Polyphenylene sulfide-based heat conducting composite material and preparation method thereof

A thermally conductive composite material and a polyphenylene sulfide-based technology, which are applied in the field of polyphenylene sulfide-based thermally conductive composite materials and their preparation, can solve the problems of decreased tensile strength, poor thermal conductivity, and decreased mechanical properties, and achieve thermal conductivity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

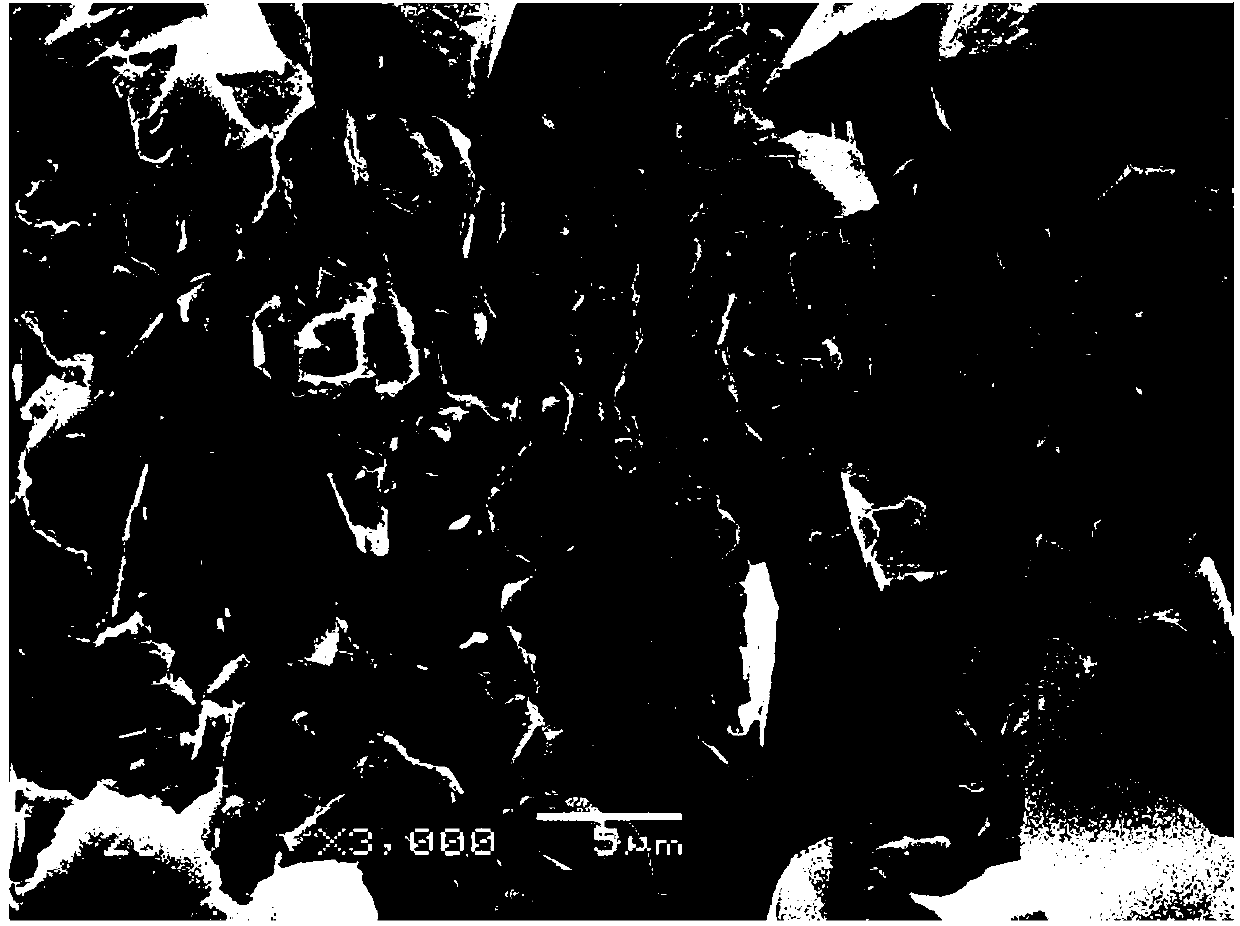

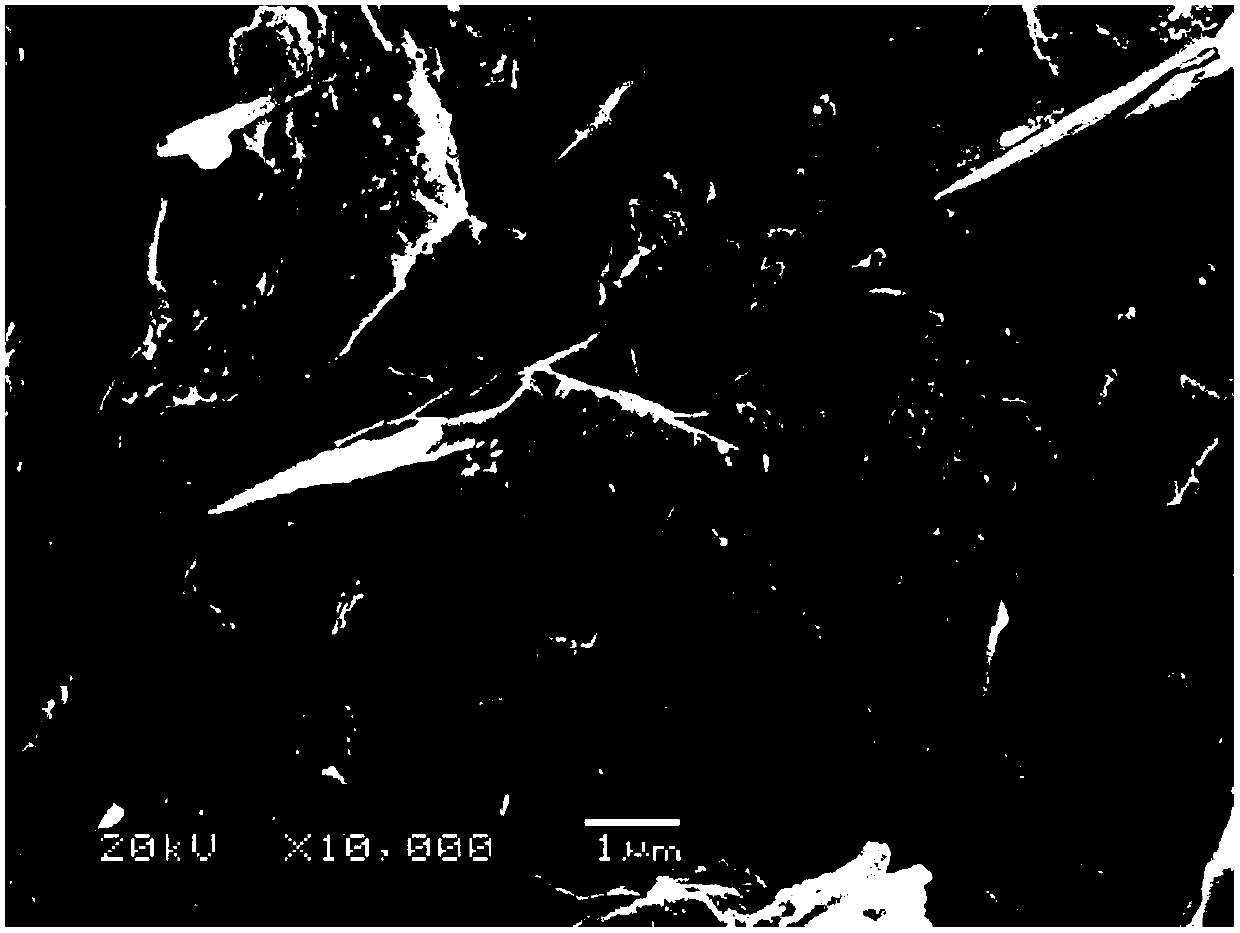

Image

Examples

preparation example Construction

[0050] The preparation method of the above-mentioned polyphenylene sulfide-based thermally conductive composite material includes the following steps and process conditions:

[0051] (1) Thermally conductive filler M and polyphenylene sulfide are melt blended to prepare thermally conductive masterbatch A, and the melting temperature is 290°C-320°C;

[0052] (2) Thermally conductive filler N is melt-blended with polyamide to prepare thermally conductive masterbatch B, and the melting temperature is 230-330°C;

[0053] (3) Finally, the heat-conducting masterbatch A and the heat-conducting masterbatch B are melt-blended to obtain a polyphenylene sulfide-based heat-conducting composite material, and the melting temperature is 290-330°C.

