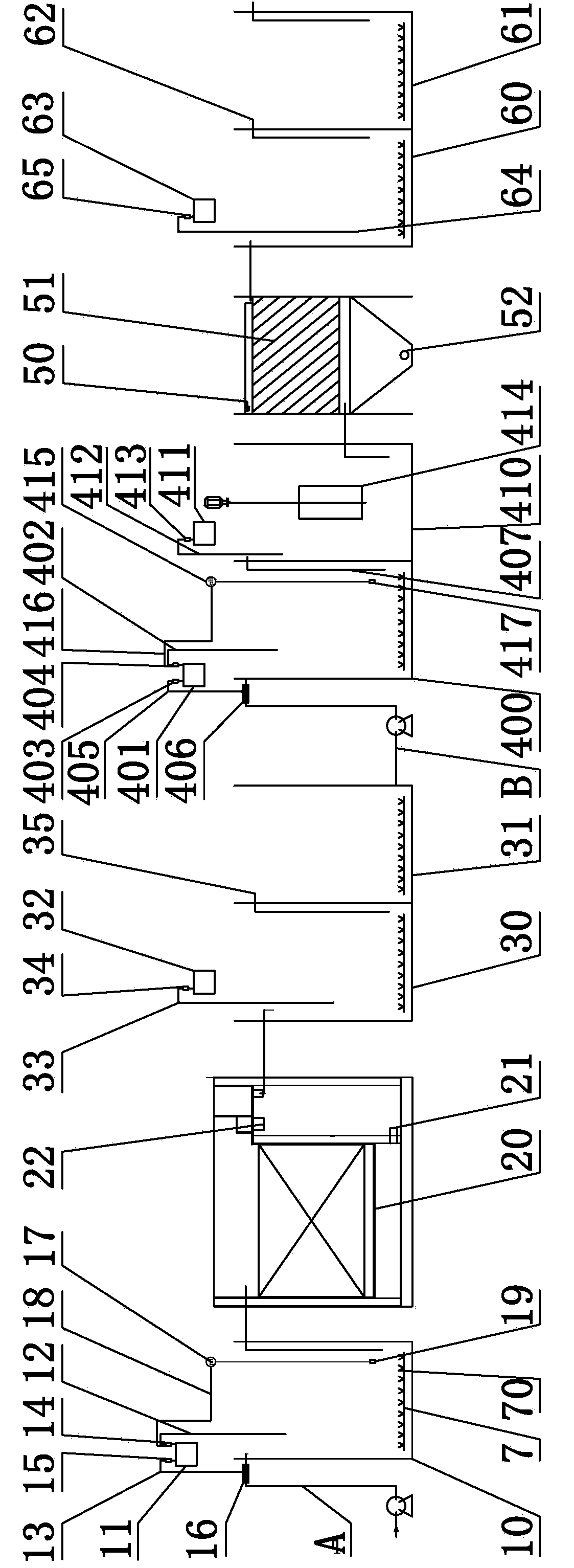

Industrial sewage treatment method and integrated apparatus for same

A technology of industrial sewage and treatment methods, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems such as good, to achieve the effect of enhancing the range of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Handle 1.0m 3 Volume of pesticide and chemical wastewater, water quality index:

[0061] COD25000mg / l; PH9; NH3-N1800mg / l; CN-900mg / l;

[0062] Add 500ml of sulfuric acid solution to adjust the pH of the wastewater to 2.0;

[0063] Pass a current of 3.5A, a voltage of 90V, and catalyze for 20 minutes;

[0064] Add 10L of hydrogen peroxide, mix with hydrogen peroxide concentration 25%, and aerate for 40 minutes;

[0065] Add 350ml of sodium hydroxide to adjust the pH of the wastewater to 9.0; add 0.2‰ PAM flocculant;

[0066] After the precipitation overflows, add 5ml of sodium hypochlorite with a concentration of 20% to mix, and aerate for 30min.

[0067] The wastewater quality indicators after treatment are COD1300mg / l, PH9, NH3-N 620mg / l, CN-4.0 mg / l.

Embodiment 2

[0069] Process 1m 3 Volume of chemical nickel wastewater: indicators of wastewater before treatment:

[0070] Ni2+60mg / l; COD500mg / l;

[0071] Add 300ml of sulfuric acid solution to adjust the pH of the wastewater to 2.0;

[0072] Pass a current of 4.0A, a voltage of 150V, and catalyze for 20 minutes;

[0073] Add 4L of hydrogen peroxide, mix with hydrogen peroxide concentration 25%, and aerate for 40 minutes;

[0074] Add 300ml of sodium hydroxide to adjust the pH of the wastewater to 11.0; add 0.2‰ PGA flocculant;

[0075] Water quality index of treated wastewater: Ni2+0.05mg / l, COD100mg / l.

Embodiment 3

[0077] Process 1m 3 Volume of printing and dyeing wastewater: COD2860mg / l in wastewater before treatment;

[0078] Add 200ml of sulfuric acid solution to adjust the pH of the wastewater to 2.5;

[0079] Introduce a current of 4.0A, a voltage of 125V, and catalyze for 20 minutes;

[0080] Add 2.5L of hydrogen peroxide, mix with hydrogen peroxide concentration 25%, and aerate for 40 minutes;

[0081] Add 100ml of sodium hydroxide to adjust the pH of the wastewater to 8.0; add 0.2‰ flocculant (PAM);

[0082] COD464mg / l in wastewater after treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com