Pressure oxidation leaching-out method for nickel-cobalt oxide ore

A technology of oxidized ore and leaching method, which is applied in the field of nickel-cobalt oxidized ore pressure oxidation leaching method, can solve problems such as environmental pollution, achieve the effects of reducing production costs, being conducive to environmental protection, and expanding the scope of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

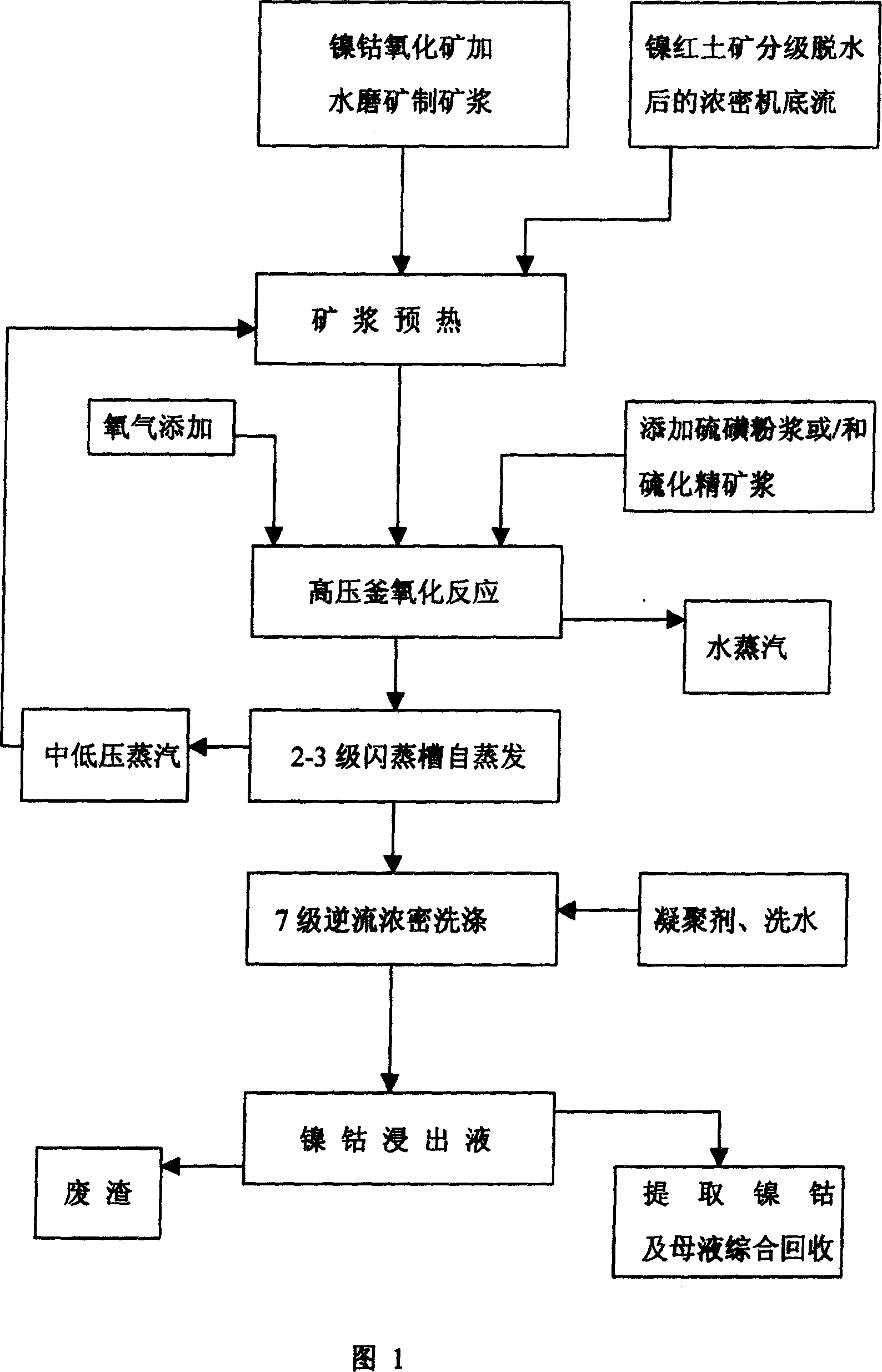

Method used

Image

Examples

example 1

[0030](1). Grinding nickel-cobalt oxide ore slurry, with nickel-cobalt oxide ore 108.3g, the composition is (%wt) Ni1.70, Co0.046, Fe11.2, MgO27.0, Si35.22; add water and grind into The pulp is sent to the pulp preheater;

[0031] (2). Add sulfur slurry, preheat the nickel-cobalt oxide ore slurry to a temperature of 180°C in the slurry preheater, and then add sulfur slurry. The added amount is 37.7g of elemental sulfur in the sulfur slurry and 600ml of water;

[0032] (3). Pump the nickel-cobalt oxidized ore slurry added with sulfur powder after preheating into the autoclave. When the temperature in the autoclave is 180°C, oxygen is charged into the autoclave, and the oxygen partial pressure is 0.7MPa. The stirring line speed is 3.0m / s, the elemental sulfur of the sulfur slurry oxidizes with the oxygen filled in the kettle to generate sulfuric acid, and the sulfuric acid reacts with the nickel-cobalt oxide ore at the same time, leaching the corresponding components and compone...

Embodiment 2

[0038] (1). The thickener underflow pulp after the graded dehydration of nickel laterite ore is used. The amount of nickel-cobalt oxide ore is 134.6g, and the composition is (%wt) Ni0.95, Co0.17, Fe42.2, Mg1.44, Mn1. 23, Cr0.37, Al5.12, Si4.90 are sent directly to the pulp preheater;

[0039] (2). Add sulfide ore concentrate slurry, preheat the nickel-cobalt oxide ore slurry to a temperature of 180°C in the slurry preheater, add 33.4g of cobalt-sulfur concentrate, and its composition is Ni0.083%, Co0.14 %, Cu0.36%, S37.42%, add 600ml of water and mix with the nickel-cobalt oxide slurry and preheat together;

[0040] (3). Pump the nickel-cobalt oxide ore slurry added with cobalt-sulfur concentrate slurry after preheating into the autoclave, and fill the autoclave with oxygen when the temperature in the autoclave is 180°C, and the oxygen partial pressure is 0.9MPa. The stirring line speed in the kettle is 3.0m / s, the elemental sulfur of the cobalt-sulfur concentrate pulp and th...

Embodiment 3

[0045] (1). Grinding the nickel-cobalt oxide ore slurry, the nickel-cobalt oxide ore 168g, the composition is (%wt) Ni0.95, Co0.17, Fe42.2, Mg1.44, Mn1.23, Cr0.37, Al5 .12, Si4.9 is ground into pulp after adding water and sent to the pulp preheater;

[0046] (2).Add sulfide ore concentrate slurry and sulfur powder slurry, preheat the nickel-cobalt oxide ore slurry to a temperature of 180°C in the slurry preheater, add 80.7g of cobalt-sulfur concentrate slurry, the composition is: Ni0.083 %, Co0.14%, Cu0.36%, S37.42%, add 30.2g of sulfur slurry, add 600ml of water, mix with cobalt-sulfur concentrate slurry and nickel-cobalt oxide slurry and preheat together;

[0047] (3). After preheating, the nickel-cobalt oxide ore slurry added with cobalt-sulfur concentrate slurry and sulfur powder slurry is pumped into the autoclave, and oxygen is charged into the autoclave when the temperature in the autoclave is 180°C. The partial pressure is 1.0MPa, the linear velocity of stirring in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com