Measuring method and measuring device of small amount of ammonia in gas

A measuring method and technology of measuring device, which are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problems of sulfuric acid solution damage, complicated analysis, and shortening of service life, etc. Achieve the effect of solving large analysis errors and sufficient absorption and response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

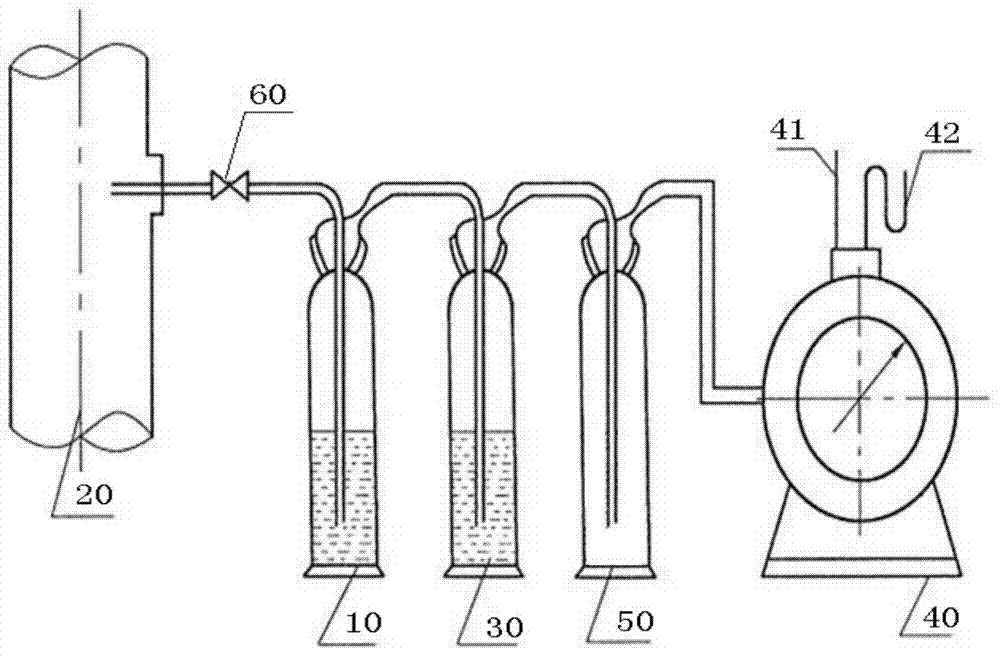

Method used

Image

Examples

Embodiment 1

[0049] Analysis of trace amounts of ammonia in the fresh gas of Davie coal-to-methanol process in the UK:

[0050] (1) Characteristics of syngas

[0051] The main components of syngas are carbon monoxide and hydrogen (accounting for about 97%). The control index of ammonia content in the gas is <100PPm (ammonia in fresh gas<20PPm), and the gas contains trace amounts of hydrogen chloride (about 0.1PPm) and hydrogen sulfide (0.1 around PPM), etc.

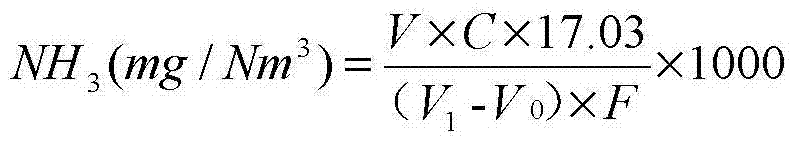

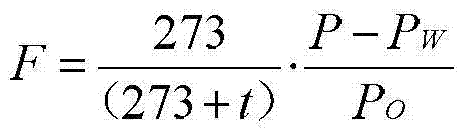

[0052] (2) Method principle

[0053] a The principle of acid-base neutralization reaction, the chemical reaction equation is: 2NH 3 +H 2 SO 4 =(NH 4 ) 2 SO 4

[0054] b Methyl red indicator color change principle.

[0055] The principle that c hydrogen sulfide gas reacts with lead acetate solution to form lead sulfide precipitates and is absorbed. The chemical reaction equation is: Pb(CH 3 COO) 2 +H 2 S=PbS↓+2CH 3 COOH

[0056] d Hydrogen chloride gas reacts with lead acetate solution to generate lead chloride precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com