Energy-efficient and environment-friendly fresh ready-mix concrete improving agent

An energy saving, environmental protection, concrete technology, applied in the field of building materials, can solve the problems of large slump loss, many bubbles, fast slump loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

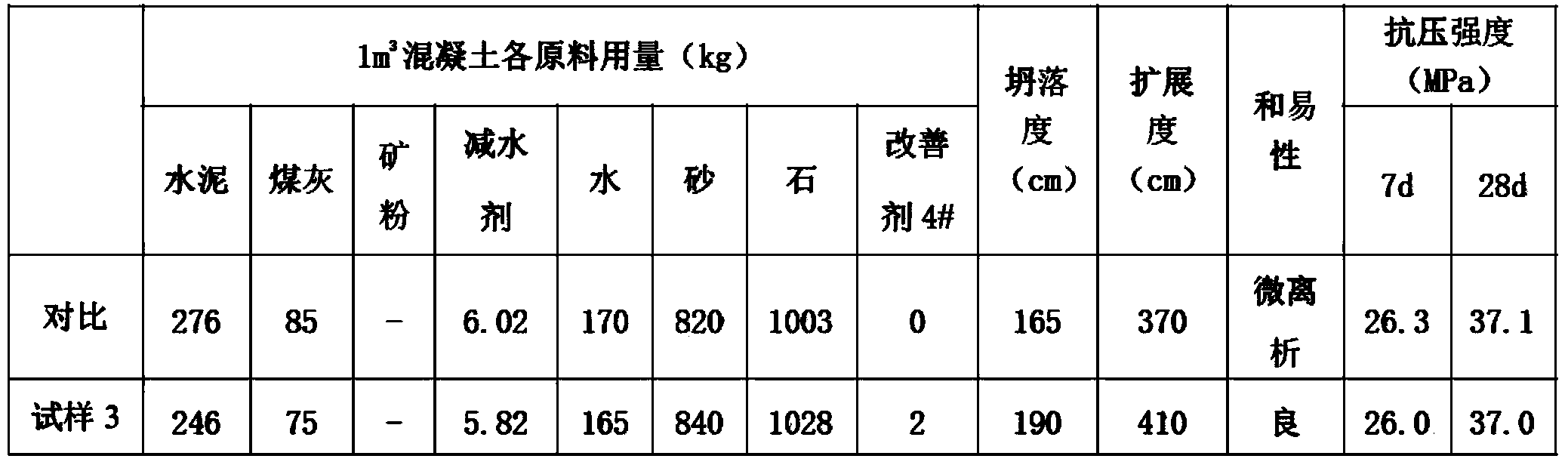

Examples

preparation example Construction

[0026] The preparation method of the improving agent of the present invention comprises the following steps: weighing the raw materials of each component according to the proportion, adding them into a reaction kettle, stirring and mixing them evenly to obtain the finished product.

[0027] The improver of the present invention is used for fresh concrete, preferably, the improver is 0.08-0.2wt% of the concrete. The preparation method of concrete can be any method well known to those skilled in the art, and there is no special limitation. Preferably, the improver is added to the mixture of water and water reducer, and then mixed with conventional aggregate and cementitious material to form a concrete material.

[0028] The invention provides a scientific formula aiming at the weak link in the concrete transition zone, and utilizes the characteristics of organic high molecular polymers (polyvinyl alcohol, polyvinyl chloride, thickener, dispersant) to distribute them between the ...

