Method for preparing calcium carbide

A calcium carbide and carbon-based technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of backward production technology, high energy consumption, and thermal efficiency of only 50%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

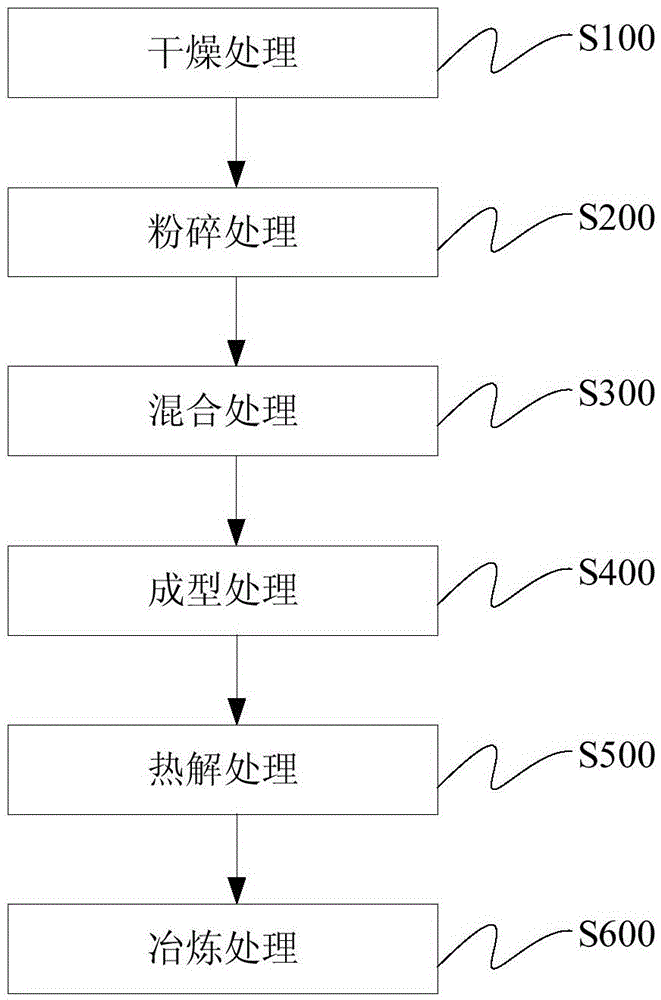

[0023] Thus, in the method for preparing calcium carbide in the embodiment of the present invention, raw coal and quicklime are pulverized into ultrafine powders, and co-pyrolysis is carried out to obtain direct raw material coke, semi-coke or a mixture of carbon black and quicklime for preparing calcium carbide, and further use The direct raw material is hot sent to an electric arc furnace to prepare calcium carbide. Therefore, the method combines the preparation of calcium carbide raw materials with the production of calcium carbide, and the calcium carbide can be directly prepared by using raw coal and quicklime. The limitation of the existing calcium carbide preparation method using coke, semi-coke or carbon black and quicklime as raw materials to prepare calcium carbide is avoided. Moreover, the method for preparing calcium carbide in the above-mentioned embodiments of the present invention pulverizes raw coal and quicklime and then pyrolyzes and smelts, which can signifi...

Embodiment

[0047] raw material:

[0048] Quicklime is used as the calcium-based raw material, and the CaO content is 92%.

[0049] Using lignite as the carbon-based raw material, the main properties of the lignite are shown in Table 1.

[0050] Table 1

[0051] project

unit

value

Remark

[0052] whole water

%

37

received base

%

58

Volatile matter

%

33

5 --> Ash

%

9

[0053] Preparation:

[0054] Firstly, the long-flame coal is dried by an indirect tube-type drum drying device. The drying heat source is 0.8MPa saturated steam, and the moisture content of the lignite after drying is 0.5%.

[0055] After drying, the lignite is pulverized with a ball mill, and the average particle size after pulverization is all less than 10 microns.

[0056] Mix the pulverized ultrafine lignite powder and quicklime (average particle size less than 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com