Cement-stabilized crushed stone for highway pavement base

A technology for cement stabilizing gravel and pavement base, applied in the field of building materials, can solve problems such as unsatisfactory crack resistance, achieve sufficient strength and wear resistance, improve flexural strength, and be cheap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

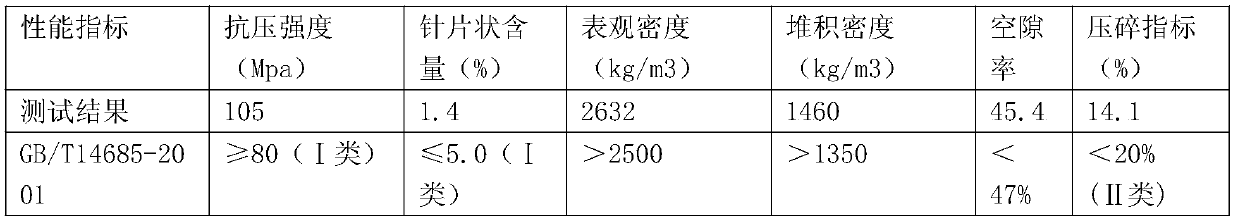

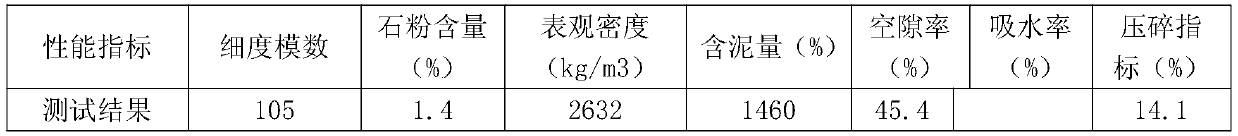

Image

Examples

Embodiment 1

[0064] A pavement base cement-stabilized macadam with high-carbon ferrochrome slag as aggregate, which is made by stirring and mixing P.O.32.5 cement, high-carbon ferrochrome slag aggregate and water, wherein the mass percentage of cement is 4.5%, water The mass percentage is 5.5%, and the rest is high-carbon ferrochrome alloy slag aggregate. P.O.32.5 refers to ordinary Portland cement. The compressive strength of the cement test block after curing for 28 days is 32.5MPa; it has high early strength, high heat of hydration, good frost resistance, poor heat resistance, poor corrosion resistance, and dry shrinkage. smaller.

[0065] The preparation of high-carbon ferrochrome slag aggregates, using high-carbon ferrochrome slag as raw material, can produce coarse aggregate through impact crusher, impact crusher or cone crusher, and part of the coarse aggregate is further crushed into fine aggregate, high carbon The gradation range of ferrochrome alloy slag aggregate after sieving ...

Embodiment 2

[0067] A pavement base cement-stabilized macadam with high-carbon ferrochrome slag as aggregate is prepared by stirring and mixing P.O.42.5 cement, high-carbon ferrochrome slag aggregate and water, wherein the amount of cement is 5% by mass. The grading range of the high-carbon ferrochrome alloy slag aggregate after screening is the same as Table 4.

Embodiment 3

[0069] A pavement base cement-stabilized macadam with high-carbon ferrochrome slag as aggregate is prepared by stirring and mixing P.O.52.5 cement, high-carbon ferrochrome slag aggregate and water, wherein the amount of cement is 5.5% by mass. The grading range of the high-carbon ferrochrome alloy slag aggregates used after screening is the same as Table 4.

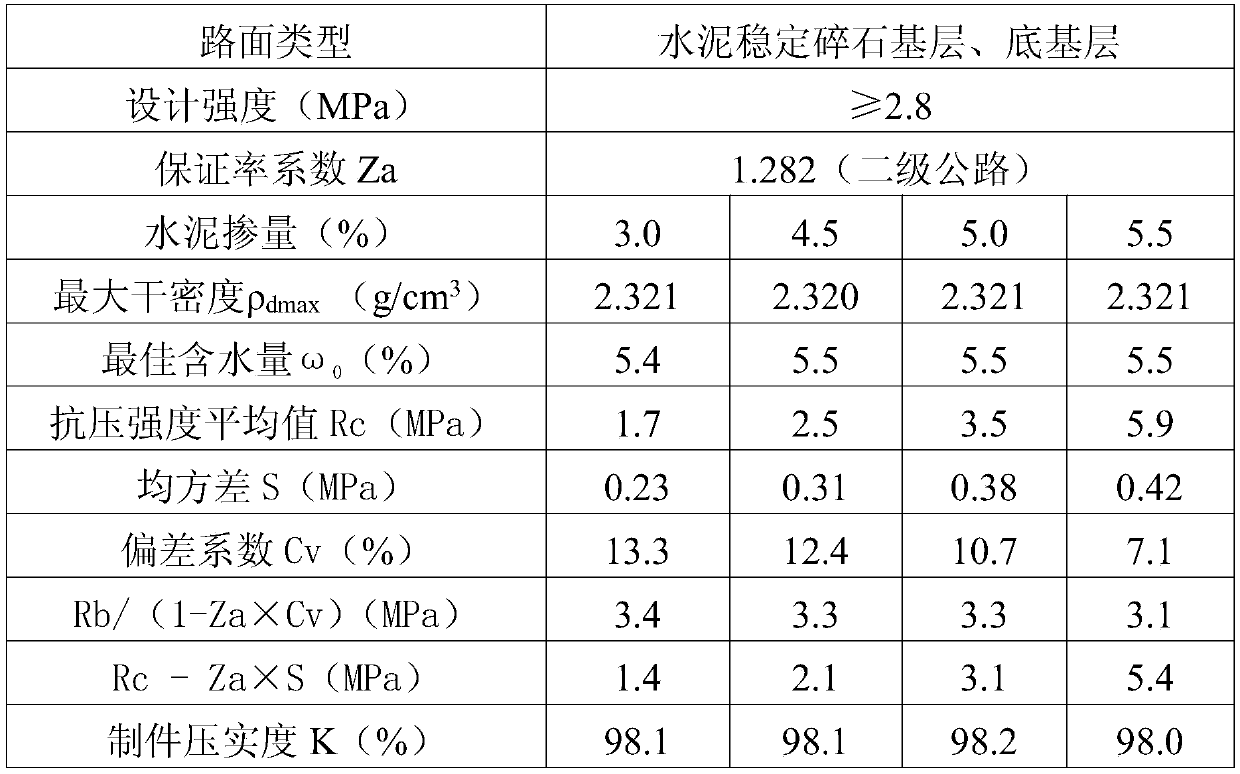

[0070] Finally, a pavement base cement-stabilized macadam prepared with high-carbon ferrochrome slag as aggregate is controlled according to Table 6 for its dry density, optimum water content, and compaction under ambient temperature conditions.

[0071] Table 6 The main control index of cement-stabilized macadam at the pavement base of the present invention

[0072]

[0073] By adjusting the amount of different materials, gradation and mix ratio, the 7-day unconfined compressive strength of the pavement base cement-stabilized gravel using high-carbon ferrochrome slag as aggregates of the present invention is actually ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com