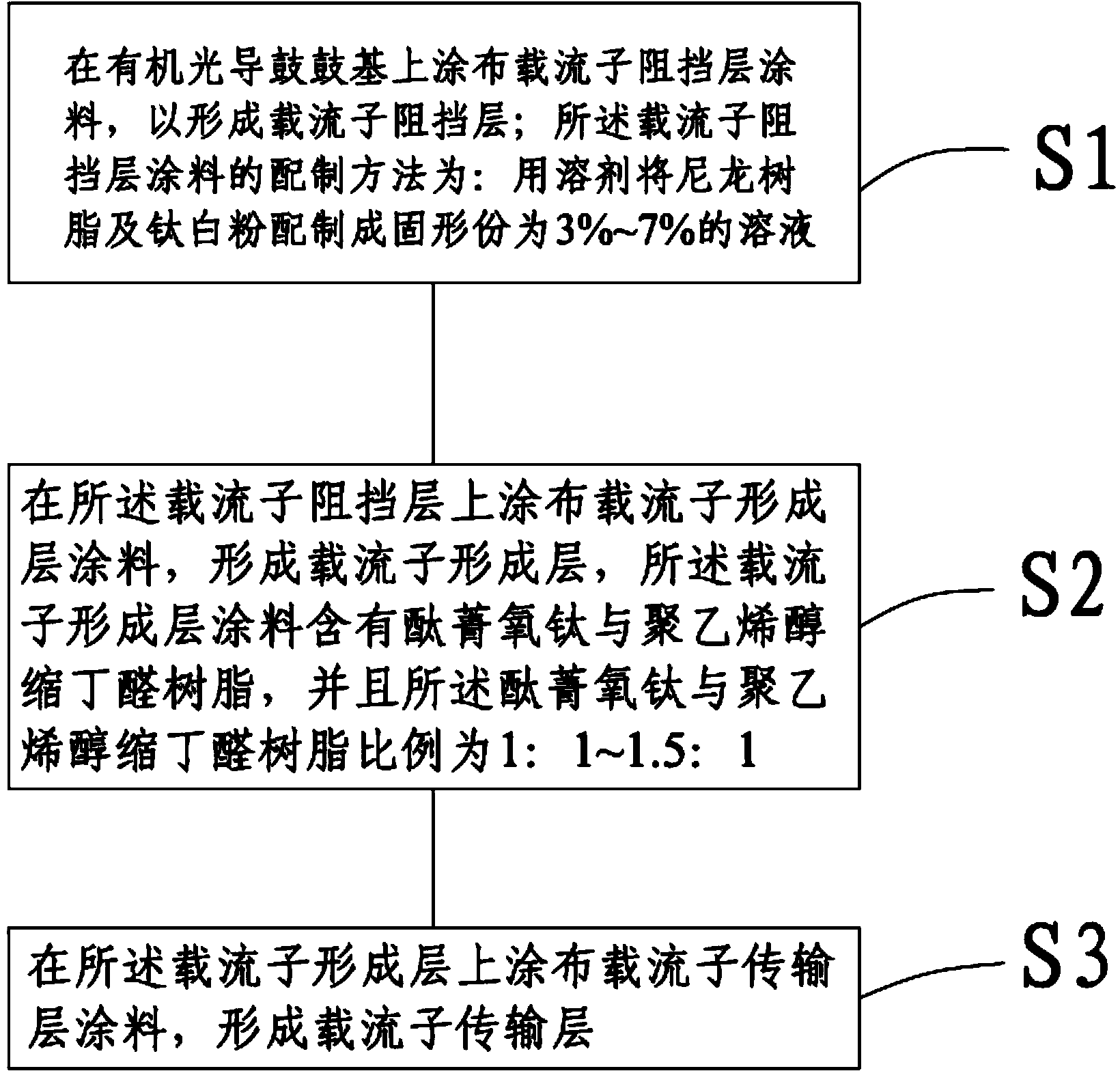

Background-color-free three-layer coating process

A coating process and no background color technology, applied in the field of OPC organic photoconductive drums, can solve the problems of difficult storage, etc., and achieve the effects of easy storage, control of dot rate, and stable coating liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Drum base is mirror anodized drum base

[0061] Step S1, carrier blocking layer paint: nylon resin CM-800078g, titanium dioxide 3.9g, 1600ml methanol, 400ml n-butanol, and prepare a paint with a solid content of about 4.5%. Coating a 0.5 μm thick coating on the mirror anodized drum base forms a carrier blocking layer.

