Optical filter

An optical filter and light source technology, applied in the field of optical filters, can solve problems such as image quality degradation, and achieve the effect of excellent productivity and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

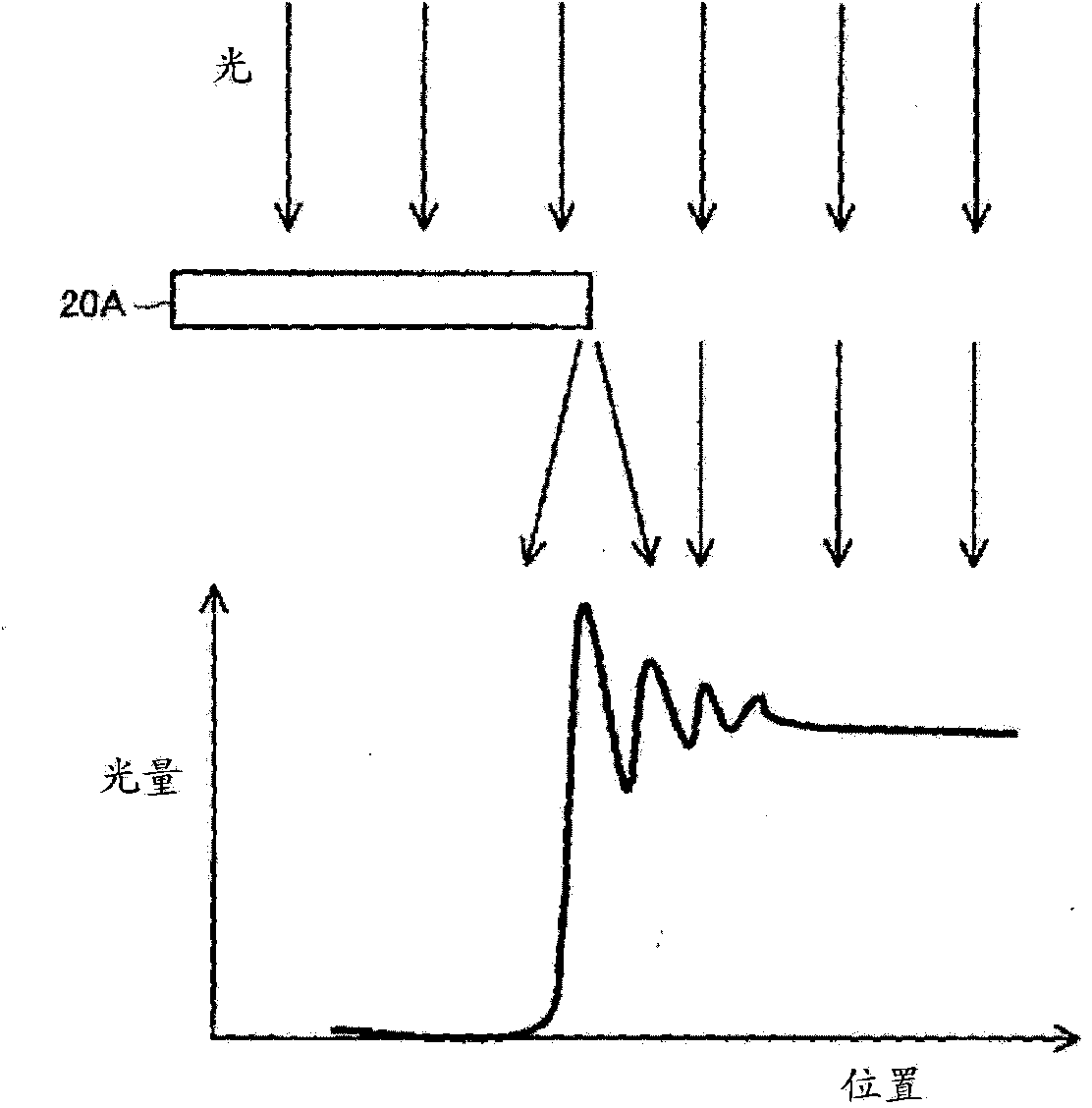

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

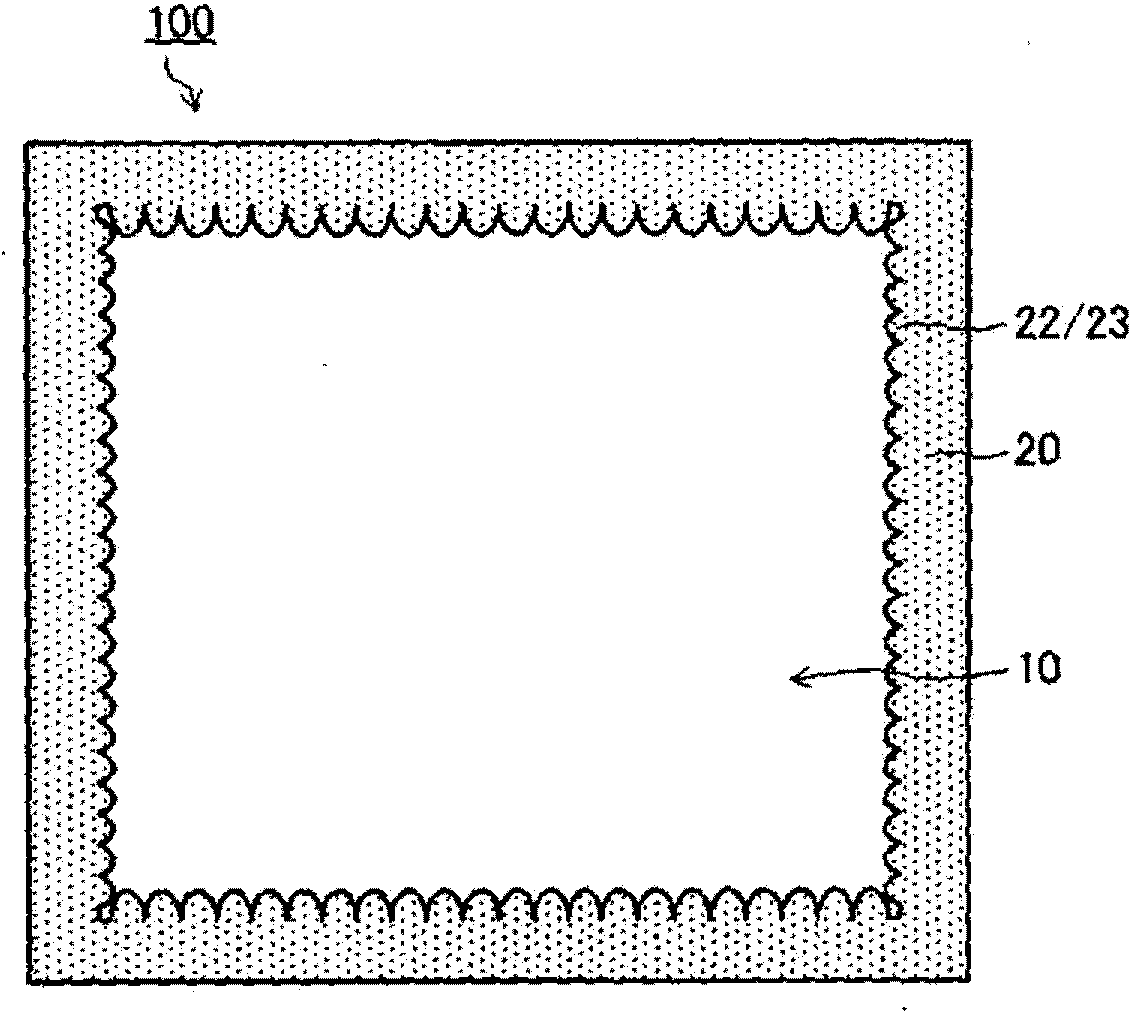

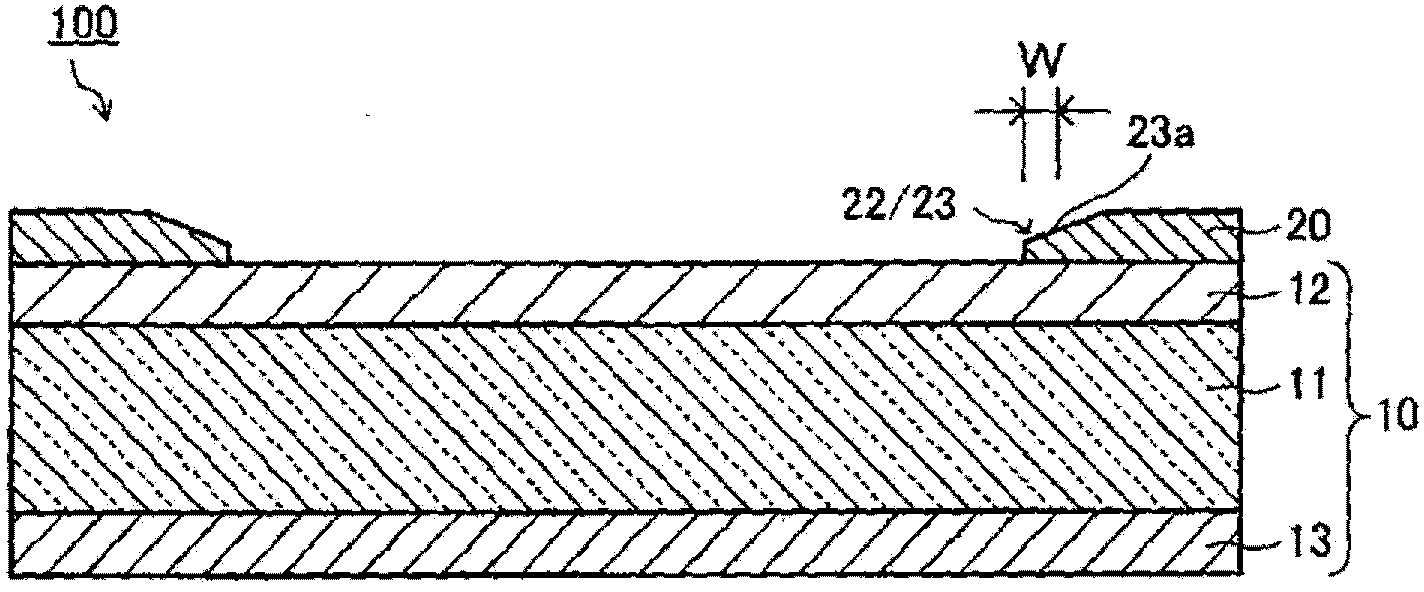

[0121] On one surface of a 40mm×40mm×0.3mm gusseted infrared-absorbing glass (NF-50 glass manufactured by Asahi Glass Co., Ltd.), silicon dioxide (SiO2) is alternately laminated by vacuum deposition. 2 ; refractive index 1.45 (wavelength 550nm)) layer and titanium dioxide (TiO 2 ; Refractive index 2.32 (wavelength 550nm)) layer to form a dielectric multilayer film (34 layers). In addition, an antireflection film is formed on the other surface of the infrared-absorbing glass.

