Improved method of bone strengthening injection production process

A production process and injection technology, applied in the field of medicine, can solve the problems of incomplete extraction of active ingredients, long extraction time, unfavorable human body, etc., and achieve the effects of improving the extraction rate and the utilization rate of raw materials, shortening the extraction time and human body safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

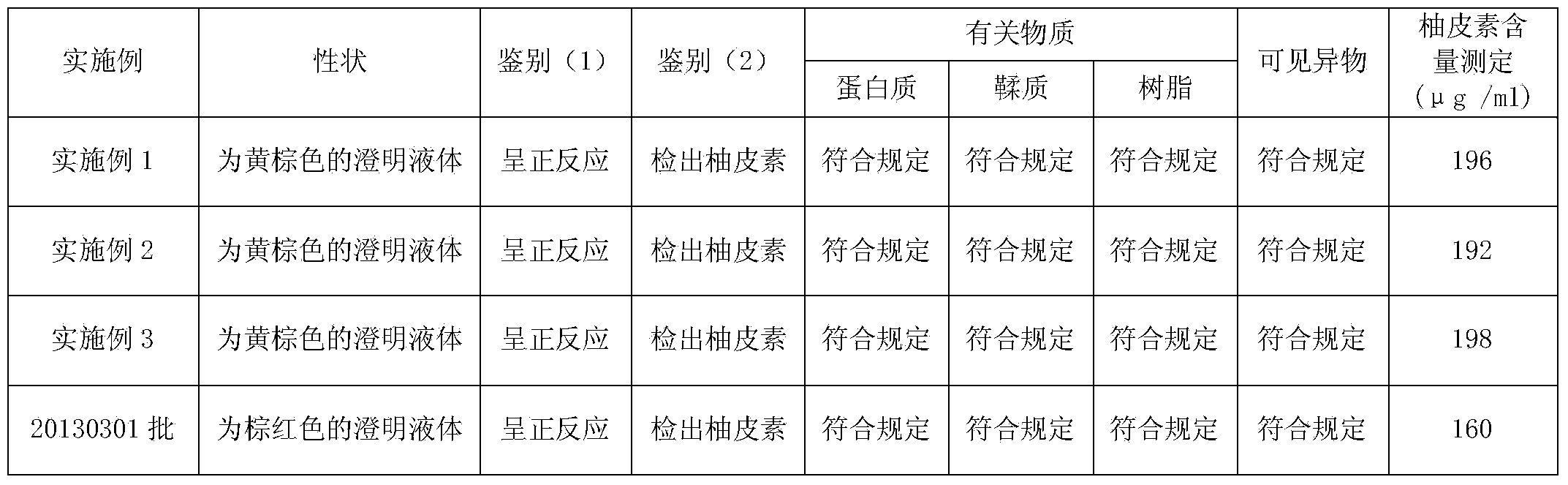

Embodiment 1

[0019] An improved method for the production process of Jiangu injection, comprising the following steps:

[0020] 1. Take 2500g of Zhagu medicinal material, wash, dry, crush, and pass through a 40-mesh sieve to obtain Zangu medicinal material powder;

[0021] 2. Put the war bone medicinal material powder into the ultrasonic extraction tank, add 6 times the amount of 40% ethanol for ultrasonic vibration extraction, the time is 40 minutes, the oscillation frequency is 50kHz, the temperature is controlled at room temperature, extracted 3 times, filtered, combined extraction Liquid, get the raw liquid of war bone medicinal material;

[0022] 3. The stock solution of warbone medicinal materials is recovered under reduced pressure below 60°C to ethanol, concentrated to a clear paste with a relative density of 1.15 (50°C), passed through a D101 macroporous adsorption resin column (the ratio of medicinal materials to resin is 1:2), and water Elute until the eluent is colorless, then...

Embodiment 2

[0025] An improved method for the production process of Jiangu injection, comprising the following steps:

[0026] 1. Take 2500g of the war bone medicinal material, wash, dry, crush, and pass through a 50-mesh sieve to obtain the war bone medicinal material powder;

[0027] 2. Put the war bone medicinal material powder into the ultrasonic extraction tank, add 8 times the amount of 40% ethanol for ultrasonic vibration extraction, the time is 20 minutes, the oscillation frequency is 100kHz, the temperature is controlled at room temperature, extracted twice, filtered, combined extraction Liquid, get the raw liquid of war bone medicinal material;

[0028] 3. The stock solution of warbone medicinal material is recovered under reduced pressure below 60°C to ethanol, concentrated to a clear paste with a relative density of 1.20 (50°C), passed through a D101 macroporous adsorption resin column (the ratio of medicinal material to resin is 1:3), and water Elute until the eluent is colo...

Embodiment 3

[0031] An improved method for the production process of Jiangu injection, comprising the following steps:

[0032] 1. Take 2500g of the war bone medicinal material, wash, dry, crush, and pass through a 50-mesh sieve to obtain the war bone medicinal material powder;

[0033] 2. Put the war bone medicinal material powder into the ultrasonic extraction tank, add 7 times the amount of 40% ethanol for ultrasonic vibration extraction, the time is 30 minutes, the oscillation frequency is 80kHz, the temperature is controlled at room temperature, extracted 3 times, filtered, combined extraction Liquid, get the raw liquid of war bone medicinal material;

[0034] 3. The stock solution of warbone medicinal material is recovered under reduced pressure below 60°C to ethanol, concentrated to a clear paste with a relative density of 1.18 (50°C), passed through a D101 macroporous adsorption resin column (the ratio of medicinal material to resin is 1:3), and water Elute until the eluent is col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com