[0062] Step S2, carrier forming layer coating: polyvinyl butyral resin B-90 10.5g, γ-type high-sensitivity titanium phthalocyanine CG-01H 14.8g, tetrahydrofuran 620ml, cyclohexanone 50ml, and the solid content of the preparation is about 4% paint. Coating about 0.5 μm thick coating on the carrier blocking layer forms the carrier forming layer. In the step S2, the drying temperature of the carrier generation layer is 50° C., and the drying time is 30 minutes.

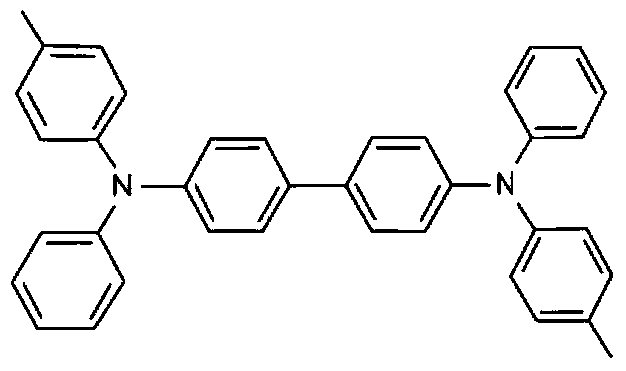

[0063] Step S3, carrier transport layer coating: p-TPD871g, butadiene 871g, bisphenol Z polycarbonate PCX-4002026g, antioxidant BHT76g, high-purity silicone oil 1.8g, dichloromethane 12000ml, 1,...

Embodiment 2

[0068] The second embodiment is basically the same as the first embodiment, except that the drum base is a turning drum base.

[0069] Step S1, carrier blocking layer paint: nylon resin CM-800078g, titanium dioxide 3.9g, 1600ml methanol, 400ml n-butanol, and prepare a paint with a solid content of about 4.5%. Coating a 1μm or 3μm thick coating on the turning drum base forms a carrier blocking layer.

[0070] Step S2, carrier forming layer coating: polyvinyl butyral resin B-90 10.5g, γ-type high-sensitivity titanium phthalocyanine CG-01H 14.8g, tetrahydrofuran 620ml, cyclohexanone 50ml, and the solid content of the preparation is about 4% paint. Coating about 0.3 μm or 0.4 μm thick coating on the carrier blocking layer forms the carrier forming layer. In the step S2, the drying temperature of the carrier generation layer is 60° C., and the drying time is 20 minutes.

[0071] Step S3, carrier transport layer coating: p-TPD871g, butadiene 871g, bisphenol Z polycarbonate PCX-40...

Embodiment 3

[0075] Embodiment 3 is basically the same as Embodiments 1 and 2, except that the drum base is directly anodized with a sand surface, and the step S1 in claim 1 may not be performed if the drum base is anodized with a sand surface, and only the two Floor.

[0076] Step S2, carrier forming layer paint: polyvinyl butyral resin B-9010g, gamma-type high-sensitivity titanium phthalocyanine CG-01H15g, tetrahydrofuran 600ml, cyclohexanone 50ml, made into a paint with a solid content of about 4.1% . Coating about 0.5 μm thick coating on the carrier blocking layer forms the carrier forming layer. In the step S2, the drying temperature of the carrier generating layer is 65° C., and the drying time is 15 minutes.

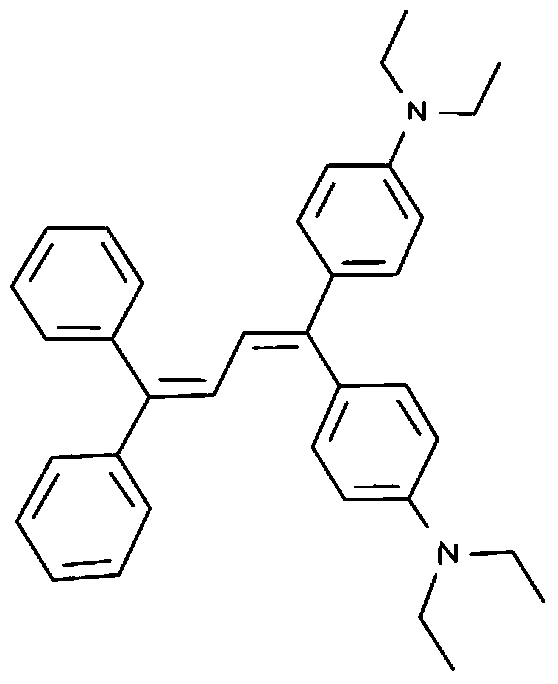

[0077] Step S3, carrier transport layer coating: p-TPD729g, butadiene 912g, bisphenol A and F type copolycarbonate FPC-71552026g, TTA182g, antioxidant BHT73g, high-purity silicone oil 1.73g, dichloromethane 12000ml, 1 , 1500ml of 2-dichloroethane, made into a coating with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com