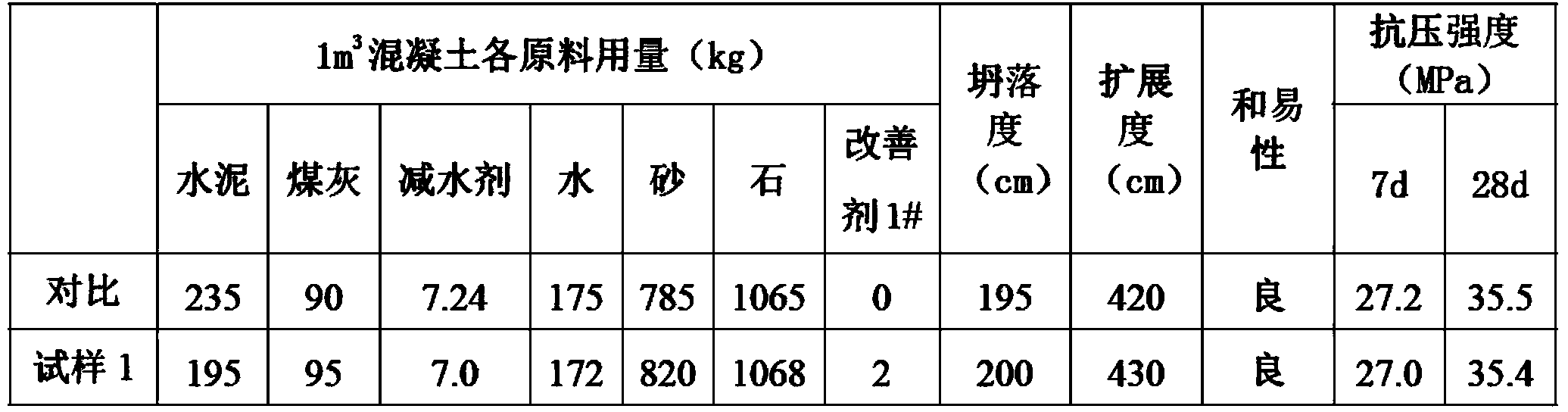

Embodiment 1

[0031] Weigh each component raw material: 25 parts of isopropanolamine, 5 parts of carboxymethyl cellulose ether, 3 parts of fatty alcohol polyoxyethylene ether, 5 parts of polyvinyl alcohol, dispersant (methyl naphthalene sulfonate formaldehyde condensation 40 parts of water) and 22 parts of water; add to the reaction kettle, mix and stir for 2 hours at room temperature, and obtain fresh concrete improver 1#.

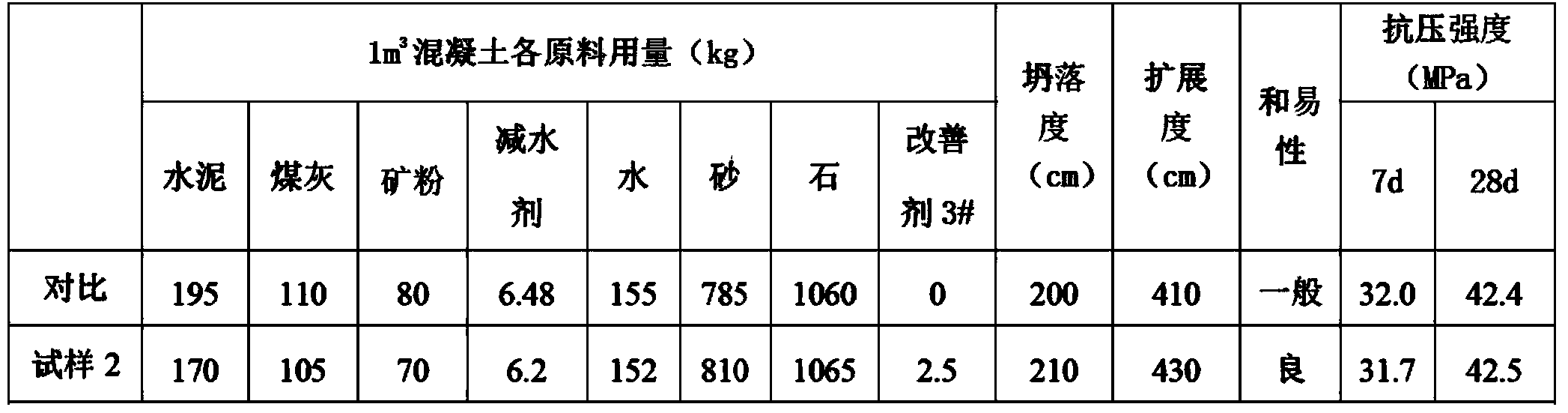

Embodiment 2

[0033] Weigh each component raw material: 35 parts of diisopropanolamine, 3 parts of carboxyethyl cellulose ether, 4 parts of fatty alcohol polyoxyethylene ether, 6 parts of polyvinyl chloride, 35 parts of polycarboxylate sodium salt dispersant, 17 parts of water Parts; add to the reaction kettle, mix and stir for 2 hours at room temperature to obtain fresh concrete improver 2#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com