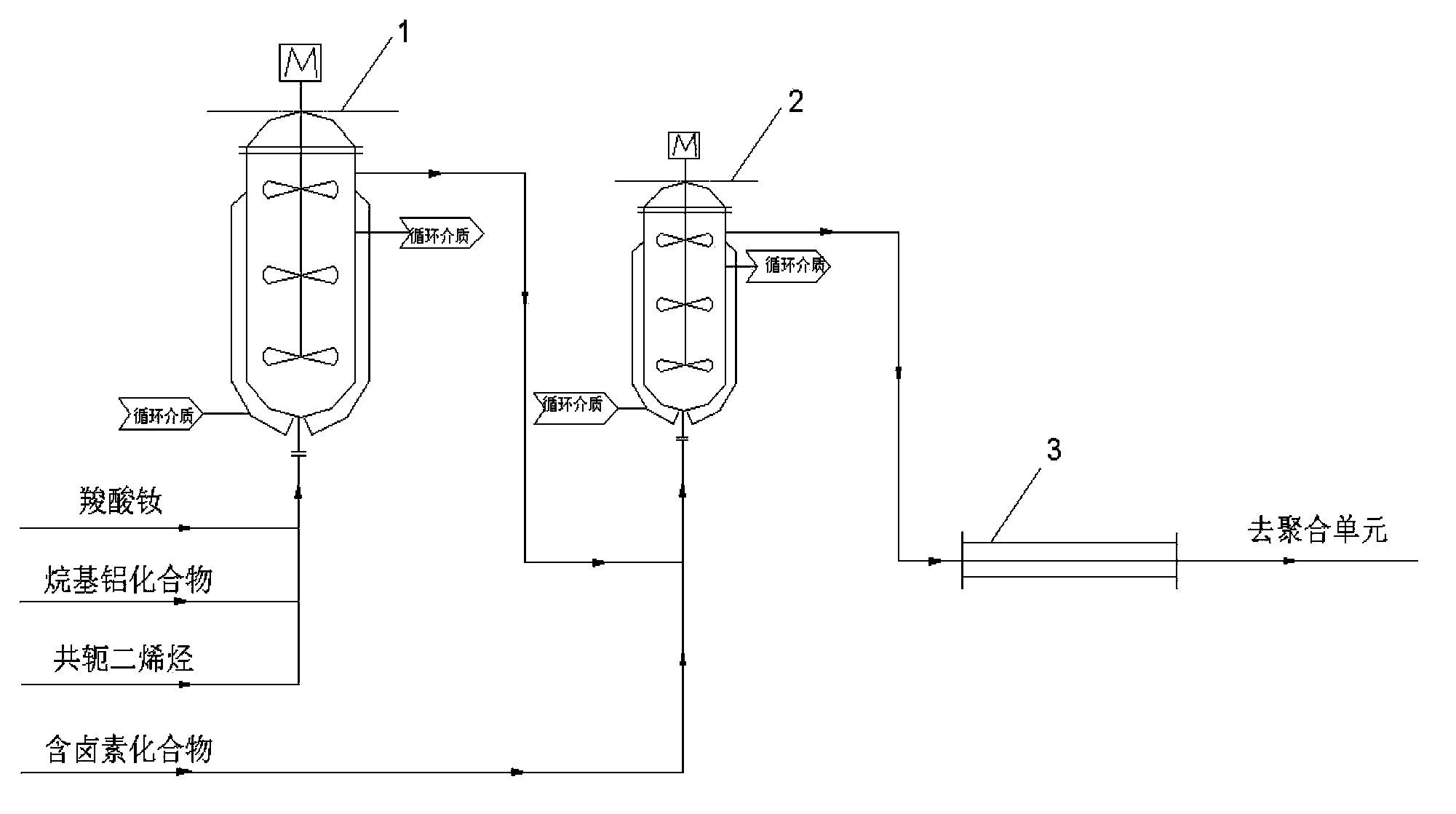

[0044] according to figure 1 The flow chart shown is aggregated:

[0045] (1) Preparation of rare earth catalyst:

[0046] Under the protection of nitrogen, a metering pump is used to continuously add neodymium neodecanoate / hexane solution with a concentration of 0.01mol / L and diisobutylaluminum monohydrogen / hydrogen with a concentration of 0.1mol / L to the first tank reactor 1. For the hexane solution and the butadiene / hexane solution with a concentration of 0.05mol / L, the control flow rates are 244mL / h, 366mL / h and 500mL / h respectively, the operating temperature is 40°C, and the residence time is 45min. After the first tank reactor 1 is filled with materials, use a metering pump to continuously add diethylaluminum chloride / hexane solution with a concentration of 0.02mol / L to the second tank reactor 2 at a flow rate of 280mL / h , the operating temperature is 30...

Embodiment 2

[0050] This example is used to illustrate the continuous polymerization method provided by the present invention.

[0051] according to figure 1 The flow chart shown is aggregated:

[0052] (1) Preparation of rare earth catalyst:

[0053] Under the protection of nitrogen, a metering pump is used to continuously add neodymium neodecanoate / hexane solution with a concentration of 0.01mol / L and diisobutylaluminum monohydrogen / hydrogen with a concentration of 0.1mol / L to the first tank reactor 1. For the hexane solution and the butadiene / hexane solution with a concentration of 0.05mol / L, the control flows are 366mL / h, 900mL / h and 2050mL / h respectively, the operating temperature is 60°C, and the residence time is 20min. After the first tank reactor 1 is filled with materials, use a metering pump to continuously add diethylaluminum chloride / hexane solution with a concentration of 0.02mol / L to the second tank reactor 2 at a flow rate of 680mL / h , the operating temperature is 10°C, an...

Embodiment 3

[0057] This example is used to illustrate the continuous polymerization method provided by the present invention.

[0058] according to figure 1 The flow chart shown is aggregated:

[0059] (1) Preparation of rare earth catalyst:

[0060] Under the protection of nitrogen, a metering pump is used to continuously add neodymium neodecanoate / hexane solution with a concentration of 0.01mol / L and diisobutylaluminum monohydrogen / hydrogen with a concentration of 0.1mol / L to the first tank reactor 1. For the hexane solution and the butadiene / hexane solution with a concentration of 0.05mol / L, the control flow rates are 270mL / h, 400mL / h and 850mL / h respectively, the operating temperature is 30°C, and the residence time is 56min. After the first tank reactor 1 is filled with materials, use a metering pump to continuously add diethylaluminum chloride / hexane solution with a concentration of 0.02mol / L to the second tank reactor 2 at a flow rate of 400mL / h , the operating temperature is 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com