[0122] On the entire surface of the above-mentioned dielectric multilayer film, a light-shielding ultraviolet curable acrylate resin was coated with a thickness of 1.2 μm by spin coating, and after heating, a photomask having irregular irregularities on the inner peripheral surface of the opening was applied. Irradiate its surface with a high-pressure mercury lamp at 100mJ / cm 2 UV light to cure it. Thereafter, unexposed portions were removed with a developing solution, followed by heating to manufactu...

Embodiment 2)

[0125] Carried out in the same manner as in Example 1, silicon dioxide (SiO 2 ; refractive index 1.45 (wavelength 550nm)) layer and titanium dioxide (TiO 2 ; Refractive index 2.32 (wavelength 550nm)) layer to form a dielectric multilayer film (34 layers). In addition, a three-layer anti-reflection film is formed on the other surface of the infrared-absorbing glass.

[0126] On the surface of the above-mentioned dielectric multilayer film, use the first screen plate with irregular unevenness on the inner peripheral surface of the opening to coat and add light-shielding resin ink (containing black coloring pigment), silica fine powder (average particle size (D50 ) 4.7 μm) and a solvent and uniformly mix the prepared coating solution, and heat to form the first coating film. Next, use a second screen with a smaller opening than the first screen to coat the above-mentioned coating solution on the first coating film again, heat it to form a second coating film, and manufacture a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com