Cellulose solution, cellulose dissolution method and regenerated cellulose

A cellulose solution and cellulose technology, applied in the field of regenerated cellulose, can solve the problems of limited industrial utilization process, complexity, and huge influence of ionic liquid solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0189] described in this patent can be used with CO 2 One or two or more compounds that form switch-type reversible ionic compounds, we press the chemical equivalent tetramethylguanidine (TMG) and ethylene glycol in DMSO, in CO 2 The formation of switch-type reversible ionic compounds in the atmosphere is illustrated. This type of CO 2 The formation of switch-type reversible ionic compounds is the key to the ability of the mixed system described in the present invention to dissolve cellulose. We validated [TMGH] by NMR techniques 2 2+ [O 2 COCH 2 CH 2 OCO 2 ] 2- Formation. For specific test results, see Figure 1 , Figure II .

Embodiment 2

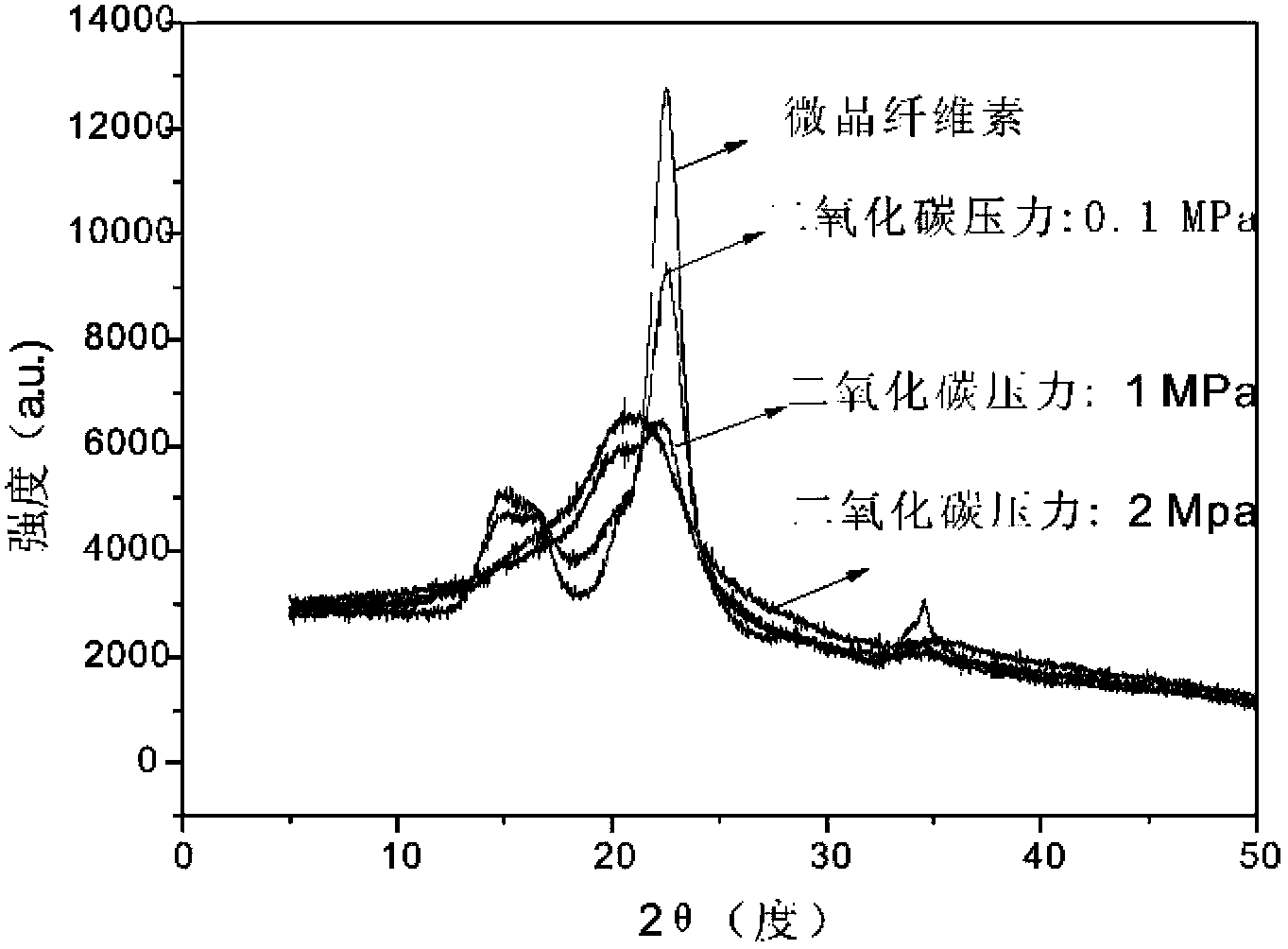

[0191] The dissolving system described in the present invention, its dissolving capacity can be adjusted by CO 2 The structure of the switch-type ionic compound, the dissolution temperature and the dissolution time are adjusted. When the total mass of the solution is set to 20.0 g, it will be compatible with CO 2 One or two or more compounds that form reversible ionic compounds and DMSO are added to the reactor at a certain molar ratio, a certain amount of microcrystalline cellulose is added to the mixed system, the reactor is covered and closed, and 2MPa CO 2 Gas, under stirring, heated to a certain temperature, dissolved for 12 hours, released to obtain a cellulose solution. The experimental results are summarized in the following table:

[0192]

[0193]

[0194]

[0195] From the table, we found that the system composed of strong organic base guanidine compounds and squint compounds and alcohol compounds, such as methanol, ethanol, ethylene glycol, and glycerin,...

