Preparation method of macroporous weakly acidic cation exchange resin

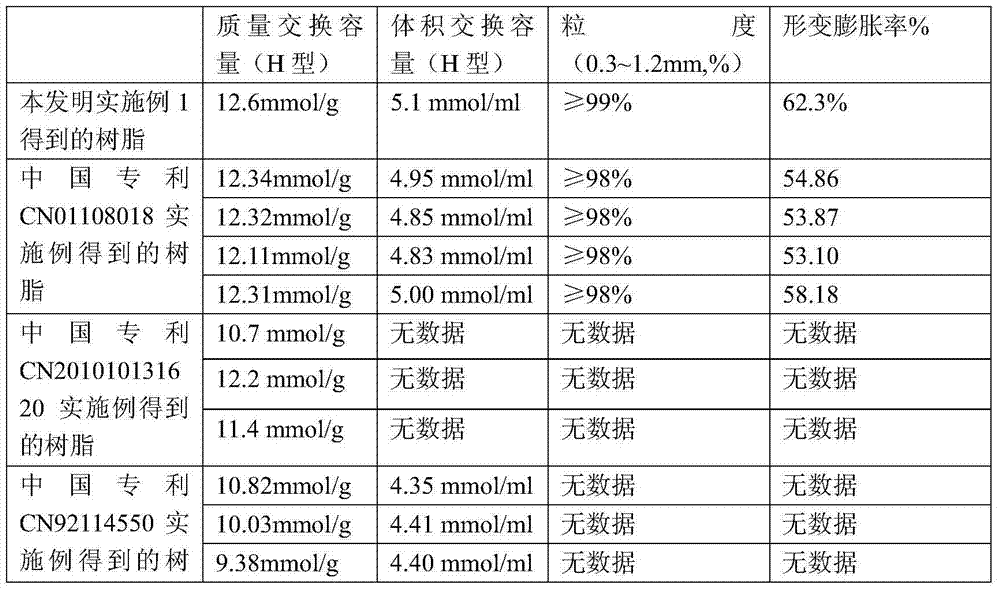

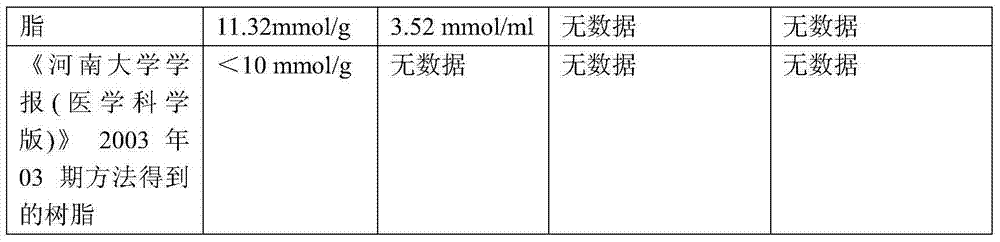

A technology of cation exchange and macroporous resin, which is applied in the field of polymer chemistry and can solve the problems of poor product appearance and small exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, take vinylphenol 50g, styrene 30g, acrylonitrile 500g, methyl acrylate 300g, triallyl isocyanurate 80g by weight as monomers; get 336g of toluene as porogen, and take another 2.88g of benzoyl peroxide and 4.8g of azobisisobutyronitrile were used as initiators and mixed to prepare phase A.

[0030] Step 2, take saturated sodium chloride solution as phase B.

[0031] Step 3, put phase A into phase B, the ratio is 1:0.5, start stirring, the stirring speed is 100 rpm, stir for 0.5 hours, heat up to 70°C to react, continue to react for 8 hours, heat up to boiling and reflux, and continue to react After 8 hours, cool and filter to obtain resin microspheres.

[0032] In step 4, the resin microspheres are washed with deionized water until the lotion is clear and transparent, and then washed with hot ethanol until there is no toluene smell to obtain a semi-finished macroporous resin.

[0033] Step 5, take the macroporous resin semi-finished product, add 25% sodium hydr...

Embodiment 2

[0036] Step 1, take vinylphenol 80g, styrene 50g, acrylonitrile 300g, methyl acrylate 350g, triallyl isocyanurate 80g by weight as monomers; get 344g of toluene as porogen, and take another 4.3 g of benzoyl peroxide and 4.3 g of azobisisobutyronitrile were used as initiators and mixed to prepare Phase A.

[0037] Step 2, take saturated sodium chloride solution as phase B.

[0038] Step 3, put phase A into phase B, the ratio is 1:0.8, start stirring, the stirring speed is 120 rpm, stir for 1 hour, heat up to 80°C to react, continue to react for 10 hours, heat up to boiling and reflux, and continue to react After 10 hours, cool and filter to obtain resin microspheres.

[0039] In step 4, the resin microspheres are washed with deionized water until the lotion is clear and transparent, and then washed with hot ethanol until there is no toluene smell to obtain a semi-finished macroporous resin.

[0040] Step 5, take the macroporous resin semi-finished product, add 30% sodium hydr...

Embodiment 3

[0043] Step 1, take vinylphenol 100g, styrene 50g, acrylonitrile 500g, methyl acrylate 400g, triallyl isocyanurate 70g by weight as monomers; get 336g of toluene as porogen, and take another Azobisisobutyronitrile with a monomer weight of 5.6 g was used as an initiator, and phase A was prepared by mixing.

[0044] Step 2, take saturated sodium chloride solution as phase B.

[0045] Step 3, put phase A into phase B, start stirring, the stirring speed is 150 rpm, stir for 1 hour, heat up to 65°C to react, continue to react for 9 hours, heat up to boiling and reflux, continue to react for 10 hours, cool and filter to obtain resin Microspheres.

[0046] In step 4, the resin microspheres are washed with deionized water until the lotion is clear and transparent, and then washed with hot ethanol until there is no toluene smell to obtain a semi-finished macroporous resin.

[0047] Step 5, take the macroporous resin semi-finished product, add 20% sodium hydroxide solution twice its w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com