Preparation method of immobilized enzyme and application of immobilized enzyme in geniposide conversion

A technology of immobilized enzymes and geniposide, applied in the direction of immobilization on/in organic carriers, fermentation, etc., can solve the problems of entering the transformation system and final product safety risks, poor biocompatibility, etc., and achieve enhanced stability Sex and service life, increase resistance, increase mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of immobilized enzyme beads

[0038]Prepare 100mL of 2% sodium alginate solution and 1000mL of 1% CaCl 2 Solution, prepare 4 types of immobilized particles as follows.

[0039] Bead 1: the above sodium alginate solution was added dropwise to CaCl 2 solution, and gently stirred to form calcium alginate gel pellets, which were hardened for 12 hours and washed twice with Buffer B for later use.

[0040] Bead 2: Take 20mL of the above sodium alginate solution and add 50-125mg of genipin, stir and cross-link for 5-8 hours, then add CaCl drop by drop 2 The solution is formed into a ball, and the subsequent steps are the same as the ball 1.

[0041] Bead 3: Take 80mL of the above-mentioned sodium alginate solution and add 200-500mg of genipin, stir and cross-link for 2-4 hours, then add 5-8mL of the above-prepared β-glucosidase enzyme solution, stir and cross-link for 3-5 hours , followed by dropwise addition of CaCl 2 The solution is formed into a ball, and t...

Embodiment 2

[0045] Investigate the conversion effect of immobilized β-glucosidase prepared by different methods

