Technique for preparing citric acid by fermenting beta-cyclodextrin mother solution

A technology of cyclodextrin and citric acid, applied in the direction of fermentation, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high energy consumption, energy waste, and high temperature of fermentation liquid, and achieve low energy consumption and high speed , to achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

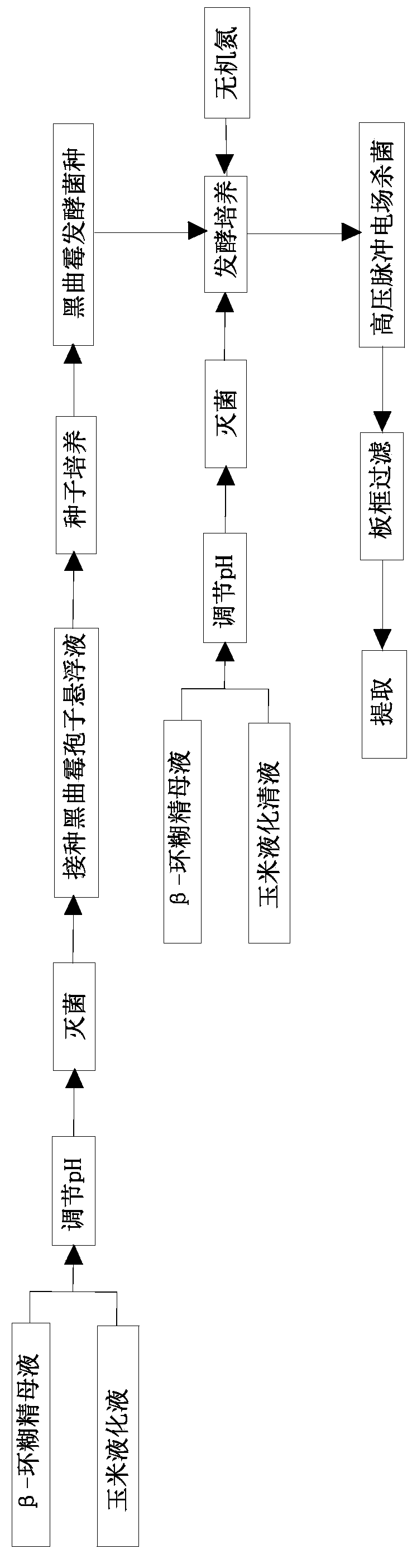

Method used

Image

Examples

Embodiment 1

[0028] Corn is crushed, sieved, pulped, and liquefied by two consecutive steam jets to obtain a corn liquefaction liquid with a total sugar content of 20%, which is subjected to plate and frame filtration to obtain a liquefied clear liquid with a total sugar content of 18%.

[0029] After mixing the β-cyclodextrin mother liquor with a total sugar content of 13% and the corn liquefaction solution at a ratio of 1:2, the total sugar content is 17.7%, measure the carbon-nitrogen ratio, add a small amount of ammonium sulfate, measure its pH, and calculate the added hydrogen The amount of sodium oxide solution, adjust the pH to 6.0, as the seed medium, add it to the citric acid seed culture tank, after high-temperature sterilization, inoculate the Aspergillus niger spore suspension, stir and ventilate, control the temperature at 36 ° C, and cultivate for 20 hours to obtain black Aspergillus fermented strains.

[0030] Mix the β-cyclodextrin crystallization mother liquor with a total...

Embodiment 2

[0034] The corn is crushed, sieved, pulped, sprayed and liquefied to obtain a corn liquefied liquid with a total sugar content of 19%, which is subjected to plate and frame filtration to obtain a liquefied clear liquid with a total sugar content of 17%.

[0035] After mixing the β-cyclodextrin mother liquor with a total sugar content of 14% and the corn liquefaction liquid at a volume ratio of 1:3, the total sugar content is 17.8%, measure the carbon-nitrogen ratio, add a small amount of ammonium nitrate, measure its pH, and calculate the added hydrogen The amount of potassium oxide solution, adjust the pH to 6.5, as the seed medium, add it to the citric acid seed culture tank, after high-temperature sterilization, inoculate the Aspergillus niger spore suspension, stir and ventilate, control the temperature at 34 ° C, and cultivate for 25 hours to obtain black Aspergillus fermented strains.

[0036] Mix the β-cyclodextrin crystallization mother liquor with a total sugar conten...

Embodiment 3

[0040] The corn is crushed, sieved, pulped, and liquefied by two consecutive steam injections to obtain a corn liquefied liquid with a total sugar content of 22%, which is subjected to plate and frame filtration to obtain a liquefied clear liquid with a total sugar content of 20%.

[0041] After mixing the β-cyclodextrin mother liquor with a total sugar content of 14% and the corn liquefaction liquid at a ratio of 1:2, the total sugar content is 19.3%, measure the carbon-nitrogen ratio, add a small amount of ammonium nitrate, measure its pH, and calculate the added hydrogen The amount of potassium oxide solution, adjust the pH to 6.8. As a seed medium, add it to a citric acid seed culture tank, perform high-temperature sterilization, inoculate the Aspergillus niger spore suspension, stir and ventilate, control the temperature at 37° C., and cultivate for 30 hours to obtain Aspergillus niger fermentation strains.

[0042] Mix the β-cyclodextrin crystallization mother liquor with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com