PVDF (Polyvinylidene Fluoride) fluorocarbon powder coating and preparation method thereof

A powder coating and fluorocarbon technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve problems such as large energy consumption and environmental pollution, and achieve the effect of overcoming difficulty in crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 60 kg of PVDF resin, 5 kg of epoxy resin E12; 5 kg of acrylic resin; 15 kg of titanium dioxide; 1 kg of benzoin; 2 kg of BYK-307 leveling agent; German BYK BYK-4510 adhesion promoter 1 kg of agent; 2 kg of fluororubber 246 and 1 kg of boric acid. After the raw materials are melted and mixed at about 120 ° C, they are pressed into tablets, and then crushed into particles with a diameter of 0.5-1.5 cm, and then put into Chengdu Kunsen Micro-Nano Technology Co., Ltd. The KSBR-200 target jet mill produced by the company is finely ground, and the particles with a particle size of ≤30 μm are screened to obtain the finished PVDF fluorocarbon powder coating. The performance test is shown in Table 1:

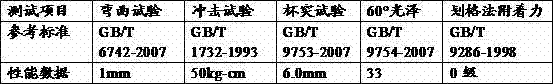

[0032] Table 1. Fluorocarbon powder coating film performance test result table of embodiment 1

[0033]

[0034] The powder coating is applied to the metal surface with an electrostatic spray gun, and baked at 240°C for 10 minutes. The resulting coating has been subjected t...

Embodiment 2

[0036] Add 65 kg of PVDF resin, 5 kg of epoxy resin E14; 5 kg of acrylic resin; 18 kg of cobalt green; 1 kg of benzoin; 2 kg of BYK-310 leveling agent; German BYK BYK-4510 adhesion promoter 1 kg of agent; 3 kg of fluorine rubber 26 and 2 kg of boric acid. After the raw materials are melted and mixed at about 110 ° C, they are pressed into tablets, and then crushed into particles with a diameter of 1-1.5 cm, and then put into a target jet mill to grind , screened to obtain particles with a particle size of 15-30 μm to obtain the finished PVDF fluorocarbon powder coating, and the performance test is shown in Table 2:

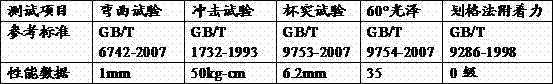

[0037] Table 2. Fluorocarbon powder coating film performance test result table of embodiment 2

[0038]

[0039] The powder coating is applied to the metal surface with an electrostatic spray gun, and baked at 240°C for 10 minutes. The resulting coating has undergone a salt spray test (JIS K5400-9.1) for 5,000 hours, and has no adverse reaction to 10% hydrochlo...

Embodiment 3

[0041] Add 80 kg of PVDF resin, 8 kg of epoxy resin E20; 8 kg of acrylic resin; 20 kg of cobalt green; 1 kg of benzoin; 2 kg of BD-3232 leveling agent; German BYK-4510 adhesion promoter 2 Kg; 1 kg of metafluoride rubber and 3 kg of boric acid. The raw materials are melted and mixed at about 100°C, then pressed into tablets, and then crushed into particles with a diameter of 0.5-1cm. Get particles with a particle size of 15-20 μm to get the finished PVDF fluorocarbon powder coating. The performance test is shown in Table 3:

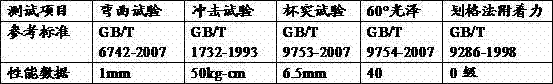

[0042] Table 3. Fluorocarbon powder coating film performance test result table of embodiment 3

[0043]

[0044] The powder coating is applied to the metal surface with an electrostatic spray gun, and baked at 240°C for 10 minutes. The resulting coating has undergone a salt spray test (JIS K5400-9.1) for 5,000 hours, and has no adverse reaction to 10% hydrochloric acid for 20 minutes.

[0045] The raw materials used in the present invention, unless oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com