Environment-friendly efficient corrosion inhibitor as well as preparation method and application of environment-friendly efficient corrosion inhibitor

A corrosion inhibitor and high-efficiency technology, applied in the field of environmental protection and high-efficiency corrosion inhibitor and its preparation, can solve the problems of high cost, carcinogenicity, poor water solubility, etc., and achieve the effect of low cost and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

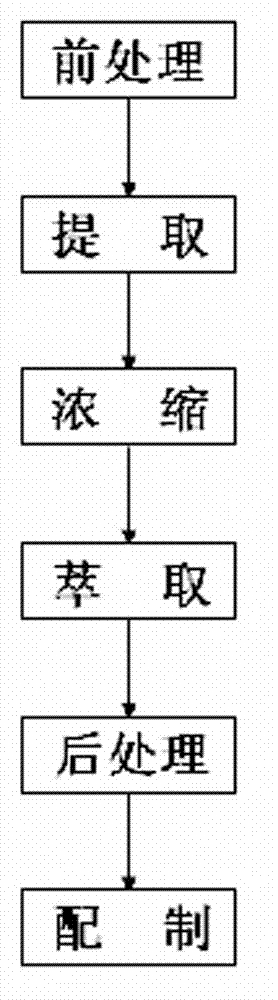

[0018] The preparation method of the environment-friendly high-efficiency corrosion inhibitor of the present invention includes raw material preparation and preparation steps, specifically including:

[0019] A, raw material preparation: prepare bamboo leaf extract for subsequent use, prepare pickling solution, allylthiourea, Tween, quaternary ammonium salt, sodium iodide for subsequent use;

[0020] B. Preparation: Add bamboo leaf extract, allylthiourea, Tween, quaternary ammonium salt, and sodium iodide into the pickling solution according to the ratio of raw materials, stir and mix evenly to obtain the target product.

[0021] Described preparation bamboo leaf extract comprises the following steps:

[0022] A. Pre-treatment: After the bamboo leaves are collected, remove the surface impurities, rinse with water to remove the dust on the leaf surface, drain the surface water, air-dry them, put them in a blast oven, dry them at a constant temperature of 50-70°C for 36-60 hours...

Embodiment 1

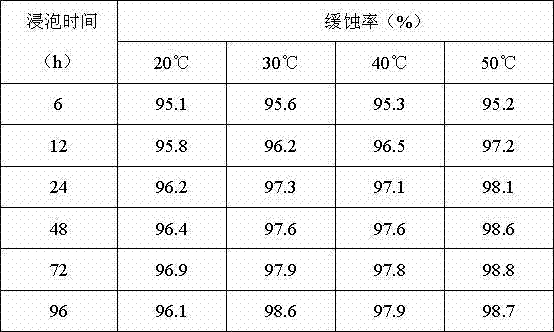

[0037] Embodiment 1——Preparation of Bamboo Leaf Extract

[0038] The bamboo leaf corrosion inhibitor is prepared by extracting golden bamboo leaves, wherein:

[0039] a. After the bamboo leaves are collected, remove the surface impurities, rinse with water to remove the dust on the leaf surface, drain a large amount of water, air-dry them, put them in a blast oven, dry them at 70oC for two days and nights, take them out and cool them down to room temperature, and then crush them. The particle size is about 350 μm;

[0040]b. Take a certain amount of bamboo leaf powder, add a certain volume of ethanol solution (volume fraction: 20% - 80%) (solid-liquid ratio: 1:25), soak at room temperature for 2 hours, and then reflux extraction in a water bath at 80oC for 1.5 hours;

[0041] c. Vacuum filter the refluxed ethanol extract to remove the bamboo leaf powder contained therein, and then rotate the solution at 70°C on a rotary evaporator;

[0042] d Transfer the liquid concentrate...

Embodiment 2

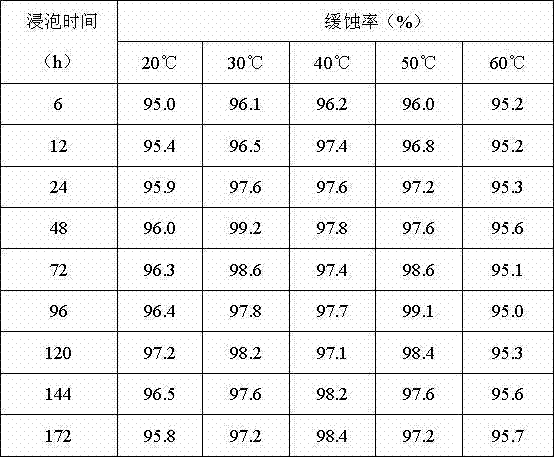

[0044] Embodiment 2——Preparation of Bamboo Leaf Extract

[0045] The bamboo leaf extract is prepared from purple bamboo leaves, wherein:

[0046] a. After the bamboo leaves are collected, remove the surface impurities, rinse with water to remove the dust on the leaf surface, drain a large amount of water and air-dry them, then put them in a blast oven, dry them at a constant temperature of 80oC for two days and nights, take them out and cool them naturally to room temperature, and then pulverize them. The particle size is about 350 μm;

[0047] b. Take a certain amount of bamboo leaf powder, add a certain volume of ethanol solution (volume fraction: 20% - 80%) (solid-liquid ratio: 1:25), soak at room temperature for 1 hour, and then reflux extraction in a water bath at 60°C for 2 hours ;

[0048] c. Vacuum filter the refluxed ethanol extract to remove the bamboo leaf powder contained therein, and then rotate the solution at 70°C on a rotary evaporator;

[0049] d. Transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com