Preparation method and application of magnetic sludge-based ozone catalyst

A catalyst and sludge technology, which is applied in the fields of waste resource utilization and environmental engineering, can solve the problem of low catalyst activity, and achieve the effects of simple operation, low energy consumption and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

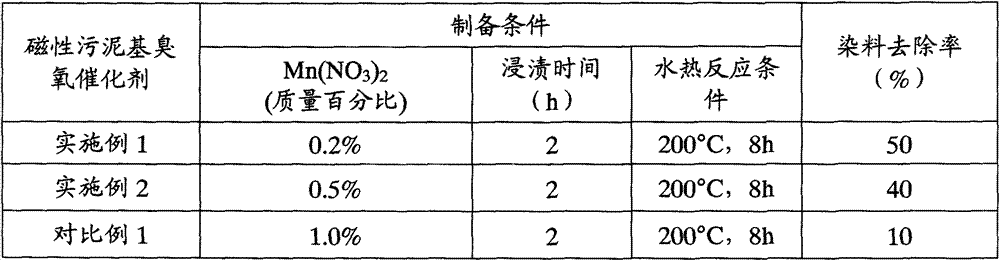

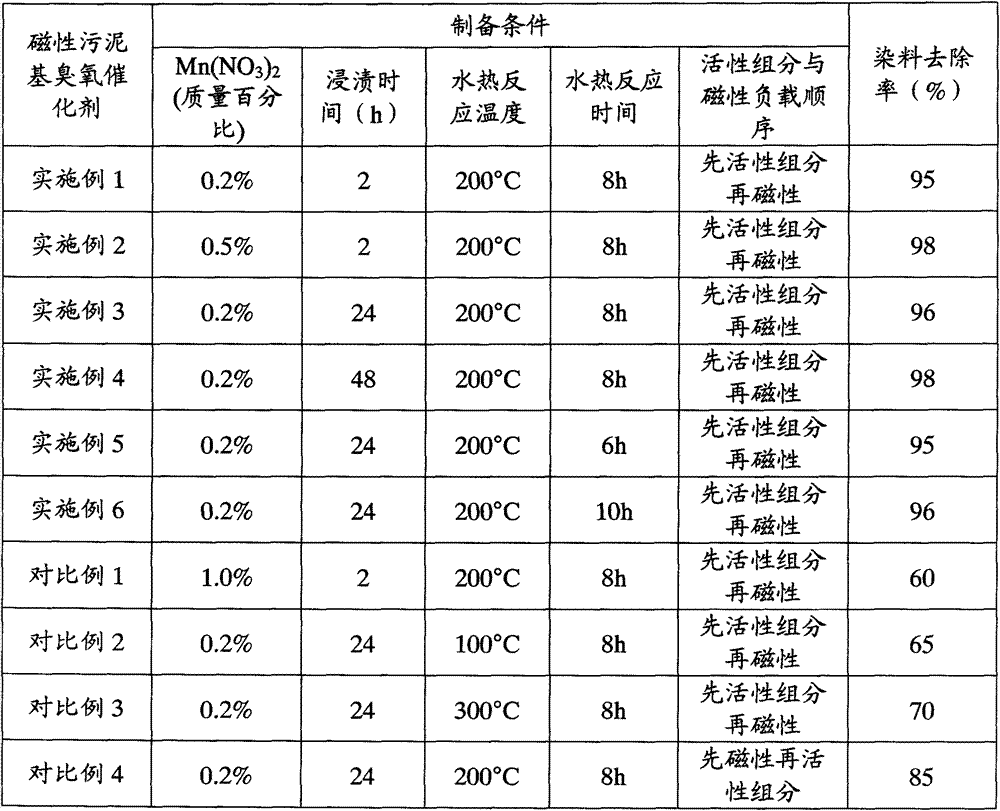

Embodiment 1

[0026] The preparation method of the magnetic sludge base ozone catalyst of the embodiment of the present invention, described preparation method comprises the following steps:

[0027] (A1) Add 50mL of 0.2% (mass percentage) manganese nitrate solution to 3.5g of modified sludge, stir and mix, then let it stand for immersion for 2 hours, transfer it to the ozone reaction device, and inject ozone (flow rate is less than 0.1L / min), And vigorously stirred for 150min, then poured the reaction liquid into a high-pressure reaction kettle, placed in an oven at a temperature of 200°C, and took 8h. After the hydrothermal reaction, it was naturally cooled to room temperature, washed with water, and dried to obtain a dirty mud-based catalyst;

[0028] (A2) Weigh FeCl 3 .6H 2 O: Dissolve 5.40g in 20mL distilled water and weigh FeSO at the same time 4 ·7H 2O: 2.78g dissolved in 20mL distilled water;

[0029] FeCl 3 Aqueous solution, FeSO 4 Mix the aqueous solution while vigorously s...

Embodiment 2

[0033] The preparation method of the magnetic sludge base ozone catalyst of the embodiment of the present invention, described preparation method comprises the following steps:

[0034] (A1) Add 50mL of 0.5% (mass percentage) manganese nitrate solution to 3.5g of modified sludge, stir and mix, then let it stand for immersion for 2h, transfer to the ozone reaction device, and pass into ozone (flow rate is less than 0.1L / min), And vigorously stirred for 150min, then poured the reaction liquid into a high-pressure reaction kettle, placed in an oven at a temperature of 200°C, and took 8h. After the hydrothermal reaction, it was naturally cooled to room temperature, washed with water, and dried to obtain a dirty mud-based catalyst;

[0035] (A2) Weigh FeCl 3 .6H 2 O: Dissolve 5.40g in 20mL distilled water and weigh FeSO at the same time 4 ·7H 2 O: 2.78g dissolved in 20mL distilled water;

[0036] FeCl 3 Aqueous solution, FeSO 4 Mix the aqueous solution while vigorously stirr...

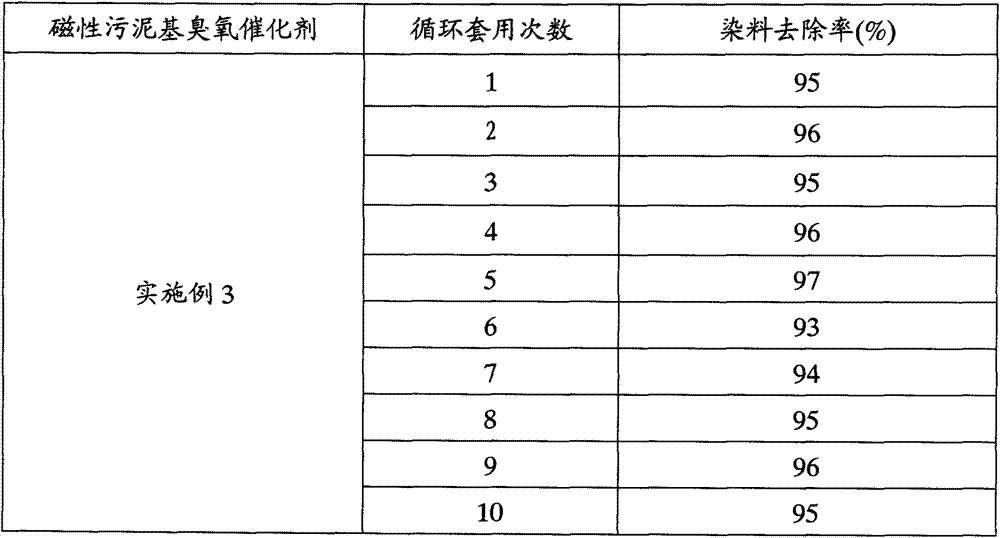

Embodiment 3

[0040] The preparation method of the magnetic sludge base ozone catalyst of the embodiment of the present invention, described preparation method comprises the following steps:

[0041] (A1) Add 50mL of 0.2% (mass percentage) manganese nitrate solution to 3.5g of modified sludge, stir and mix, then let it stand for immersion for 24 hours, transfer to the ozone reaction device, and pass through ozone (flow rate is less than 0.1L / min), And vigorously stirred for 150min, then poured the reaction liquid into a high-pressure reaction kettle, placed in an oven at a temperature of 200°C, and took 8h. After the hydrothermal reaction, it was naturally cooled to room temperature, washed with water, and dried to obtain a dirty mud-based catalyst;

[0042] (A2) Weigh FeCl 3 ·6H 2 O: Dissolve 5.40g in 20mL distilled water and weigh FeSO at the same time 4 ·7H 2 O: 2.78g dissolved in 20mL distilled water;

[0043] FeCl 3 Aqueous solution, FeSO 4 Mix the aqueous solution while vigorou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com