Embodiment 3

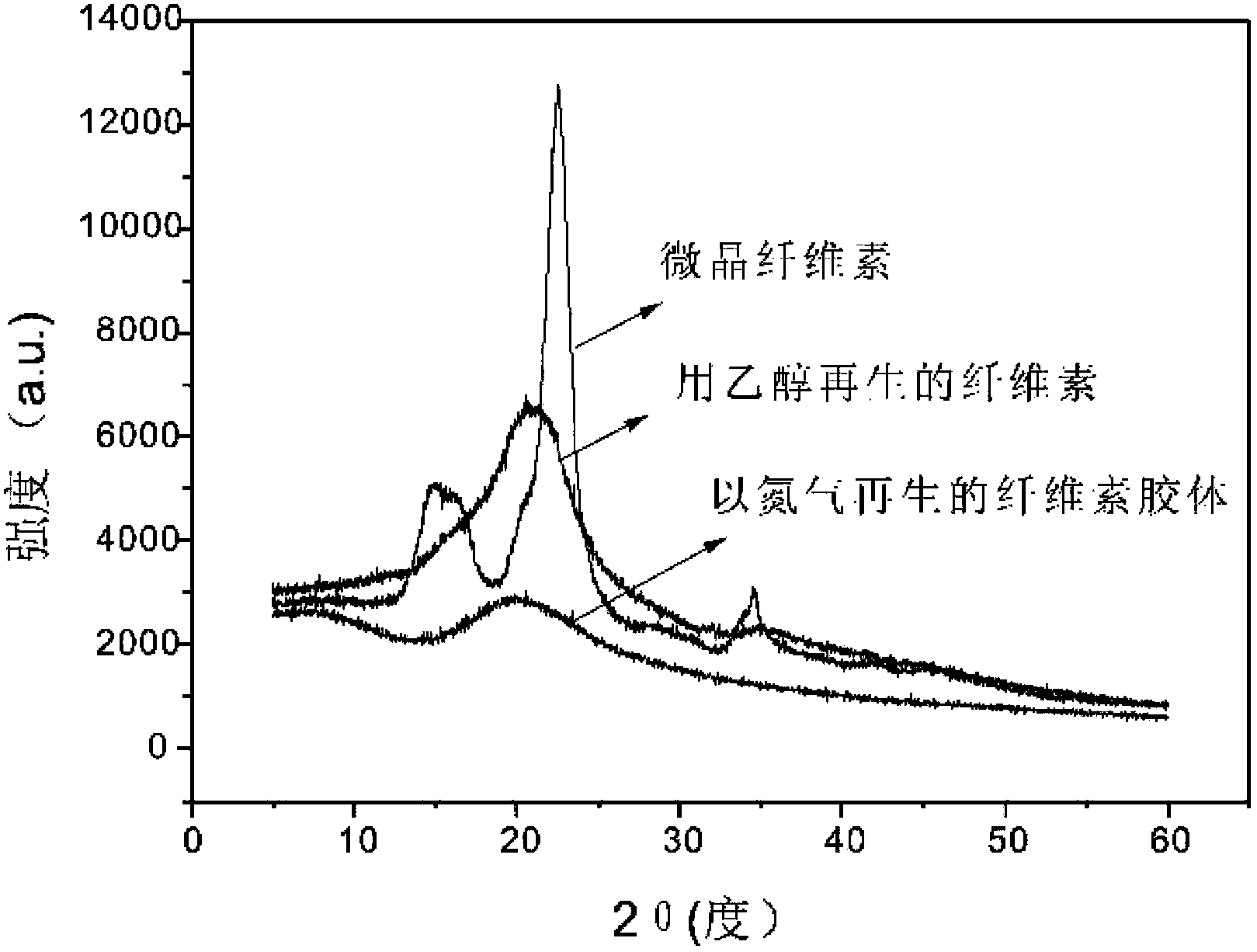

[0197] The patent described by using organic solvents with good swelling effect on cellulose and CO 2 switch-type ionic compound mixture, although this type of solvent is for CO 2 It is not necessary for the switch-type ionic compound to dissolve cellulose, but the use of this type of solvent can greatly accelerate the dissolution rate and solubility, and at the same time reduce the viscosity of the obtained cellulose solution, thereby greatly improving its subsequent processing and use.

[0198] Mix tetramethylguanidine (0.036 moles, 4.14 grams), ethylene glycol (0.018 moles, 1.14 grams), a certain amount of organic solvent and 1.6 grams of microcrystalline cellulose, add to the reaction kettle, cover and seal the reaction kettle, and pass into P at a certain pressure CO2 =2MPa gas, under stirring, heat the system to 80°C, dissolve for 10 hours, and obtain a cellulose solution. The experimental results are summarized as follows:

[0199]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com