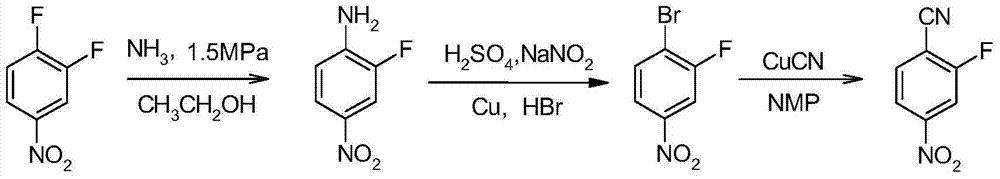

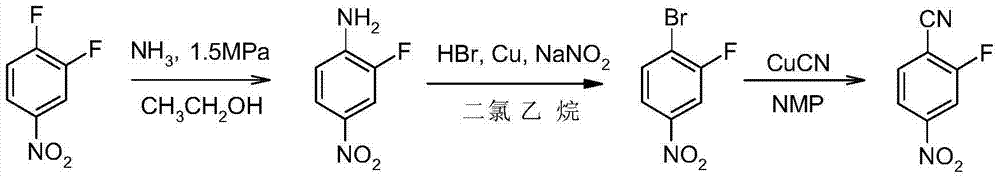

Production method of 2-fluorine-4-nitrobenzonitrile

A technology of nitrobenzonitrile and clean production, which is applied in the direction of cyanide reaction preparation and organic chemistry. rate-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] The preparation of example 1,2-fluoro-4-nitroaniline

[0028] Put 300L of industrial alcohol, 187.5L of 28% ammonia water, 6.8Kg of cuprous oxide and 120Kg of 3,4-difluoronitrobenzene into the high-pressure reactor, mix the above materials, raise the temperature to 120°C and control the pressure of the reactor at 1.7 MPa, heat preservation reaction for 18 hours, GC tracking reaction is basically over; after cooling down, the material is pressed into water, and 113.0Kg of yellow solid 2-fluoro-4-nitroaniline crude product is precipitated, the filter cake is washed and dried for later use, and its content is 99.61 %(GC).

[0029] Example 2, (1), put 250.0L of hydrobromic acid and 13.0Kg of copper powder into a 1000L reactor, stir and heat up to 100°C, keep warm for 3h, then cool down to 55°C; add 75.0L of Water, 56.2Kg of 2-fluoro-4-nitroaniline prepared in Example 1, and 100.0L of dichloroethane were added and kept at 55°C for 2 hours, and then 38.0Kg of 70.0L aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com