Lead paste for battery of electric vehicle, and use method thereof

An electric vehicle battery, lead paste technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of long plate curing time, high impurity content, short negative plate life, etc. Easy to mix evenly, reducing the effect of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

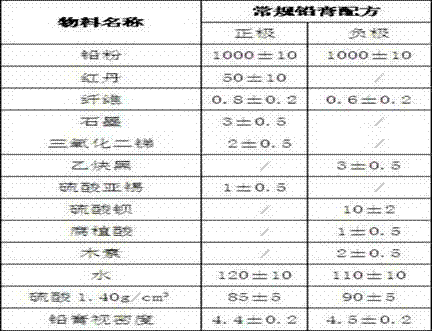

Embodiment 1

[0072] It is composed of lead paste on the positive electrode and lead paste on the negative electrode. The lead paste on the positive electrode is made of: 1000kg of lead powder, 1.5kg of fiber, 5kg of sodium borate, 135kg of water and 70kg of sulfuric acid. The apparent density is 4.2 g / cm 3 The lead paste on the negative electrode is made of: 990kg lead powder, 0.9kg fiber, 2.5kg sodium borate, 3kg polyaspartic acid sodium salt, 2kg barium stearate, 115kg water and 70kg sulfuric acid. The apparent density is 4.1 g / cm 3 of lead paste.

Embodiment 2

[0074] It is composed of lead paste on the positive electrode and lead paste on the negative electrode. The lead paste on the positive electrode is made of: 990kg of lead powder, 1.2kg of fiber, 4kg of sodium borate, 125kg of water and 65kg of sulfuric acid. The apparent density is 4.0 g / cm 3 The lead paste on the negative electrode is made of: 1000kg lead powder, 1.2kg fiber, 3kg sodium borate, 4kg polyaspartic acid sodium salt, 3kg barium stearate, 125kg water and 75kg sulfuric acid. The apparent density is 4.3 g / cm 3 of lead paste.

Embodiment 3

[0076] It consists of lead paste on the positive electrode and lead paste on the negative electrode. The lead paste on the positive electrode is made of: 1010kg of lead powder, 1.8kg of fiber, 6kg of sodium borate, 145kg of water and 75kg of sulfuric acid. The apparent density is 4.4 g / cm 3 The lead paste on the negative electrode is made of: 1000kg lead powder, 1.2kg fiber, 3kg sodium borate, 4kg polyaspartic acid sodium salt, 3kg barium stearate, 125kg water and 75kg sulfuric acid. The apparent density is 4.3 g / cm 3 of lead paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com