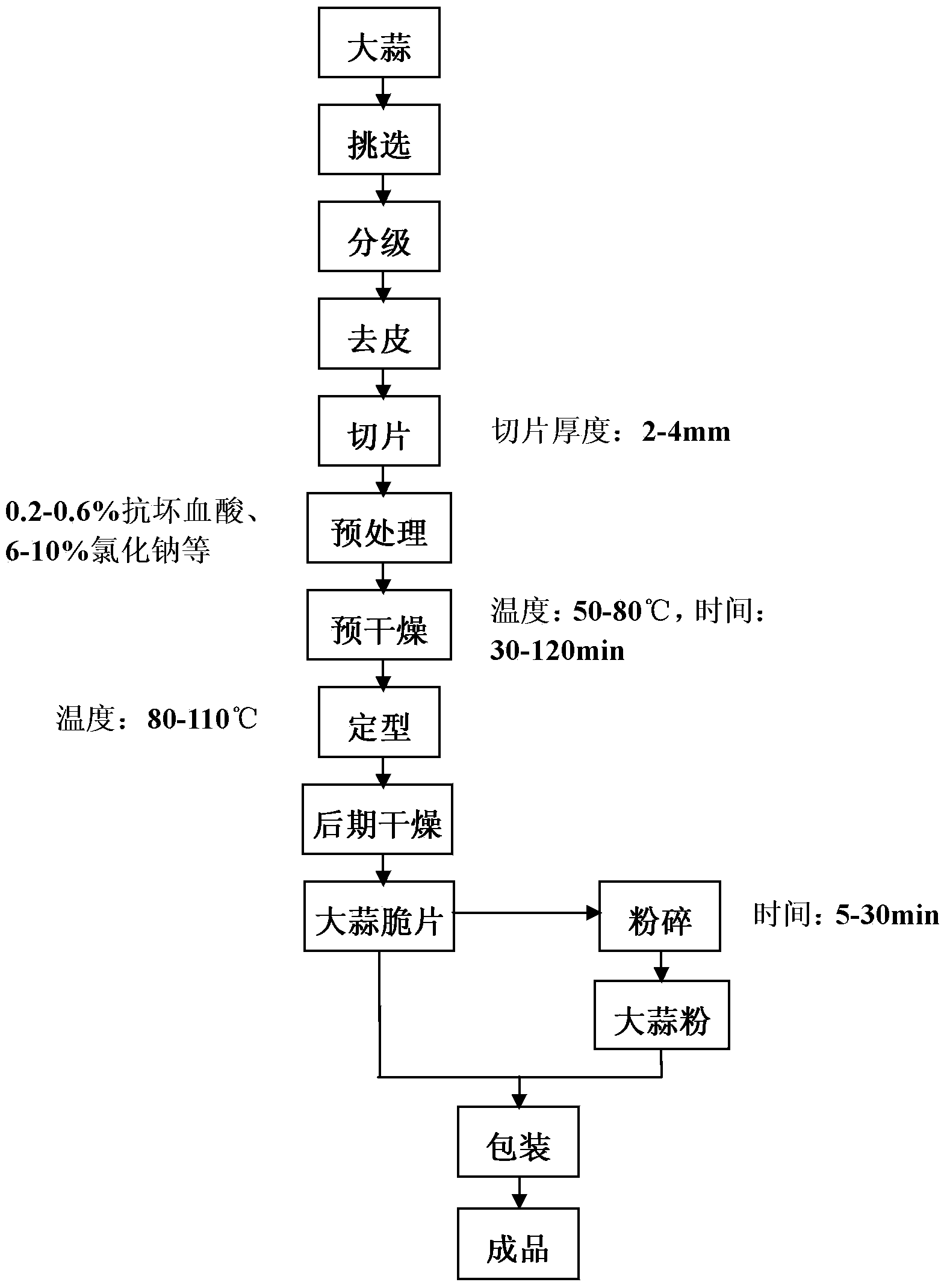

Garlic crisp chips and processing method thereof

The technology of garlic chips and garlic chips is applied in the field of garlic chips and their processing, which can solve the problems of large loss of garlic nutrients, long drying time and high production cost, and achieve good market prospects, low cost and bright color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Selection: Remove defective, moth-eaten, and rotten garlic heads, and select complete, similar-shaped, and similarly-sized garlic heads as raw materials for processing.

[0048] (2) Grading: Separate the garlic heads into cloves, and select garlic cloves with similar shapes and sizes.

[0049] (3) Peeling: Peel the garlic cloves carefully to ensure that the surface of the garlic cloves is not damaged, wash the surface of the garlic cloves with clean water, and drain.

[0050] (4) Slicing: Cut the garlic cloves lengthwise into 2-4mm (eg 3mm) garlic slices.

[0051](5) Pretreatment: Soak garlic slices in 10% sodium chloride aqueous solution for 30 minutes, then wash them with running water, and then soak them in 0.6% ascorbic acid aqueous solution for 30 minutes to To achieve the purpose of seasoning and color protection, and finally wash with tap water;

[0052] (6) Pre-drying: put the garlic slices obtained in step (5) into hot air drying equipment for pre-drying,...

Embodiment 2

[0065] (1) Selection: Remove defective, moth-eaten, and rotten garlic heads, and select complete, similar-shaped, and similarly-sized garlic heads as raw materials for processing.

[0066] (2) Grading: Separate the garlic heads into cloves, and select garlic cloves with similar shapes and sizes.

[0067] (3) Peeling: Peel the garlic cloves carefully to ensure that the surface of the garlic cloves is not damaged, wash the surface of the garlic cloves with clean water, and drain.

[0068] (4) Slicing: Cut the garlic cloves lengthwise into 2-4mm (eg 3mm) garlic slices.

[0069] (5) Pretreatment: Soak garlic slices in 10% sodium chloride aqueous solution by mass for 30 minutes to achieve the purpose of seasoning, then wash them with running water, and then place them in 0.1%, cysteine mass percentage concentration 0.02%, ascorbic acid mass percentage concentration 0.15% and water, soak in the mixed color protection solution for 30min to achieve the purpose of color protection. ...

Embodiment 3

[0081] (1) Selection: Remove defective, moth-eaten, and rotten garlic heads, and select complete, similar-shaped, and similarly-sized garlic heads as raw materials for processing.

[0082] (2) Grading: Separate the garlic heads into cloves, and select garlic cloves with similar shapes and sizes.

[0083] (3) Peeling: Peel the garlic cloves carefully to ensure that the surface of the garlic cloves is not damaged, wash the surface of the garlic cloves with clean water, and drain.

[0084] (4) Slicing: Cut the garlic cloves lengthwise into 2-4mm (eg 3mm) garlic slices.

[0085] (5) Pretreatment: Soak garlic slices in 6% sodium chloride aqueous solution for 30 minutes, then wash them with running water; then soak them in 0.6% ascorbic acid aqueous solution for 30 minutes, then After washing with flowing water, soak in soybean oil for 30 minutes to achieve seasoning and color protection, and then wash with tap water;

[0086] (6) Pre-drying: put the garlic slices obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com