[0054] The preparation method of the polyphenylene sulfide-based thermally conductive composite material, the thermally conductive filler in the step (1) is first surface-treated with a coupling agent, and then the thermally conductive filler and p...

Embodiment 1

[0060] 10 parts of graphene oxide was melt-blended with 25 parts of polyphenylene sulfide at 310°C after being treated with 1 part of titanate; 30 parts of BN was added to 1 part of silane coupling agent KH560 and treated with PA66 was melt-blended at 290°C to prepare material B, and material A, material B and 3 parts of polyarylene sulfide amide were melt-blended at 310°C to obtain polyphenylene sulfide thermally conductive composite materials; the mechanical properties of the obtained materials, The thermal conductivity test results are listed in Table 1.

Embodiment 2

[0062] 5 Si 3 N 4 After being treated with 0.5 parts of titanate and melt blending with 20 parts of polyphenylene sulfide at 290°C, material A was prepared; 5 parts of BN were treated with 0.5 parts of silane coupling agent KH550 and melted with 30 parts of PA6 at 230°C Material B was prepared by blending, and material A, material B and 2 parts of carboxylated polyphenylene sulfide were melt blended at 310°C to obtain a thermally conductive polyphenylene sulfide composite material; the mechanical properties and thermal conductivity test results of the obtained material Listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com