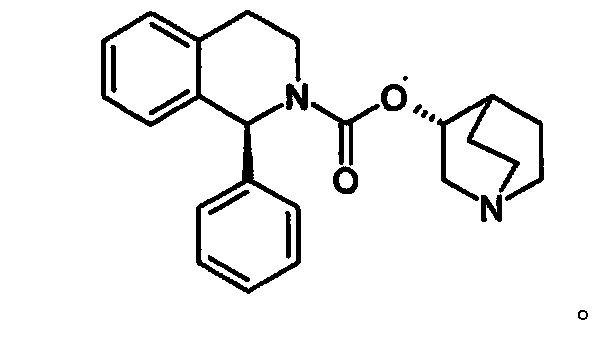

Process for the preparation of solifenacin and salts thereof

A solifenacin and diastereomeric technology, which is applied in the field of preparation of solifenacin and its salts, can solve the problems of expensive and difficult preparation, and achieve the effects of mild conditions, short time and reduced total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

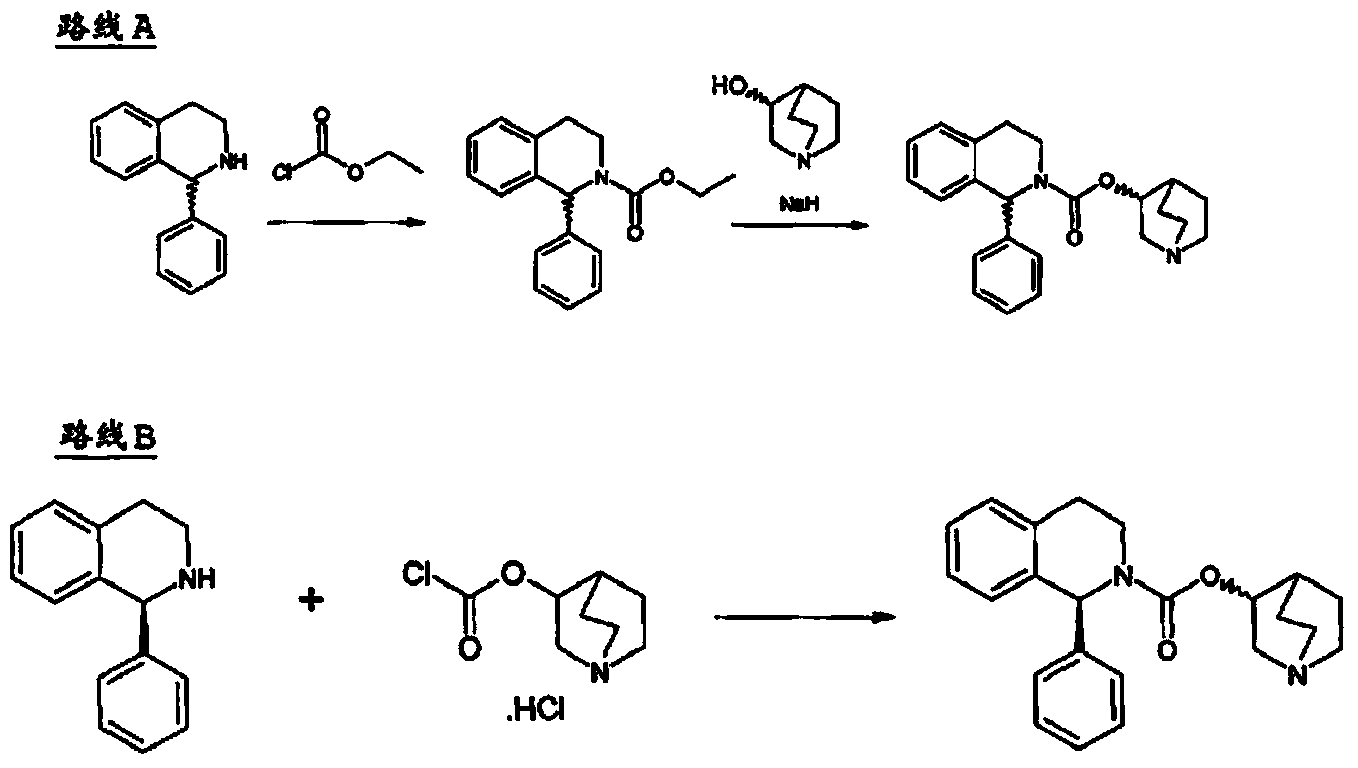

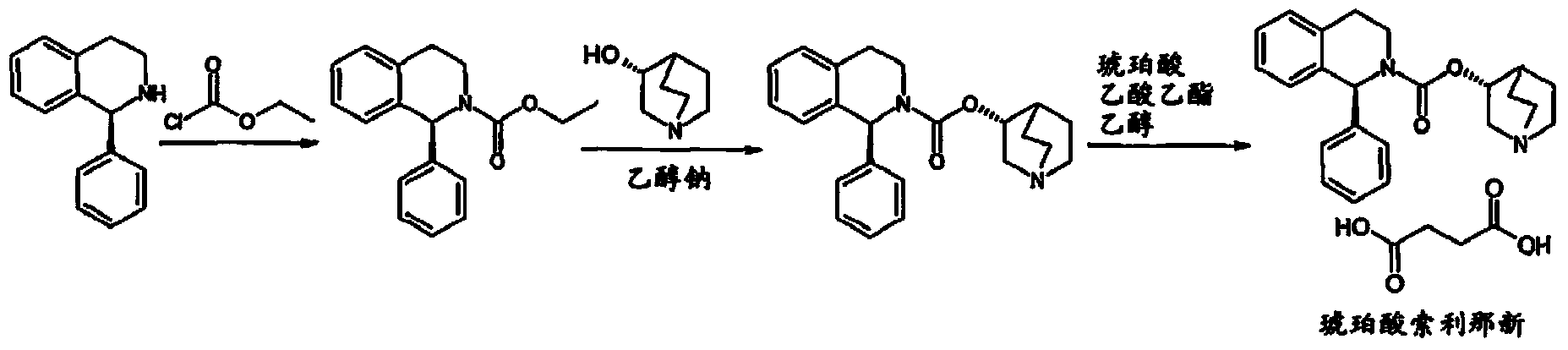

Method used

Image

Examples

Embodiment 1

[0092] Preparation of (R)-quinuclidin-3-yl phenethylcarbamate (Compound III), Method A.

[0093] 14 g (86.17 mmol) 1,1′-carbonyldiimidazole was added to a suspension of 10 g (78.51 mmol) 3(R)-quinine alcohol in 150 mL THF at 0° C. under nitrogen atmosphere. The reaction mixture was left under stirring at 0 °C for 4 h until cleared by TLC (CH 2 Cl 2 :MeOH:NH 3 Aq. 9:1:0.1) Complete conversion to (R)-imidazole-1-carboxylic acid 1-azabicyclo[2.2.2]oct-3-yl ester (Compound Ia) was observed. To the obtained solution was added dropwise a mixture of 9.9 mL (78.51 mmol) of 2-phenethylamine and 10.0 mL (78.51 mmol) of triethylamine at 0°C. After 30 minutes at 0 °C, the reaction mixture was allowed to reach room temperature and left to stir overnight under nitrogen atmosphere. The solvent was distilled off in vacuo and the residue was dissolved in 100 mL of dichloromethane and extracted twice with 50 mL of 1N HCl. The aqueous extract was basified to pH 10 with potassium carbonate...

Embodiment 2

[0096] Preparation of (R)-quinuclidin-3-yl phenethylcarbamate (Compound III), Method B.

[0097] a) Preparation of phenethylurethane (compound IIa).

