In-situ gas-solid phase reaction pool for measuring high-temperature high-pressure dynamic field spectrum in situ

An in-situ reaction and reaction cell technology, applied in the field of instrument analysis, can solve the problems of increasing attenuation of detection light intensity and loss of Raman signal, etc., and achieve the effect of reducing thickness, reducing signal reduction and interference, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

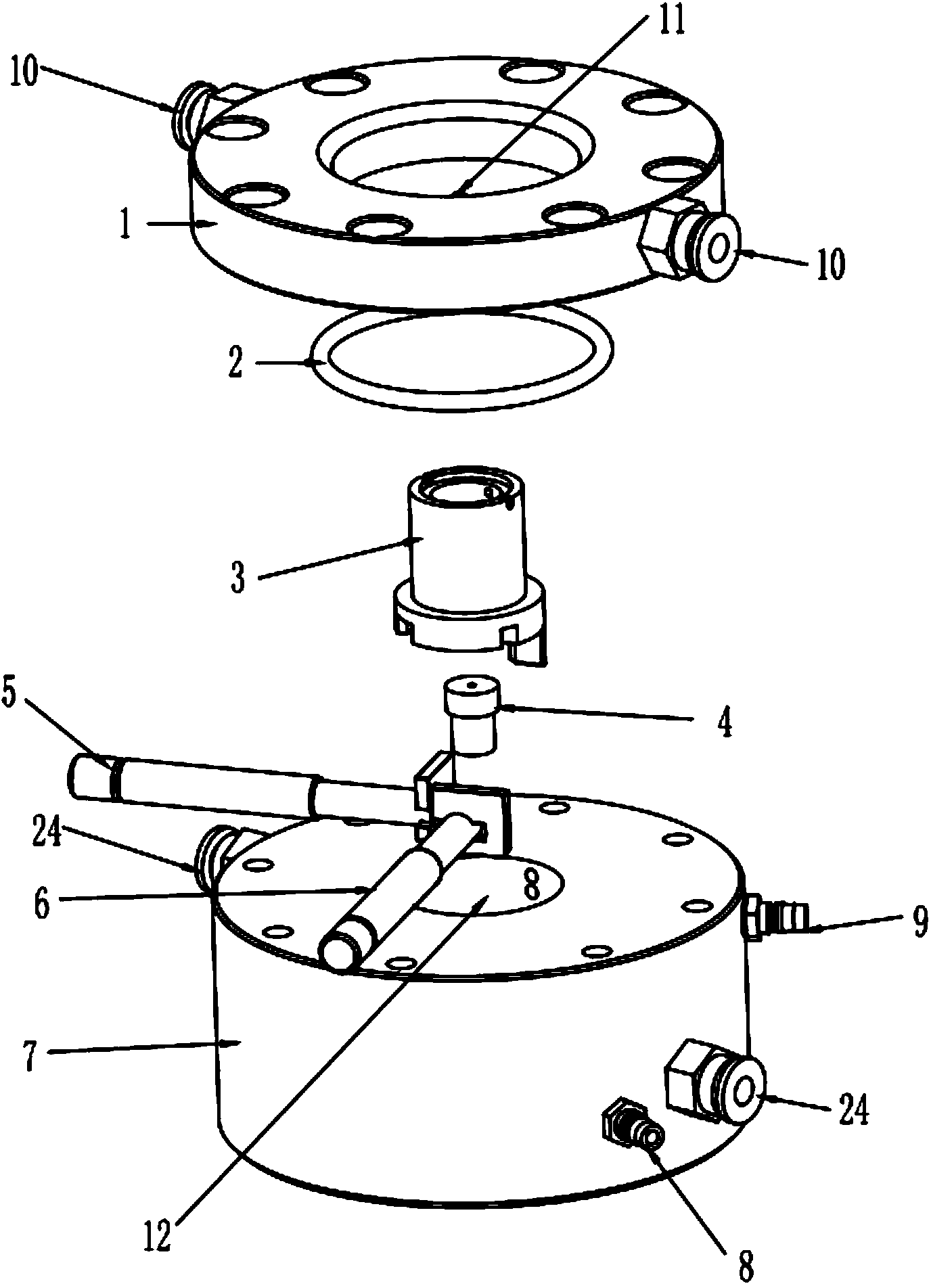

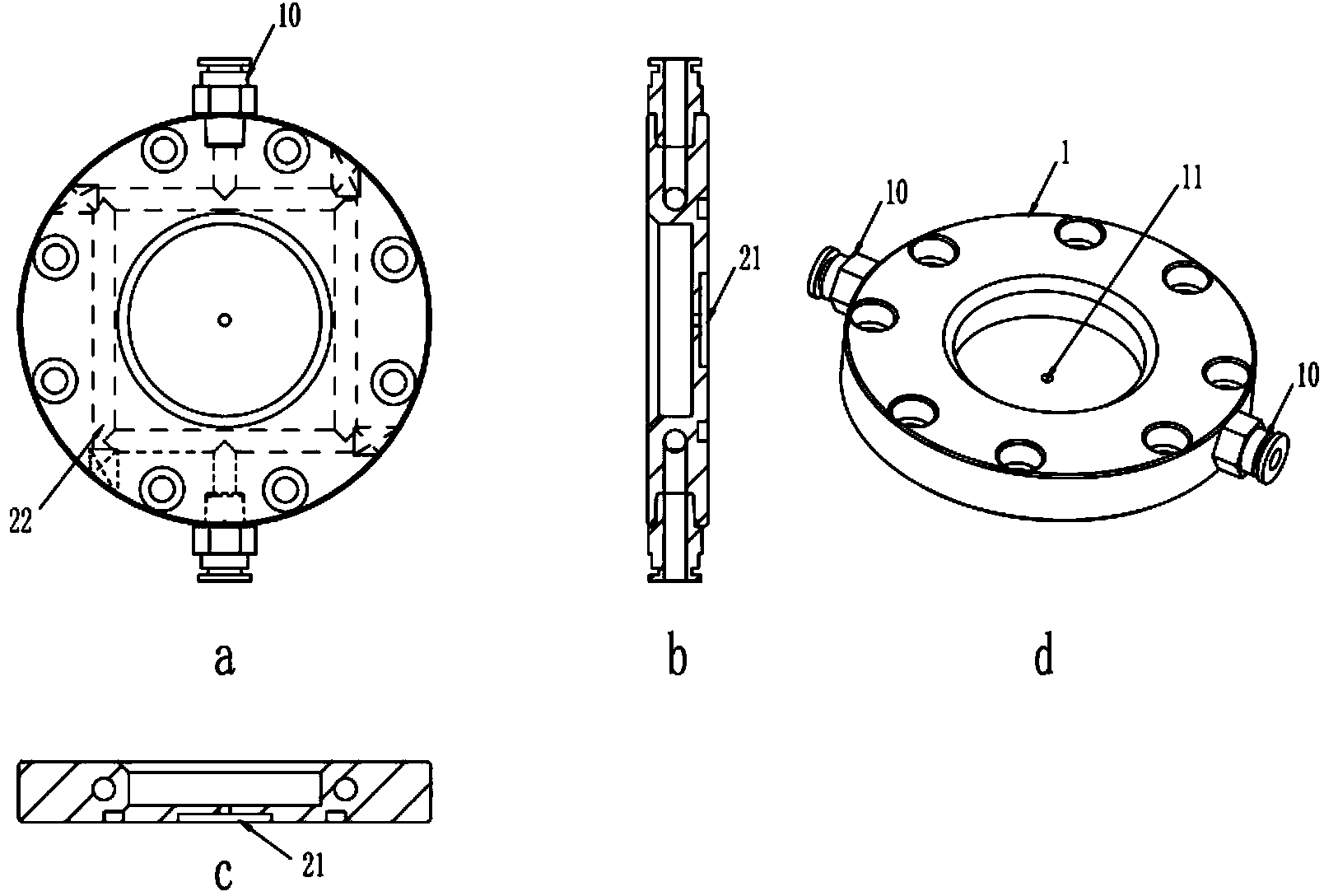

[0027] High temperature and high pressure gas-solid phase Raman reaction cell such as figure 1 , figure 2 , image 3 and Figure 4 shown. The main body of the reaction tank and the cover of the reaction tank are made of stainless steel. There are cooling water tanks inside the main body and the inside of the top cover. The main body also has air inlet and outlet channels and temperature control channels. The space size is 24mm in diameter and 16mm in depth. The outer diameter of the sample cell is 14mm, the inner diameter is 10mm, and the depth is 5mm. The diameter of the thin slice carrier is 12mm, and the depth is 1mm. The outer diameter of the sealing O-ring is 43.5mm and the inner diameter is 38.5mm. The diameter of the quartz window is 17mm, the thickness is 1mm, and the diameter of the light hole is 3mm. In the example, the adjustment rod penetrates the main body of the reaction tank and extends into the cavity, and is connected with the sample tank through the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com