Sunlight responding nano hetero-structure photocatalyst and preparation method thereof

A nano-heterostructure, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low photocatalytic efficiency and achieve improved Solar photocatalytic efficiency, broadening the photoresponse range, and the effect of enhanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

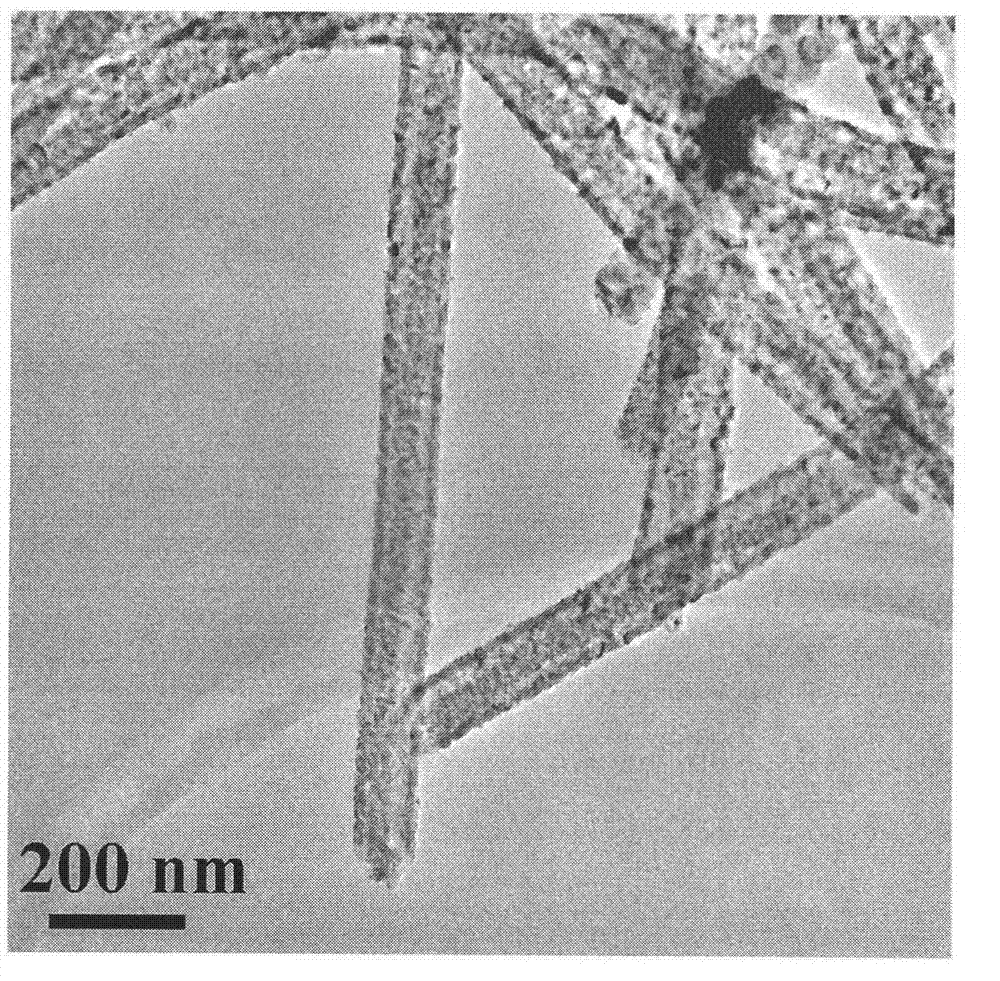

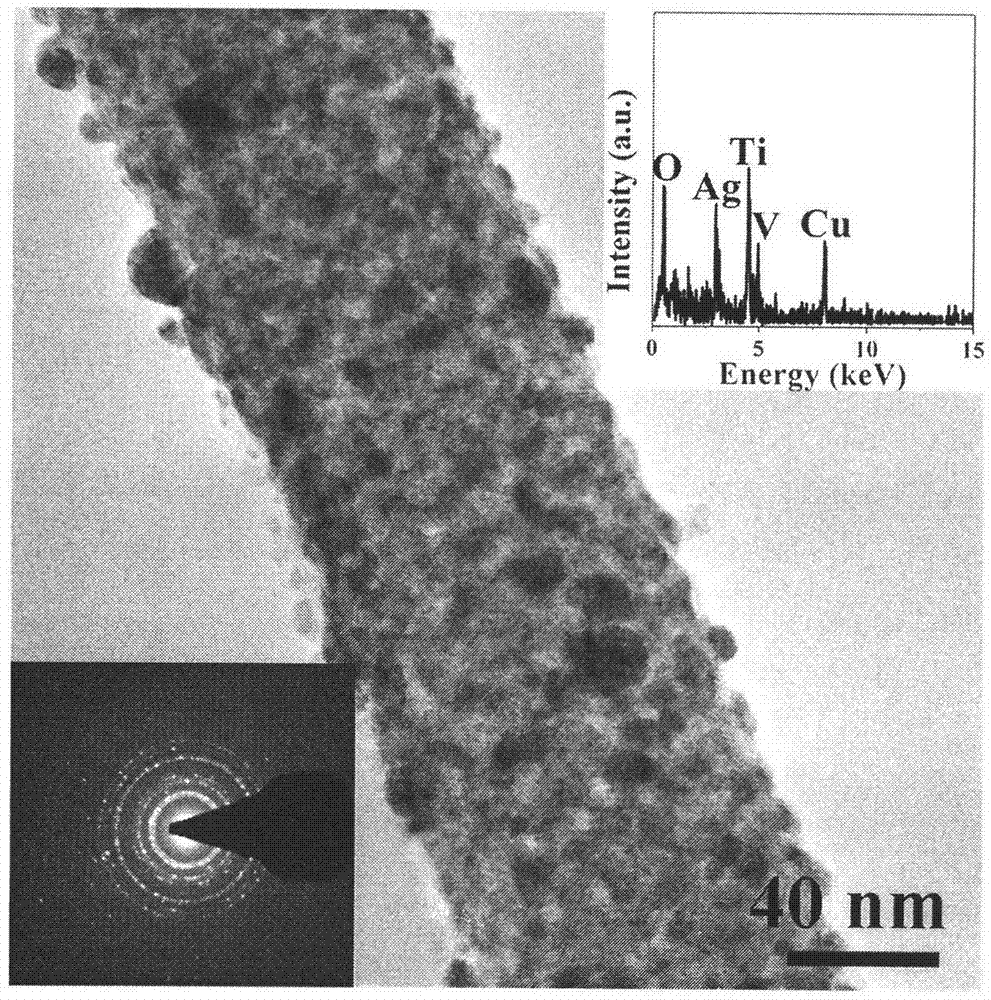

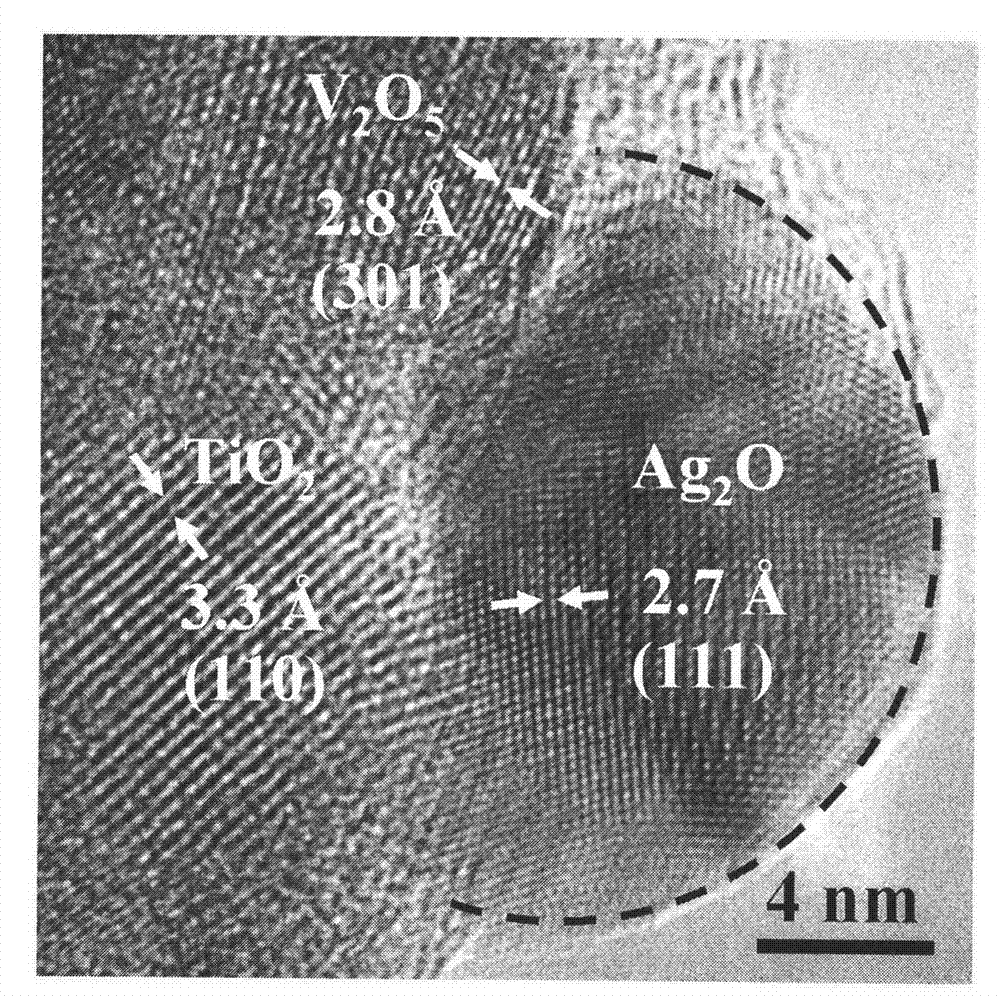

[0039] TiO 2 / V 2 o 5 Preparation of nanofibers: Mix 0.5g tetrabutyl titanate, 0.2g polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 0.75g absolute ethanol, 0.45g dimethylacetamide (DMAC) and 1.25g glacial acetic acid And fully stirred for 20 minutes to obtain a uniform PVP / titanate solution, which was recorded as solution A; then 1.2g of polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 0.4g of vanadyl diacetylacetonate (VO(acac) 2 ) and 7.0g dimethylacetamide (DMAC) were mixed and fully stirred for 20min, which was recorded as solution B; finally, solution A and solution B were mixed and fully stirred for 1h to obtain a uniform PVP / titanate / VO(acac ) 2 A mixed