Water circulating system and method of PM2.5 flue gas treatment tower

A technology of circulation system and water circulation, applied in separation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve the effect of increasing the difficulty and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

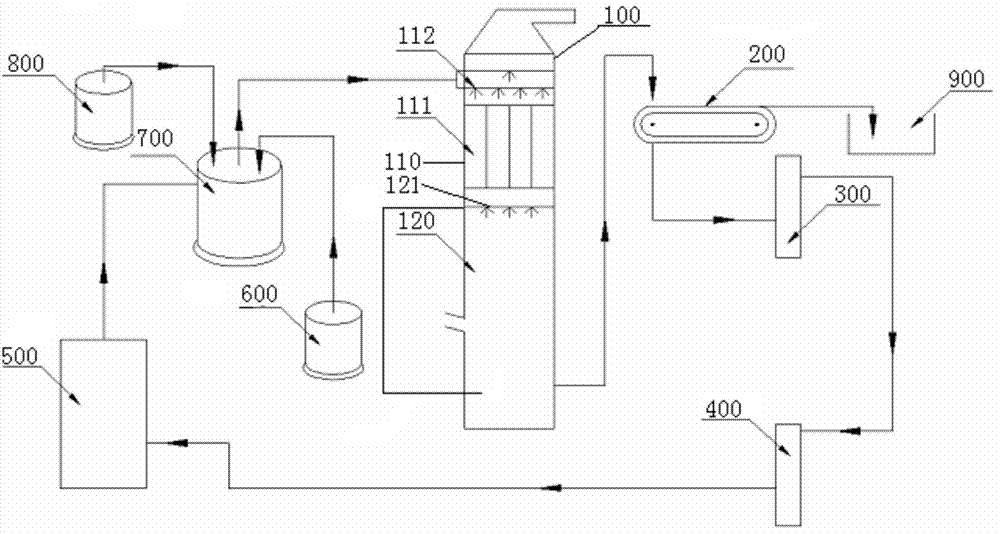

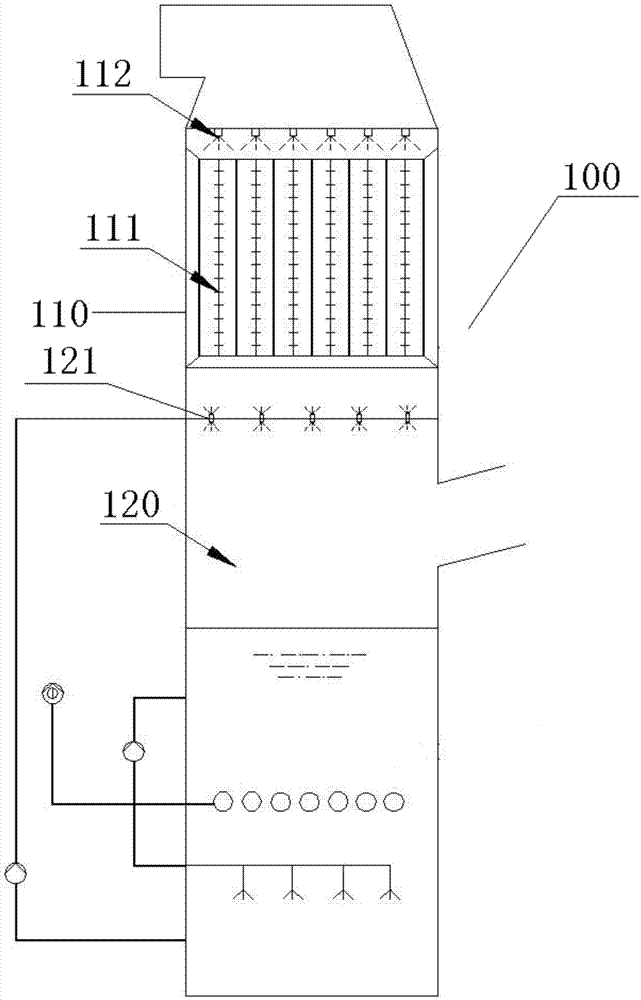

[0046] figure 1 It is a structural schematic diagram of the water circulation system of the PM2.5 flue gas treatment tower of the present invention. Such as figure 1 As shown, a PM2.5 flue gas treatment tower water circulation system proposed in this embodiment includes: a flue gas treatment tower 100 integrating wet desulfurization and wet electrostatic precipitator, used for dehydration treatment of the exhaust gas discharged from the flue gas treatment tower 100 A dehydrator 200 for mixed waste liquid, a gypsum cyclone station 300 for removing particulate matter in the mixed waste liquid, a sedimentation tank 400 for adding coagulant and gravity sedimentation to the mixed waste liquid, and used for The filter 500 for multi-stage filtration of the mixed waste liquid, the pH adjustment tank 600 for adjusting the pH value of the mixed waste liquid, the circulating water tank 700 for providing circulating water for the flue gas treatment tower, and the Supplement the water su...

