A dynamic gas distribution system for simulating ship exhaust

A ship exhaust and dynamic gas distribution technology, which is applied in the direction of gas and gas/steam mixing, fluid mixer, mixer accessories, etc., can solve the problem of inability to provide large flow continuously for a long time, poor anti-corrosion performance of equipment, and insufficient pertinence and other issues, to achieve the effect of flexibility, good air tightness and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

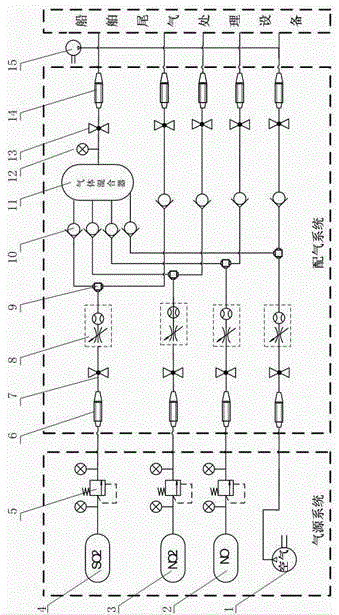

[0030] Such as figure 1 As shown, the dynamic air distribution system for simulating ship exhaust provided by the present invention includes an air source system and an air distribution system.

[0031] The gas source system includes a high-pressure gas cylinder, an air compressor 1, a pressure reducing valve 5, a pressure gauge 12 and a gas pipeline. Air compressor 1 is the Y2K-1 model produced by Fujian Juba Machinery Co., Ltd. The high-pressure gas cylinder provides high-pressure pure gas, which is 99.9% pure gas provided by Shanghai Maxtor Special Gas Co., Ltd.

[0032] The gas distribution system includes an inlet port 6, an inlet ball valve 7, a flow meter 8, a three-way ferrule joint 9, a check valve 10, a gas mixer 11, an outlet ball valve 13, an outlet port 14, a pressure gauge 12 and a gas pipeline. Both the inlet interface and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com