Extinction translucent blue electrophoresis aluminium profile and preparation method thereof

An aluminum profile, translucent technology, applied in the field of aluminum profiles, can solve the problems of serious light pollution, insufficient variety of colors, and affecting the comfort of life, etc., to achieve the effect of improving color rendering, rich appearance, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

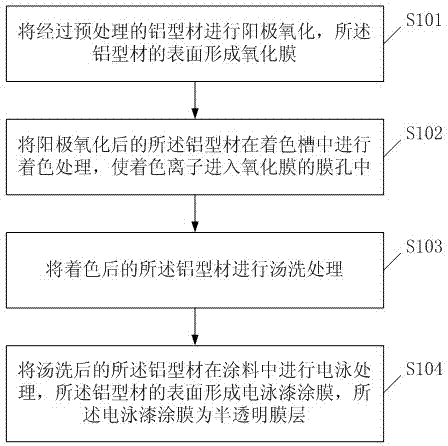

[0054] see figure 1 , the invention provides a method for preparing a matte translucent blue electrophoretic aluminum profile, comprising the following steps:

[0055] S101, performing anodic oxidation on the pretreated aluminum profile, forming an oxide film on the surface of the aluminum profile.

[0056] S102, performing coloring treatment on the anodized aluminum profile in a coloring tank, so that coloring ions enter into pores of the oxide film.

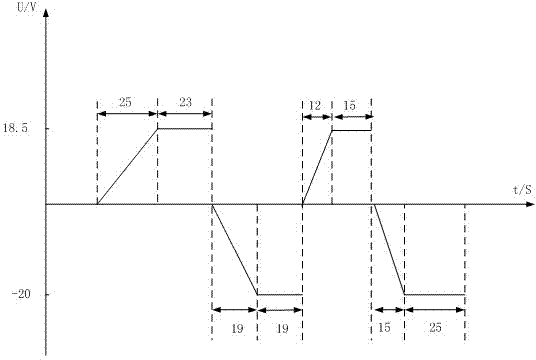

[0057] The colored bath liquid is composed of nickel sulfate and boric acid, wherein the concentration of nickel sulfate is 140-150 g / L, and the concentration of boric acid is 38-42 g / L. The voltage of the coloring tank is 17-21V, the temperature is 24-26°C, the pH of the tank solution is 3.8-4.5, and the aluminum ion is controlled below 100ppm. Moreover, the coloring process uses a polarity inversion rectifier to exchange positive and negative currents, so that nickel ions in the bath solution enter the pores of the oxide fi...

Embodiment 1

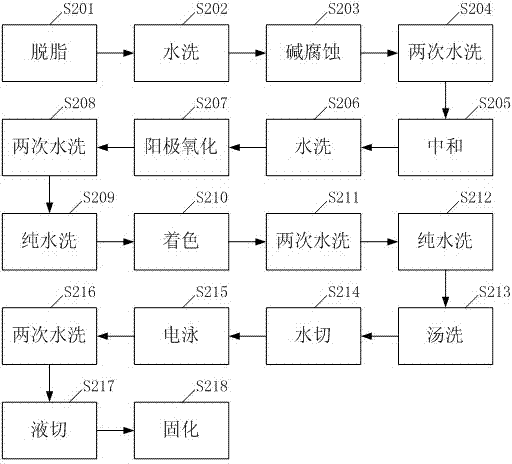

[0160] (1) Degrease the aluminum profile at room temperature, and the degreasing time is 180 s;

[0161] (2) Wash the degreased aluminum profile at room temperature for 60 s;

[0162] (3) Alkali corrosion is carried out on the aluminum profile after washing at 45°C, and the alkali corrosion time is 100 s;

[0163] (4) Wash the aluminum profile after alkali corrosion twice at room temperature, and the washing time for each time is 60 s;

[0164] (5) Neutralize the washed aluminum profile at room temperature, the neutralization time is 180 s, and the neutralization reagent used is pure sulfuric acid solution;

[0165] (6) Wash the neutralized aluminum profile at room temperature for 1 second;

[0166] (7) Wash the aluminum profiles at 19°C with pure H 2 SO 4 Carry out constant voltage anodic oxidation, the surface of the aluminum profile forms an active oxide film, the oxidation time is 30min, and the voltage is 14V;

[0167] (8) Wash the anodized aluminum profile twice at ...

Embodiment 2

[0180] (1) Degrease the aluminum profile at room temperature, and the degreasing time is 240s;

[0181] (2) Wash the degreased aluminum profile at room temperature for 120s;

[0182] (3) Alkali corrosion is carried out on the aluminum profile after washing at 50°C, and the alkali corrosion time is 300 s;

[0183] (4) Wash the aluminum profile after alkali corrosion twice at room temperature, and the time of each washing is 120s;

[0184] (5) Neutralize the washed aluminum profile at room temperature, the neutralization time is 300s, and the neutralization reagent used is pure sulfuric acid solution;

[0185] (6) Wash the neutralized aluminum profile at room temperature for 30 seconds;

[0186] (7) Wash the aluminum profiles at 20°C with pure H 2 SO 4 Carry out constant current anodic oxidation, the surface of the aluminum profile forms an active oxide film, the oxidation time is 40min, and the current density is 120A / M 2 ;

[0187] (8) Wash the anodized aluminum profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com