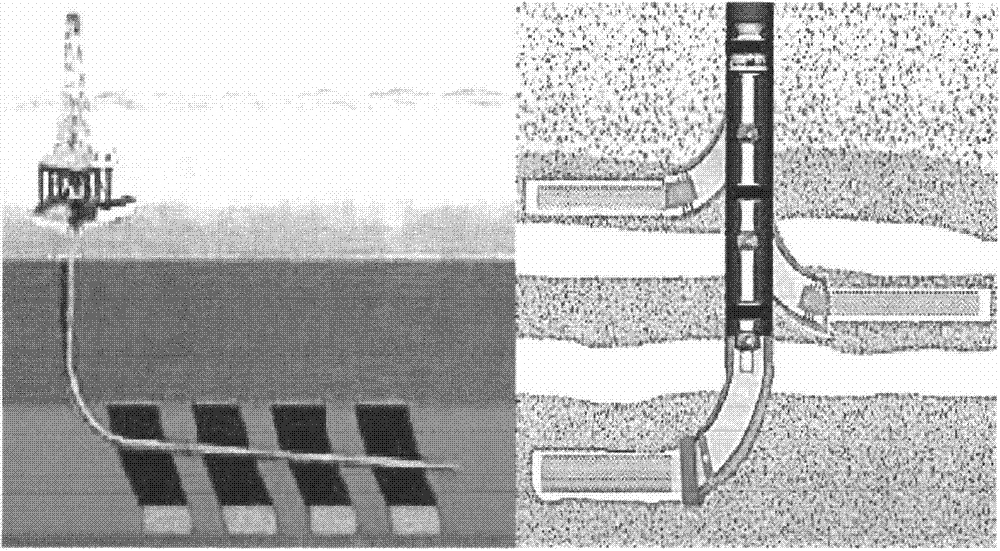

Internal surface local hardening (alloying) eccentric wear prevention oil pipe

An inner surface and alloying technology, which is applied in the field of strengthening the anti-wear layer, can solve the problems of oil well production decline, increased cost of replacing tubing, and increased operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

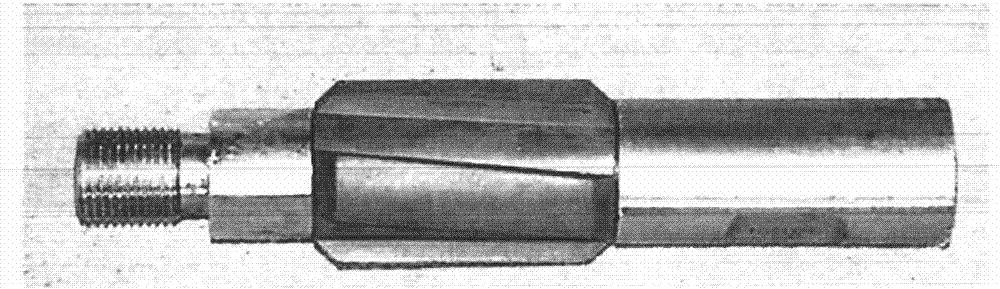

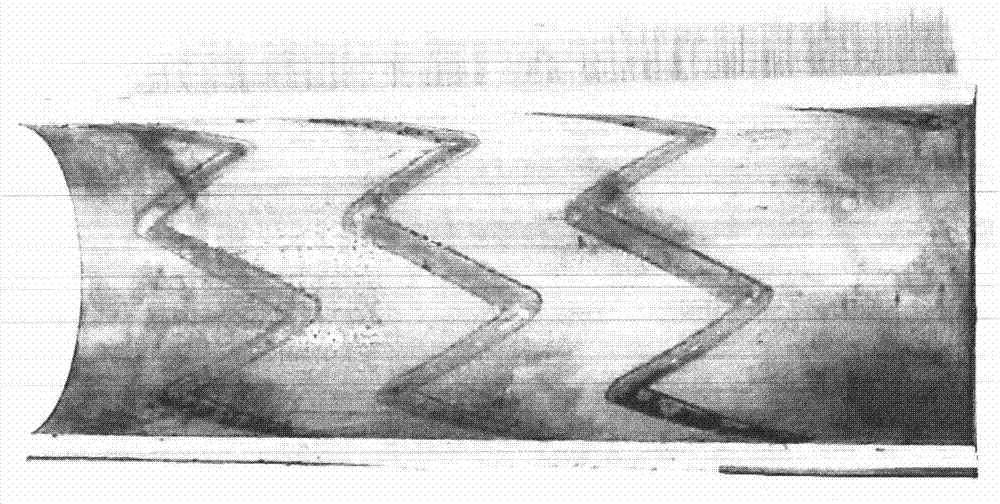

[0010] 1) On a 3-axis CNC lathe with an API standard oil pipe R3 length, a high-power fiber laser is introduced to strengthen the steel pipe that has been derusted on the inner surface. The rotation speed and lead are controlled by the 1st and 2nd axes of the CNC lathe, and the optical power and optical switch are controlled by the third axis.

[0011] 2) During cladding and alloying treatment, alloy powder is blown into one end of the steel pipe with inert gas, and the other end is collected and reused, so as to obtain a strengthening band of complex alloy.

[0012] 3) Using metal cobalt, tungsten, chromium, nickel, yttrium, carbon, and other powders with different ratios to obtain inner surface hardened alloy strips with different properties.

[0013] After different strengthening treatments, the hardness of conventional medium-carbon high-manganese steel oil casing can reach between 55-65 degrees Rockwell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com