a grease composition

A technology of oil composition and triglyceride, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of unsuitability, increase of use cost, and less resources, and achieve clear layers, high expansion rate, and environmental adaptability low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] Embodiment 1, raw material preparation

[0159] 1.1. Fractionation of lard

[0160] Using solvent fractionation method to process lard to obtain fractionated lard, the specific process is as follows:

[0161] 1) Add oil to acetone in a ratio of 1:1, and mix well.

[0162] 2) Cultivate crystals at 6.8°C for 12 hours to form a mixture of solid fat and liquid oil.

[0163] 3) Separating the solid fat and liquid oil by pressure filtration, and taking the liquid oil as raw material for the next fractional extraction.

[0164] 4) Crystal growth at -8°C for 12 hours to form a mixture of solid fat and liquid oil.

[0165] 5) Separating the solid fat and liquid oil by pressure filtration, and taking the solid fat as raw material for the next fractionation.

[0166] 6) Add acetone to the oil according to the ratio of oil: acetone = 1:4, and mix well.

[0167] 7) Crystal growth at -15°C for 12 hours to form a mixture of solid fat and liquid oil.

[0168] 8) Separating the so...

Embodiment 2

[0184] Embodiment 2, oil composition preparation

[0185] According to the ratio in Table 1, the fractionated lard, fractionated palm olein and extremely hydrogenated palm oil were mixed to prepare the oil composition 1-3, and then the oil composition 1-3 was subjected to oil melting, rapid cooling, kneading, The corresponding margarine can be obtained through maturing treatment, wherein the processes of melting oil, quenching and kneading can all be carried out in cream automation equipment, and the specific process is as follows:

[0186] Melting oil step: heating the oil to 60-65 degrees to melt all the oil and obtain an oil mixture.

[0187] Quenching step: put the oil mixture obtained in the oil melting step into a 1-liter stainless steel material tank with an initial temperature of 40-60°C, and cool down at a rate of 5-10°C / min for 1-5 minutes to obtain the quenched material;

[0188] Kneading step: send the rapidly cooled material into the kneading unit, and knead for ...

Embodiment 3

[0205] Embodiment 3, performance detection

[0206] 3.1. Cold resistance test

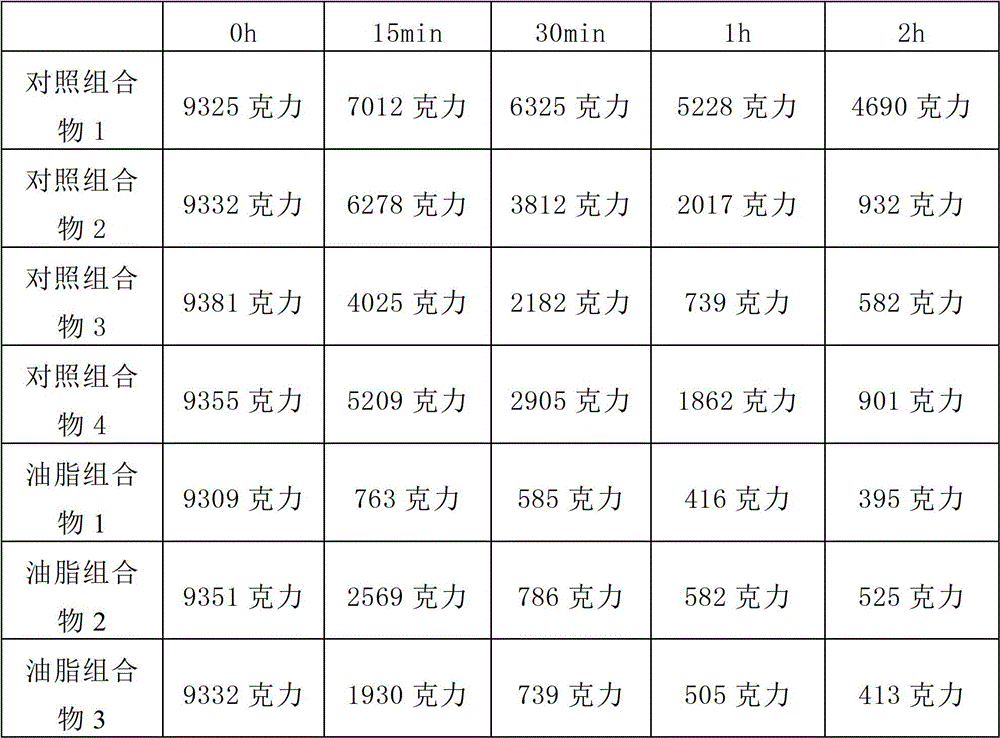

[0207] Take 120g each of the oil composition and the control composition, place them at -25°C for 1 day, then place them in an environment at 0°C, and use a physical property tester to detect their hardness every 1h, so as to test the cold resistance and determine the recovery time. Warm softening time. The test results are shown in Table 4:

[0208] Table 4, the hardness test results of the oil composition and the control composition at 0-2h

[0209]

[0210] Data analysis: For plastic oil products, it is generally believed that the hardness of 100-800 grams force is a better range of plasticity. It takes more than 1 hour for the control group 1-4 to reach the best plasticity, especially the compound of the control group 1, after being placed for 2 hours, still cannot return to the appropriate plasticity, while the oil composition 1-3 all recovered to a relatively good plasticity within 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com