[0098] At 0° C., 13.9 mL (145 mmol) of ethyl chloroformate was added dropwise to a solution of 14.72 g (145 mmol) of triethylamine and 15.99 g (132 mmol) of 2-phenethylamine in 300 mL of dichloromethane. After stirring the mixture at room temperature for 3 hours, it was washed successively with water, HCl 1M and brine, and evaporated to dryness under reduced pressure. The crude product was obtained as a pale yellow oil (27.77 g) and used in the next step without further purification.

[0099] RMN1H(CDCl3),δ(ppm):1.26(t,3H,CH3);2.84(t,2H,CH2);3.3-3.5(m,2H,CH2-N);4.13(q,2H,CH2-O );4.72(s,1H,NH);7.1-7.4(m,5H,Ar).

[0100] b) Preparation of (R)-quinuclidin-3-yl phenethylcarbamate (compound III).

[0101] To a solution of 1.33 g (7.56 mmol) of crude phenethylurethane in a mixture of 1 mL of DMF and 20 mL of toluene was added 1....

Embodiment 3

[0103] Preparation of (R)-quinuclidin-3-yl phenethylcarbamate (Compound III), Method B.

[0104] a) Preparation of N-phenethyl-1H-imidazole-1-carboxamide (compound lib).

[0105] 5.0 g (30.8 mmol) of 1,1′-carbonyldiimidazole was added to a solution of 3.13 g (25.8 mmol) of 2-phenethylamine in 70 mL of dichloromethane under a nitrogen atmosphere. After stirring the mixture at room temperature for 3.5 hours, 70 mL of water was added. The aqueous layer was separated, the organic layer was washed with 70 mL of water and evaporated to dryness under reduced pressure. 5.11 g (92%) of N-phenethyl-1H-imidazole-1-carboxamide were obtained as a white solid and used in the next step without further purification.

[0106] RMN1H(CDCl3),δ(ppm):3.00(t,2H,CH2Ar);3.72(m,2H,CH2N);6.50(s,1H,NH);7.08(s,imidazole);7.00-7.45(m, 6H,Ar+imidazole);8.28(s,1H,imidazole).

[0107] b) At room temperature, 2.36 g (18.6 mmol) of 3(R)-quinine alcohol was slowly added to a suspension of 0.82 g (20.5 mmol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com