Selective hydrogenation method for alpha-methyl styrene

A technology for selective hydrogenation of methyl styrene, which is applied in hydrogenation to hydrocarbons, bulk chemical production, chemical recovery, etc., can solve problems such as high operating costs, complex reaction procedures and reaction devices, and achieve cost savings and eliminate The effect of simple process and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

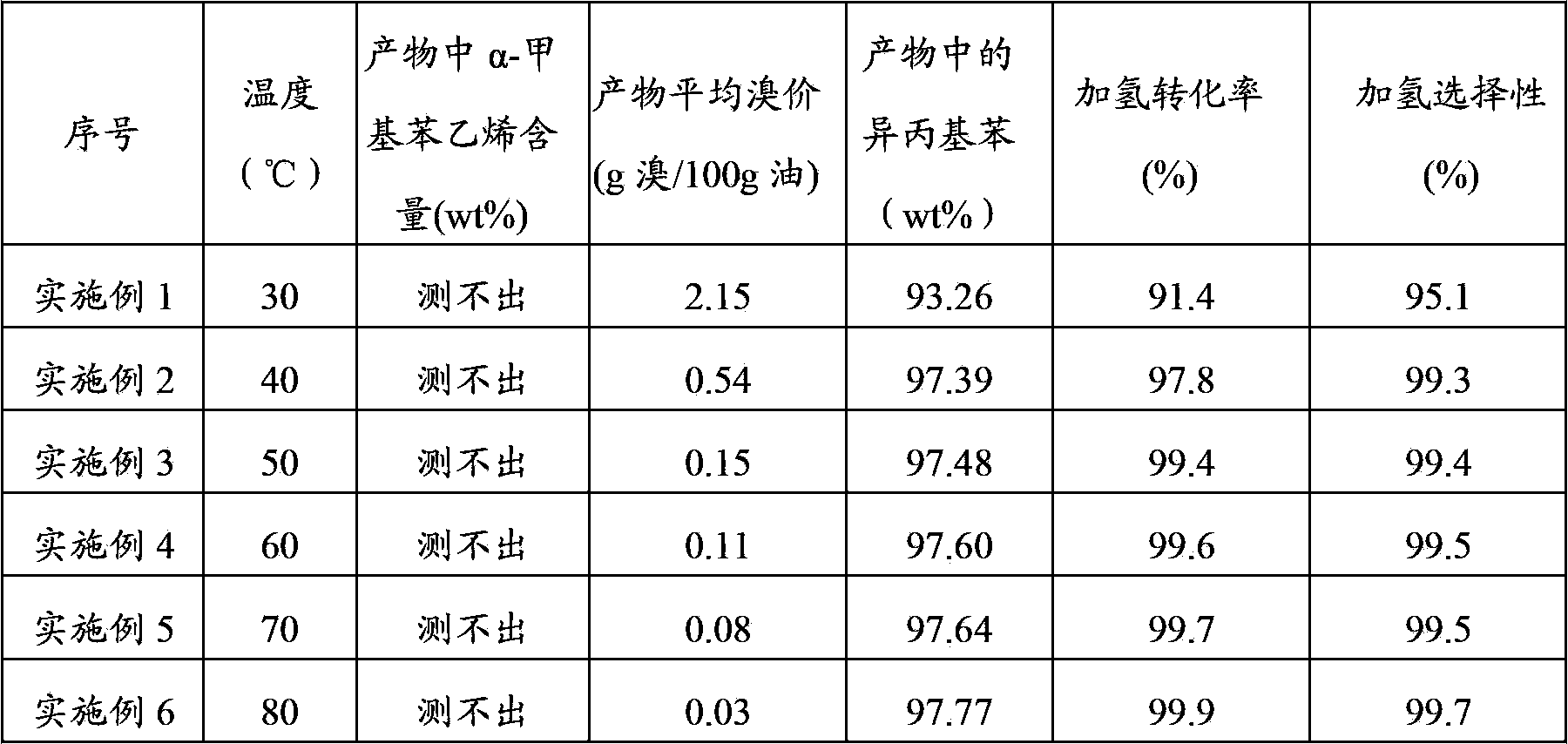

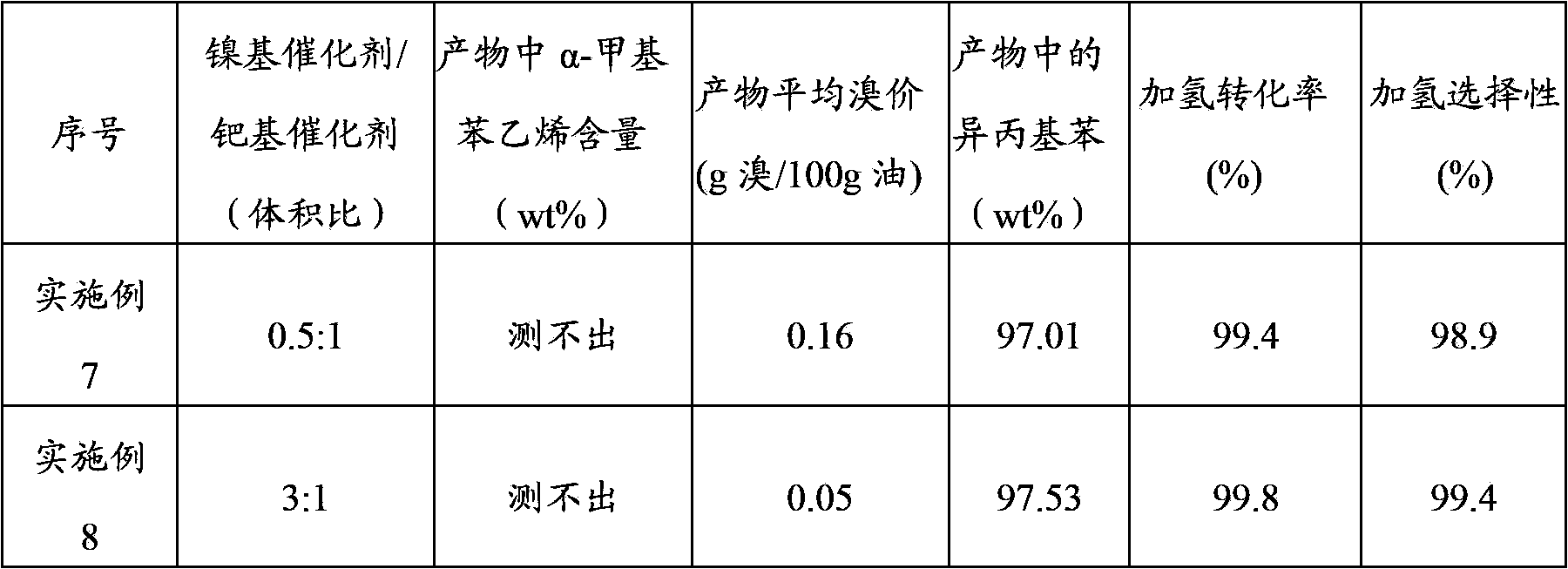

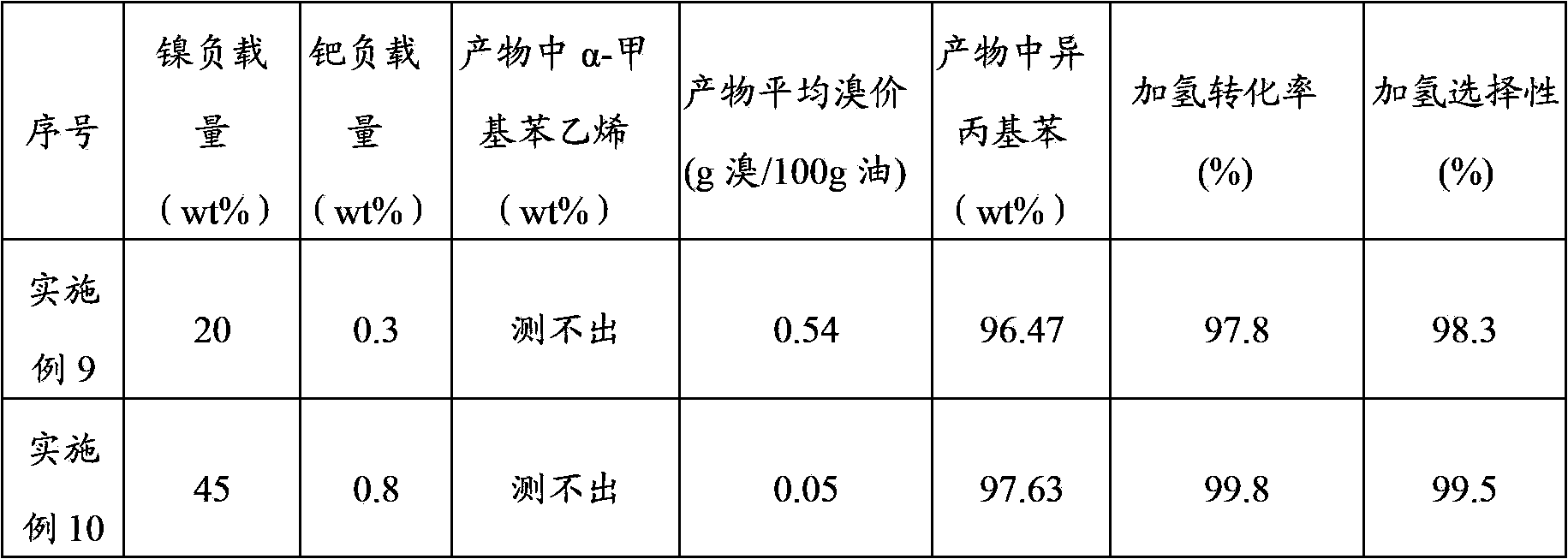

Examples

Embodiment 1

[0027] Mix aluminum sulfate with a content of 28.49 grams in terms of alumina and sodium silicate with a content of 56.98 grams in terms of silicon oxide (the weight ratio of aluminum oxide / silicon oxide is 1 / 2) to form 2000 ml of glue solution. Under conditions of pH 6.0, normal pressure and strong stirring, 1000 ml of nickel nitrate aqueous solution with a content of 114.53 g in terms of nickel oxide was added to the above-mentioned alumina-silica gel solution, precipitated for 40 minutes, filtered, and used 20 times the filter cake Volume of deionized water was washed for 40 minutes, filtered, washed again, and filtered again, and this process was repeated four times.

[0028] The filter cake was dried at 100°C for 10 hours, roasted at 500°C for 5 hours, cooled to room temperature, ground into powder, and made into a cylinder to obtain a nickel content of 44.1wt% and a particle size of Ф(2 ~6)×(2~5)mm nickel-based catalyst.

[0029] Take the specific surface area as 110 me...

Embodiment 2

[0035] The process of Example 1 was repeated, except that the reaction temperature was changed to 40° C., and the results are shown in Table 1.

Embodiment 3

[0037] The process of Example 1 was repeated, except that the reaction temperature was changed to 50° C., and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com