Method and system for shortened wet steaming dyeing of loose fibers

A dyeing system and loose fiber technology, applied in the dyeing field, can solve the problems of uneven dyeing, high labor intensity, and low production efficiency, and achieve the effect of simple dyeing process, reduced production cost, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

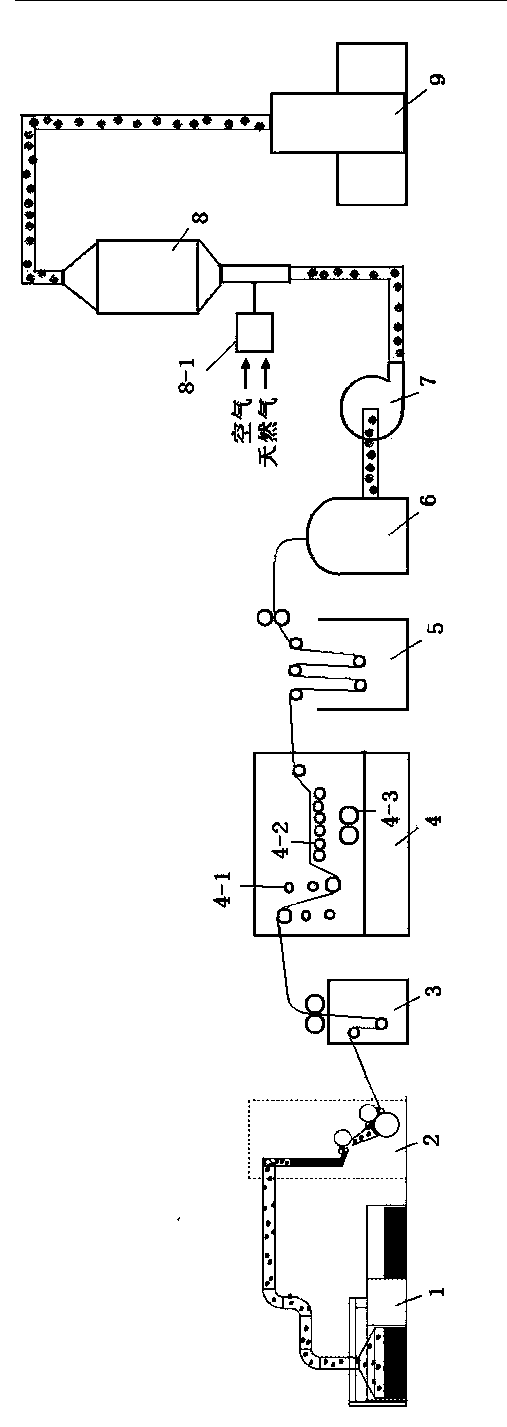

[0025] The loose fiber wet-short-steam dyeing system described in Example 1 includes a cotton grabbing machine 1, a web forming machine 2, a padding tank 3, a reaction box 4, a washing tank 5, an opening machine 6, a conveying fan 7, and a drying tower 8 And the fiber packaging device 9, the cotton grabbing machine 1 is connected to the entrance of the web forming machine 2 through a pipeline, and the padding tank 3, the reaction box 4, the washing tank 5 and the fiber opening machine 6 are distributed in the web forming machine 2 successively in an assembly line. On the outlet side, the outlet of the fiber opener 6 is connected to the inlet of the delivery fan 7 through a pipeline, the outlet of the delivery fan 7 is connected to the lower end of the drying tower 8 through a pipeline, and the upper end of the drying tower 8 is connected to the fiber packaging device 9 through a pipeline. The reaction box 4 contains an infrared heater 4.1, a hot air steam inlet 4.2 and a transf...

Embodiment 2

[0035] The loose fiber wet short steam dyeing system described in embodiment 2 is the same as embodiment 1.

[0036] The following is an example of dyeing cotton fiber with Argosol Red N-SB reactive dye in our bulk fiber wet short steam dyeing system:

[0037] Step 1. The cotton fiber is transported to the web forming machine 2 through the plucking machine 1, and the cotton fiber forms a uniform fiber layer with a width of 1.5m in the web forming machine 2, and the output speed of the fiber layer is 35m / min;

[0038] Step 2. Let the fiber layer formed in step 1 be dyed through the padding tank 3, the temperature of the padding solution is 30°C, the dyeing solution rate is controlled at 70%, and the dye prescription is: Argosol Red N-SB 2g / L , penetrant NF 1g / L, anti-swimming agent FR-MIV 3g / L, anti-staining salt Ludigol 1g / L;

[0039] Step 3. Make the fiber layer after padding in step 2 enter the reaction box 4 for reaction and color fixation. After the fiber layer passes thr...

Embodiment 3

[0045] The loose fiber wet short steam dyeing system described in embodiment 3 is the same as embodiment 1.

[0046] The following is an example of dyeing viscose fiber with Remazol Red RGB reactive dye in our bulk fiber wet short steam dyeing system:

[0047]Step 1. The viscose fiber is transported to the web forming machine 2 through the plucking machine 1, and the viscose fiber forms a uniform fiber layer with a width of 1.8m in the web forming machine 2, and the output speed of the fiber layer is 40m / min;

[0048] Step 2. make the fiber layer formed in step 1 be dyed through the padding tank 3, the temperature of the padding solution is 25°C, the dyeing solution rate is controlled at 70%, the dyestuff prescription is: remazol red RGB 10.8g / L, penetrating agent NF 1g / L, anti-swimming agent FR-MIV 5g / L, anti-staining salt Ludigol 1g / L, soda ash 10g / L;

[0049] Step 3. Make the fiber layer after padding in step 2 enter the reaction box 4 for reaction and color fixation. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com