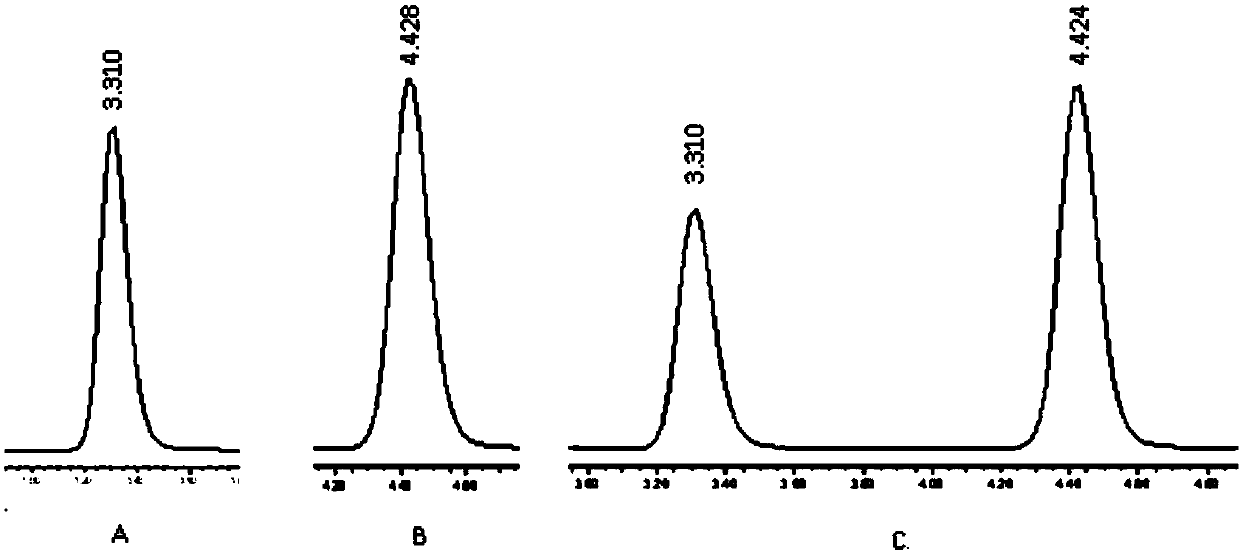

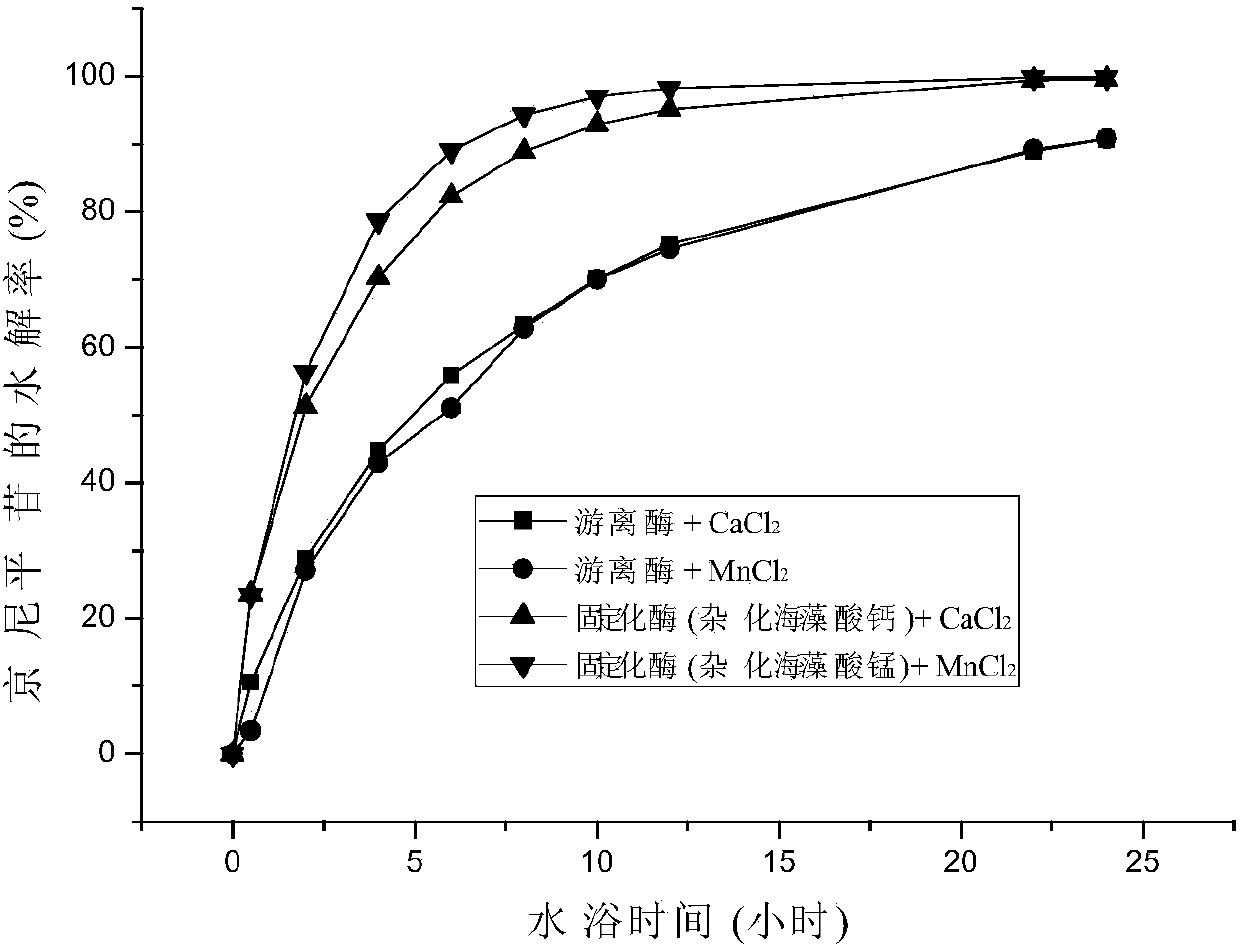

[0046] According to the above enzyme activity assay method, the enzyme activities of the hybrid calcium alginate-immobilized enzyme (bead 3) and hybrid manganese alginate-immobilized enzyme (bead 4) prepared above were determined to be 3.1 and 5.7 U / ml respectively. glue. Take the immobilized enzyme and the free enzyme with the same enzyme activity (34U) to carry out the conversion experiment, wherein the two immobilized beads take the same volume. The transformation system is: the substrate is 1% geniposide (dissolved in Buffer B); CaCl is added according to different situations 2 or MnCl 2 solution, CaCl 2 or MnCl 2 The concentration in the system reaches 0.1%; put 40mL of conversion solution into a 150mL Erlenmeyer flask, shake in a water bath, and the temperature is 40°C. figure 1 , taking samples regularly to determine the content of geniposide and genipin, and calcu...

