Preparation method of flexible substrate silicon nanowire heterojunction solar cell

A technology of silicon nanowires and flexible substrates, applied in the field of solar cells, can solve problems such as impossible industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

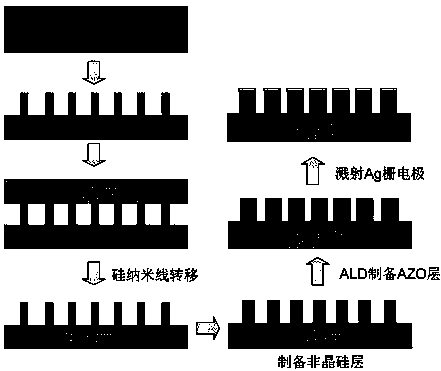

[0026] Example one Copper foil / p-type monocrystalline silicon nanowire / amorphous silicon passivation layer / n-type silicon thin film / AZO / Ag solar cell

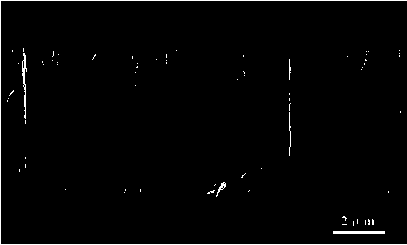

[0027] 1. Preparation of single crystal silicon nanowires with a length of 6 μm:

[0028] A (100) doped p-type silicon wafer is selected, with a resistivity of 1.5 Ωcm and a thickness of 180 μm.

[0029] Dip the silicon wafer into acetone and ethanol for 10 min and ultrasonically clean it to remove the organic impurities on the surface, wash it with deionized water; then immerse it in concentrated H 2 SO 4 :H 2 o 2 =3:1 (volume ratio) mixed solution was boiled at 130°C for 10 min, rinsed with deionized water, and dried with nitrogen gas for later use.

[0030] The easy-to-transfer silicon nanowire arrays were prepared by secondary etching. First, the silicon wafer was immersed in 0.005M AgNO 3 and 5M HF mixed solution for 1min, that is, spread a layer of silver on the surface of the silicon wafer, rinse with deionized wa...

example 2

[0042] Example two Copper foil / n-type monocrystalline silicon nanowire / amorphous silicon passivation layer / p-type silicon film / AZO layer / Ag solar cell

[0043] 1. Preparation of single crystal silicon nanowires with a length of 8 μm:

[0044] A (100) doped n-type silicon wafer is selected, with a resistivity of 1.5 Ωcm and a thickness of 180 μm.

[0045] The steps are the same as step 1 in Example 1, but the corrosion time is 1.3h, as follows:

[0046] Dip the silicon wafer into acetone and ethanol for 10 min and ultrasonically clean it to remove the organic impurities on the surface, wash it with deionized water; then immerse it in concentrated H 2 SO 4 :H 2 o 2 =3:1 (volume ratio) mixed solution was boiled at 130°C for 10 min, rinsed with deionized water, and dried with nitrogen gas for later use.

[0047] The easy-to-transfer silicon nanowire arrays were prepared by secondary etching. First, the silicon wafer was immersed in 0.005M AgNO 3 and 5M HF mixed solution fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com