Method for separating and extracting selenium from copper smelting wet process dust collection acid mud

A technology of wet dust and acid mud collection, applied in the direction of element selenium/tellurium, etc., to achieve the effect of simple operation method, high purity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

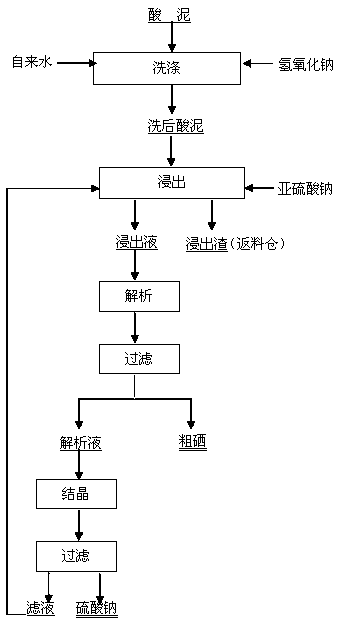

Image

Examples

Embodiment 1

[0020] ① Weigh 500g of acid mud, which contains 1.08% selenium (mass fraction), and wash it with 3000ml of 1% dilute sodium hydroxide solution at 30°C for 0.5h.

[0021] ② Without filtering, set the electric heating plate to heat to 70°C, then add 40g / L sodium sulfite, keep stirring for 1 hour, and then filter. The leaching residue contains 0.13% selenium, and the leaching rate of selenium is 90.2% based on the slag.

[0022] ③ Take 2000ml leach solution, add a certain amount of dilute sulfuric acid to adjust the pH value of the leach solution to 4.5. Heating, boiling, aging, filtering, the volume of the solution after analysis is 1900ml, the selenium content in the solution after analysis is 0.030g / L, and the crude selenium product obtained after drying contains 92.5% selenium.

[0023] In this example, the leaching rate of selenium was 90.2%, and the purity of crude selenium was 92.5%.

Embodiment 2

[0025] ① Weigh 500g of acid mud, which contains 1.22% selenium (mass fraction), and wash it with 4000ml of 1% dilute sodium hydroxide solution at 40°C for 1h.

[0026] ② Without filtering, set the electric heating plate to heat to 80°C, then add 60g / L sodium sulfite, keep stirring for 1 hour and then filter. The leaching residue contains 0.14% selenium, and the leaching rate of selenium is 91.6% based on the slag.

[0027] ③ Take 3000ml leach solution, add a certain amount of dilute sulfuric acid to adjust the pH value of the leach solution to 5.0. Heating, boiling, aging, filtering, the volume of the solution after analysis is 2800ml, the selenium content in the solution after analysis is 0.050g / L, and the crude selenium product obtained after drying contains 94.3% selenium.

[0028] In this example, the leaching rate of selenium was 91.6%, and the purity of crude selenium was 94.3%.

[0029] The experimental data in the two examples are shown in Table 1 below:

[0030] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com