A magnetically integrated three-phase filter transformer

A transformer and magnetic integration technology, applied in the field of transformers, to achieve the effect of saving magnetic cores, saving iron cores, and saving copper wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

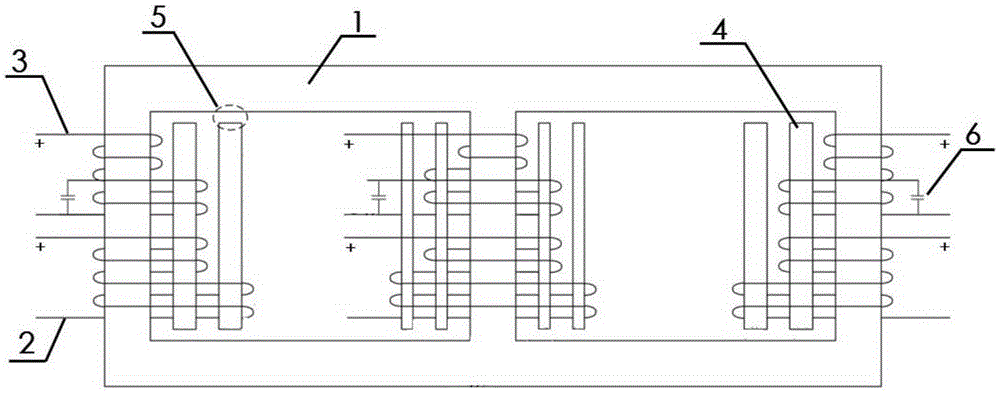

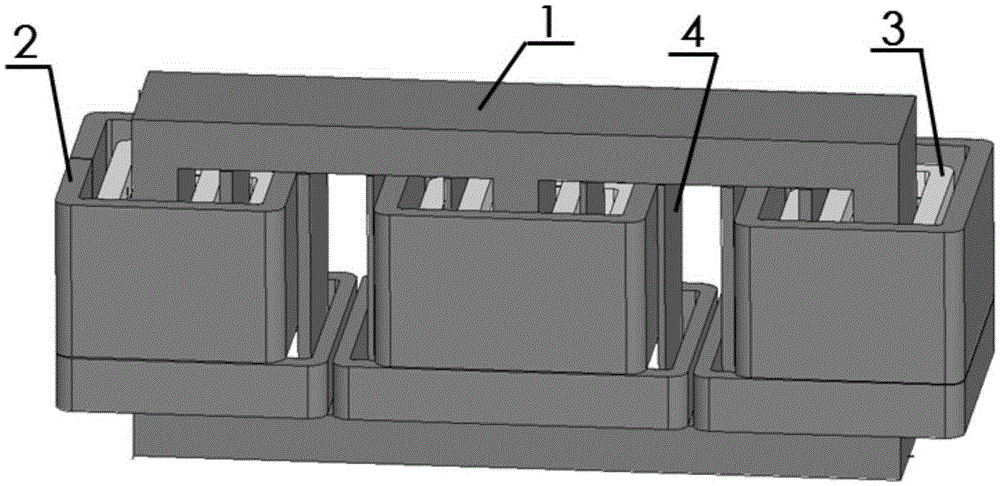

[0023] see figure 1 and figure 2 , a magnetically integrated three-phase filter transformer, including a transformer core window 1, a high-voltage winding coil 2, a low-voltage winding coil 3, an air gap 5, a filter capacitor 6 and a flux leakage branch piece 4; the core window 1 of the transformer is provided with The flux leakage branch piece 4, there is an air gap 5 between the flux leakage branch piece 4 and the upper and lower iron yokes, the high voltage winding coil 2 and the low voltage winding coil 3 are respectively wound between the iron core column and the flux leakage branch piece 4, wherein the low voltage Winding 3 is inside, high-voltage winding 2 is outside; filter capacitor 6 is connected in parallel with low-voltage winding coil 3

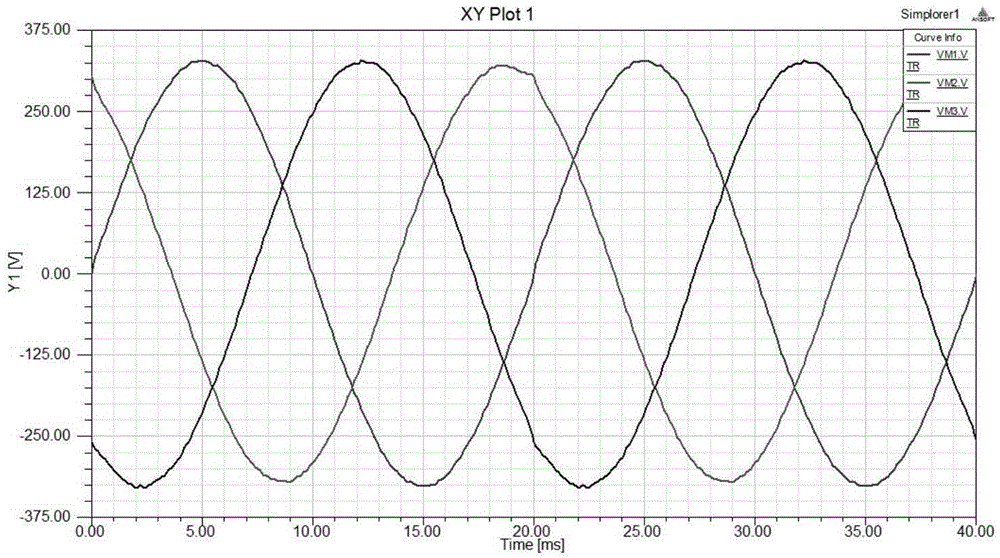

[0024] The provided magnetically integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com