Embodiment 3

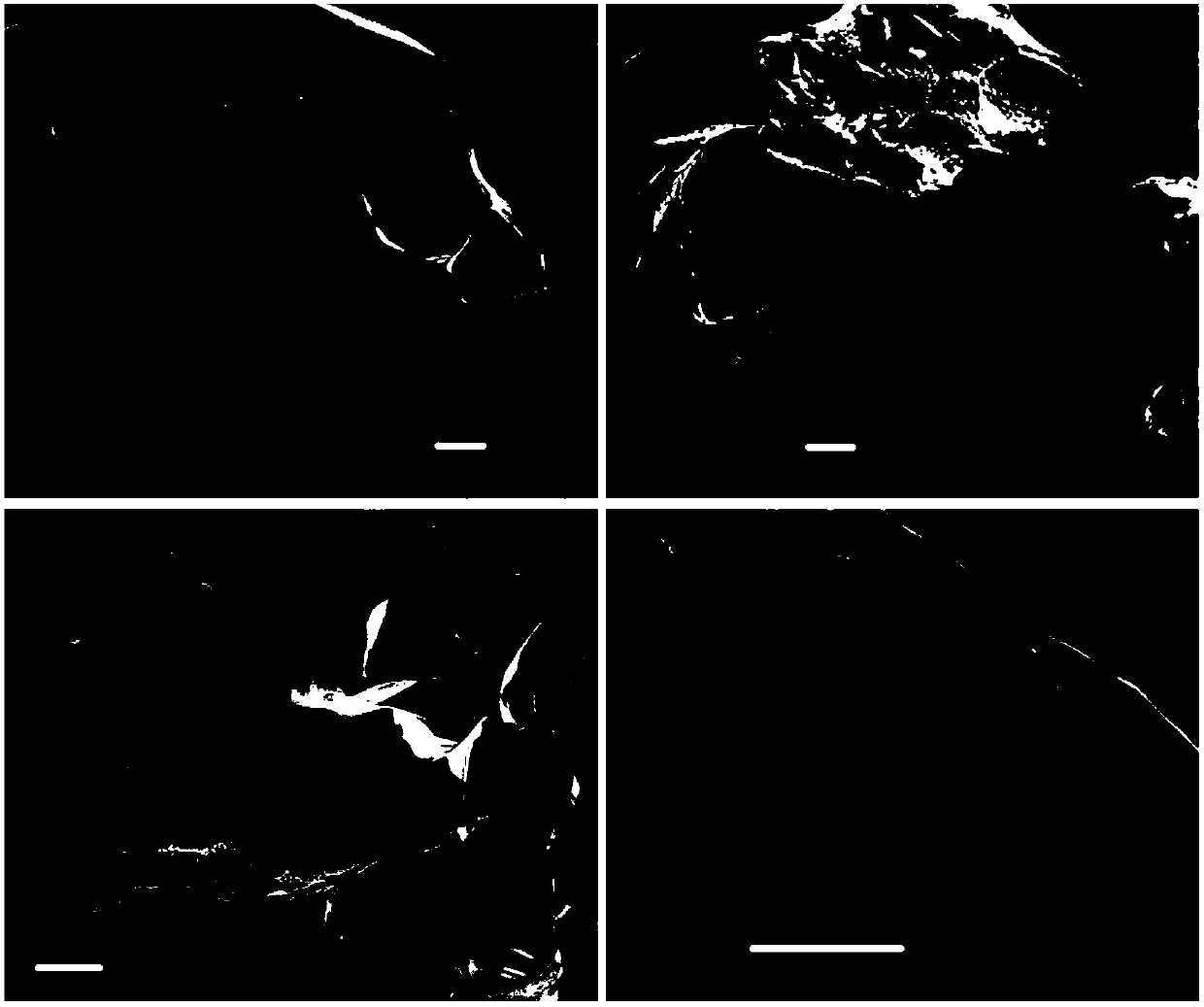

[0048] SEM image analysis of immobilized pellets

[0049] The SEM images of the internal microstructure of different immobilized beads are shown in image 3 shown. With the addition of the cross-linking agent genipin and β-glucosidase enzyme solution, the internal structure of the beads 1 to 4 showed a trend of becoming more and more complex, which endowed them with better and better mechanical strength, and good mechanical strength Strength helps increase resistance to physical damage like agitation. And with Mn 2+ Replacement of Ca in calcium alginate gel 2+ , can resist the cleavage of the gel by phosphate in the enzyme solution or in the conversion system, and enhance the service life of the conversion enzyme.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com