Imaging modification method for strengthening performance of piezoelectric film sensor

A technology of piezoelectric film and modification method, which is applied in the direction of analyzing fluids by using acoustic waves/ultrasonic waves/infrasonic waves, etc., which can solve the problems of weakening device sensitivity and specificity, increasing quality, etc., and achieve reduction of non-specific adsorption, reduction of influence, and reduction of space position The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

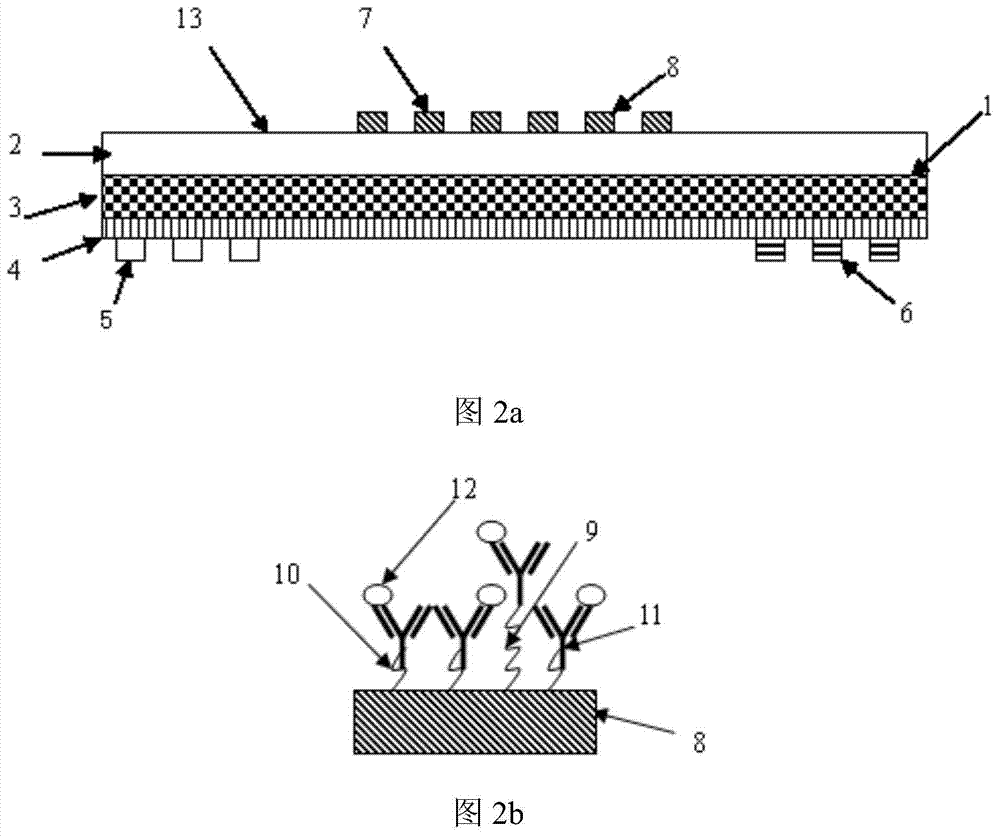

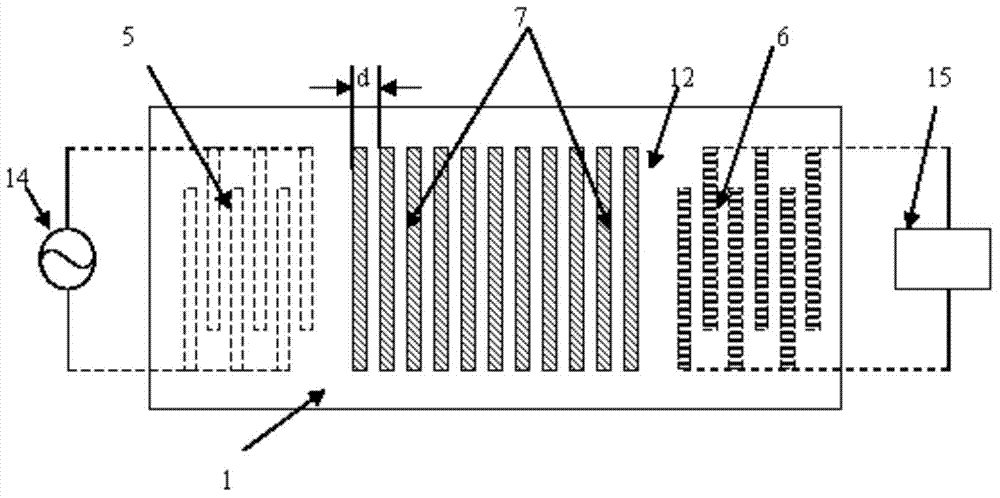

[0049] Such as figure 2 shown. Piezoelectric film sensor 1 is composed of the following parts: silicon film structure 2 is etched out by wet method, ground electrode GND3 and piezoelectric film 4 are placed on the back or front of the film, interdigital transducer (Interdigital transducer, IDT) excitation electrode 5 and receiving electrode 6 Between them is the sound wave transverse propagation area. The electrode spacing is d.

[0050] Such as figure 2 shown. A self-assembled monomolecular film layer 7 is fabricated in the acoustic wave propagation area between the excitation electrode 5 and the receiving electrode 6 . Firstly, metal images 8 with a thickness of 5-20 nm are sputtered and uniformly arranged into strip-shaped regions with a line width and spacing of about 200 μm. Preferably, the wavelength λ of the modulated sound wave is in the range of 10-500 μm, and the spacing of the gold strips is d=λ / n.

[0051] Preferably, 2 to 3 kinds of alkanethiol molecules w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com