Embodiment 2

[0052] This embodiment proposes a PM2.5 flue gas treatment tower water circulation method, which is used to process and recycle the mixed waste liquid mixed and discharged from the flushing water in the electric field section of the flue gas treatment tower and the gypsum slurry in the desulfurization section. figure 1 shown, including the following steps:

[0053] Dehydration step: the mixed waste liquid is transported to the gypsum dehydration belt used as dehydrator 200 for dehydration, the gypsum is transported to the gypsum storage room 900, and the filtrate after pressure filtration by the gypsum dehydration belt is input into the next step.

[0054] Secondary particle removal step: the filtrate is input into the gypsum cyclone station 300 for secondary particle removal.

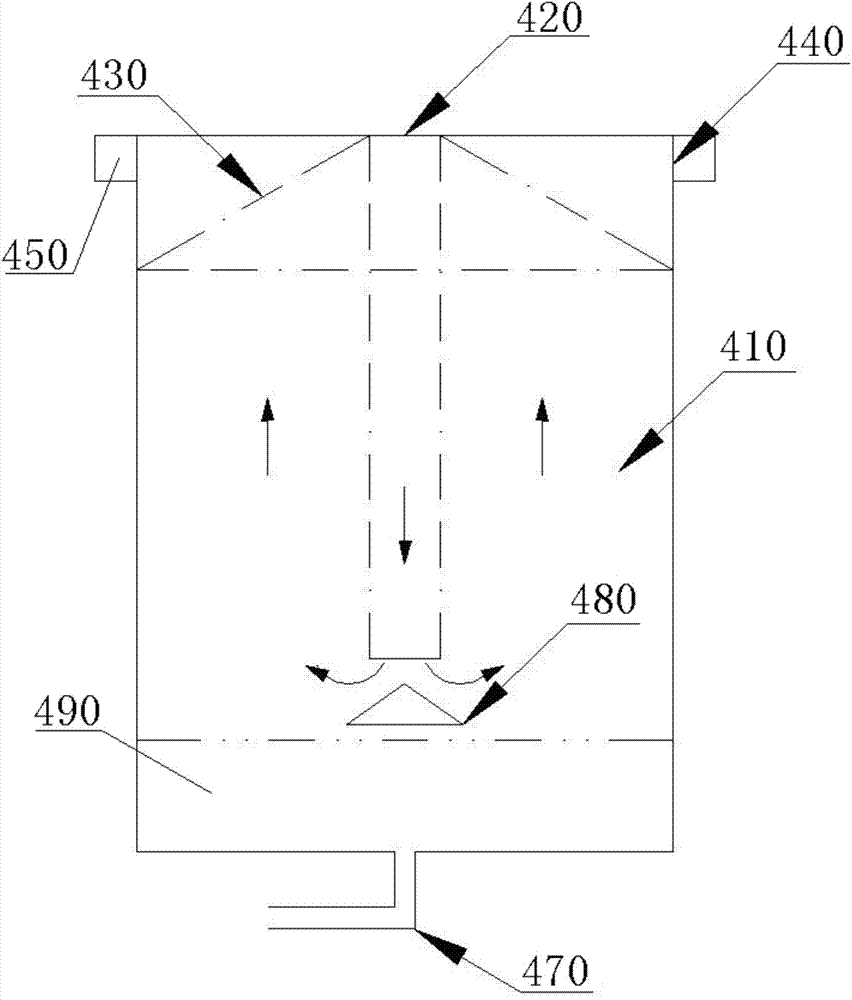

[0055] Sedimentation step: the liquid after the secondary particle removal step is input into the sedimentation tank 400, and the particles in the liquid are partially removed by sedimentation under th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap