Disposable scaling powder used for high-temperature soldering

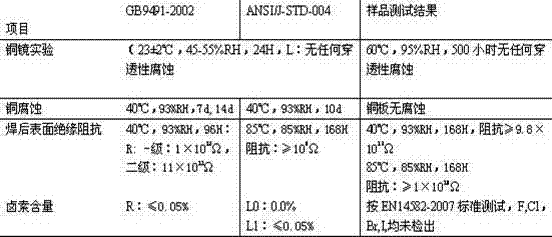

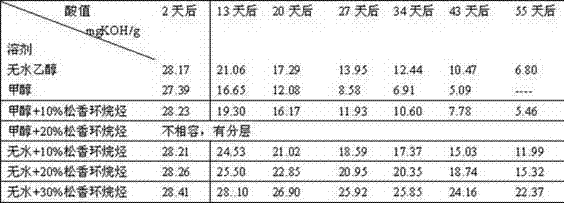

A flux and soldering technology, applied in the field of materials, can solve the problems of high flux corrosion, high dosage, low impedance, etc., and achieve high residual insulation resistance after welding, high storage stability, and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A no-clean flux for high temperature soldering, the flux includes the following components by weight percentage:

[0039] Modified rosin 5%

[0040] Adipic acid active agent: 0.6%

[0041] Sebacic acid active agent: 1.2%

[0042] Benzotriazole corrosion inhibitor: 0.2%

[0043] Non-ionic surfactant SURFYNOL 104 0.2%

[0044] Rosin cycloalkane 30%

Embodiment 2

[0046] Embodiment 2: A no-clean flux for high-temperature soldering, the flux includes the following components by weight percentage:

[0047] Modified rosin 3%

[0048] Suberic acid active agent 0.3%

[0049] Dodecanoic acid active agent 1.6%

[0050] Alcohol ether surfactant 0.5%

[0051] Imidazoline corrosion inhibitor 0.15%

[0052] Rosin cycloalkane 20%

[0053] Isopropanol solvent balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com