solution in which the Ti / V atomic ratio is 1:1; viscous PVP / titanate / VO(acac) 2 The mixed solution is spun to obtain nanofibers. The specific parameters of electrospinning are as follows: the inner diameter of the electrospinning needle is 0.4mm, the distance between the bottom of the nee...

Embodiment 2

[0043] TiO 2 / V 2 o 5 Preparation of nanofibers: 1.0g tetrabutyl titanate, 0.4g polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 1.5g absolute ethanol, 0.9g dimethylacetamide (DMAC) and 2.5g glacial acetic acid were mixed And fully stirred for 20 minutes to obtain a uniformly mixed PVP / titanate solution, which was recorded as solution A; then 1.2g of polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 0.4g of vanadyl diacetylacetonate (VO(acac) 2 ) and 7.0g dimethylacetamide (DMAC) were mixed and fully stirred for 20min, which was recorded as solution B; finally, solution A and solution B were mixed and fully stirred for 1h to obtain a uniform PVP / titanate / VO(acac ) 2 A mixed solution in which the Ti / V atomic ratio is 2:1; the viscous PVP / titanate / VO(acac) 2 The mixed solution is spun to obtain nanofibers. The specific parameters of electrospinning are as follows: the inner diameter of the electrospinning needle is 0.4mm, the distance between the b...

Embodiment 3

[0047] TiO 2 / V 2 o 5 Preparation of nanofibers: 2.0g tetrabutyl titanate, 0.8g polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 3.0g absolute ethanol, 1.8g dimethylacetamide (DMAC) and 5.0g glacial acetic acid were mixed And fully stirred for 20 minutes to obtain a uniformly mixed PVP / titanate solution, which was recorded as solution A; then 1.2g of polyvinylpyrrolidone (PVP, average molecular weight: 1300000), 0.4g of vanadyl diacetylacetonate (VO(acac) 2 ) and 7.0g of dimethylacetamide (DMAC) were mixed and fully stirred for 20 minutes, which was recorded as solution B; mixed with solution A and solution B and fully stirred for 1 hour, a uniform PVP / titanate / VO(acac) 2 Mixed solution; wherein the Ti / V atomic ratio is 4:1. Viscous PVP / titanate / VO(acac) was synthesized by electrospinning 2 The mixed solution is spun to obtain nanofibers. The specific parameters of electrospinning are as follows: the inner diameter of the electrospinning needle is 0.4mm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com