Preparation and purification method of heparin hexasaccharides containing N-unsubstituted glucosamine

A technology of glucosamine heparin and heparin pyridine hexasaccharide, which is applied in the field of preparation and purification of natural products, and can solve problems such as high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

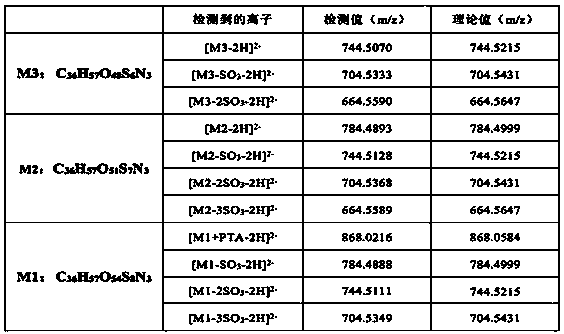

Examples

Embodiment 1

[0040] To prepare GlcNH containing 3 + Heparin hexasaccharide as an example:

[0041] 1 Preparation and purification of heparin sodium hexasaccharide

[0042] Heparinase Ⅰ, Ⅱ, Ⅲ Enzymolysis of low molecular weight heparin (3-8kD) at 37°C for 48h (commercially available) enzymatic hydrolysis of low molecular weight heparin through gel chromatography column (Bio-Gel P-10), the mobile phase is 0.2M NH 4 HCO 3 , at UV 232nm, measure the absorbance of the eluate. Collect the elution peak of heparin sodium hexasaccharide mixture, and then remove NH in 55°C water bath for 24h×3 4 HCO 3 , Freeze-dried at -80°C for 5 h. Then use SAX-HPLC, two-phase linear gradient elution under the conditions of 0-0.6M NaCl, 0.6-1.3M NaCl, separate and collect the highly sulfated heparin sodium hexasaccharide crude product. The specific parameters are as follows:

[0043] Chromatographic column: ProPac PA1 (9×250mm) Semi-Prep

[0044] Flow rate: 4ml / min

[0045] Mobile phase: A:pH3.5H ...

Embodiment 2

[0075] To prepare GlcNH containing 3 + Heparin hexasaccharide as an example:

[0076] 1 Preparation and purification of heparin sodium hexasaccharide

[0077] Heparinase Ⅰ, Ⅱ, Ⅲ Enzymolysis of low molecular weight heparin (3-8kD) at 37°C for 48h (commercially available) enzymatic hydrolysis of low molecular weight heparin through gel chromatography column (Bio-Gel P-10), the mobile phase is 0.2M NH 4 HCO 3 , at UV 232nm, measure the absorbance of the eluate. Collect the elution peak of heparin sodium hexasaccharide mixture, and then remove NH in 55°C water bath for 24h×3 4 HCO 3 , Freeze-dried at -80°C for 5 h. Then use SAX-HPLC, two-phase linear gradient elution under the conditions of 0-0.6M NaCl, 0.6-1.3M NaCl, separate and collect the highly sulfated heparin sodium hexasaccharide crude product. The specific parameters are as follows:

[0078] Chromatographic column: ProPac PA1 (9×250mm) Semi-Prep

[0079] Flow rate: 4ml / min

[0080] Mobile phase: A: pH3.5 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com