Electric conducting plug and forming method of electric conducting plug

A technology of conductive plugs and conductive materials, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as performance degradation of semiconductor devices, and achieve the effect of good performance and avoidance of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

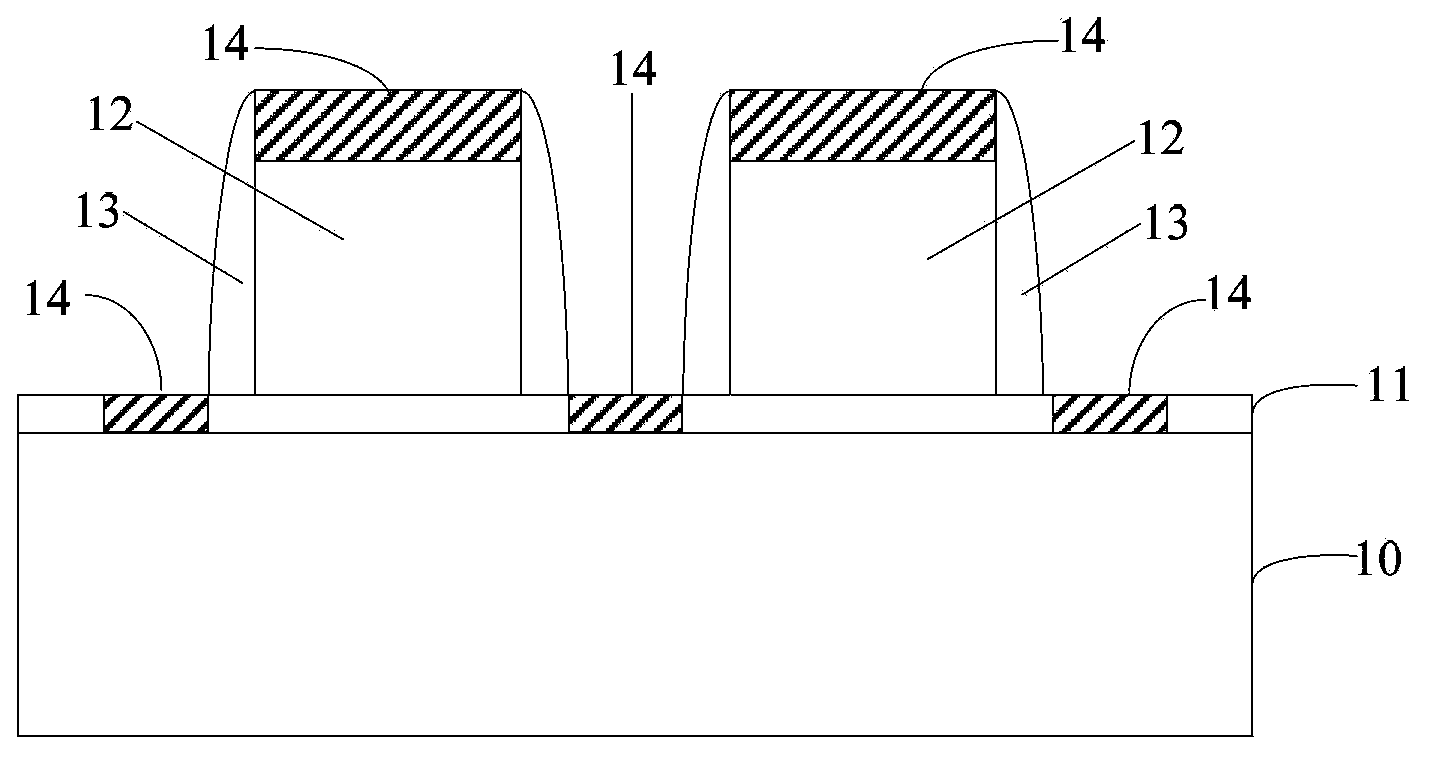

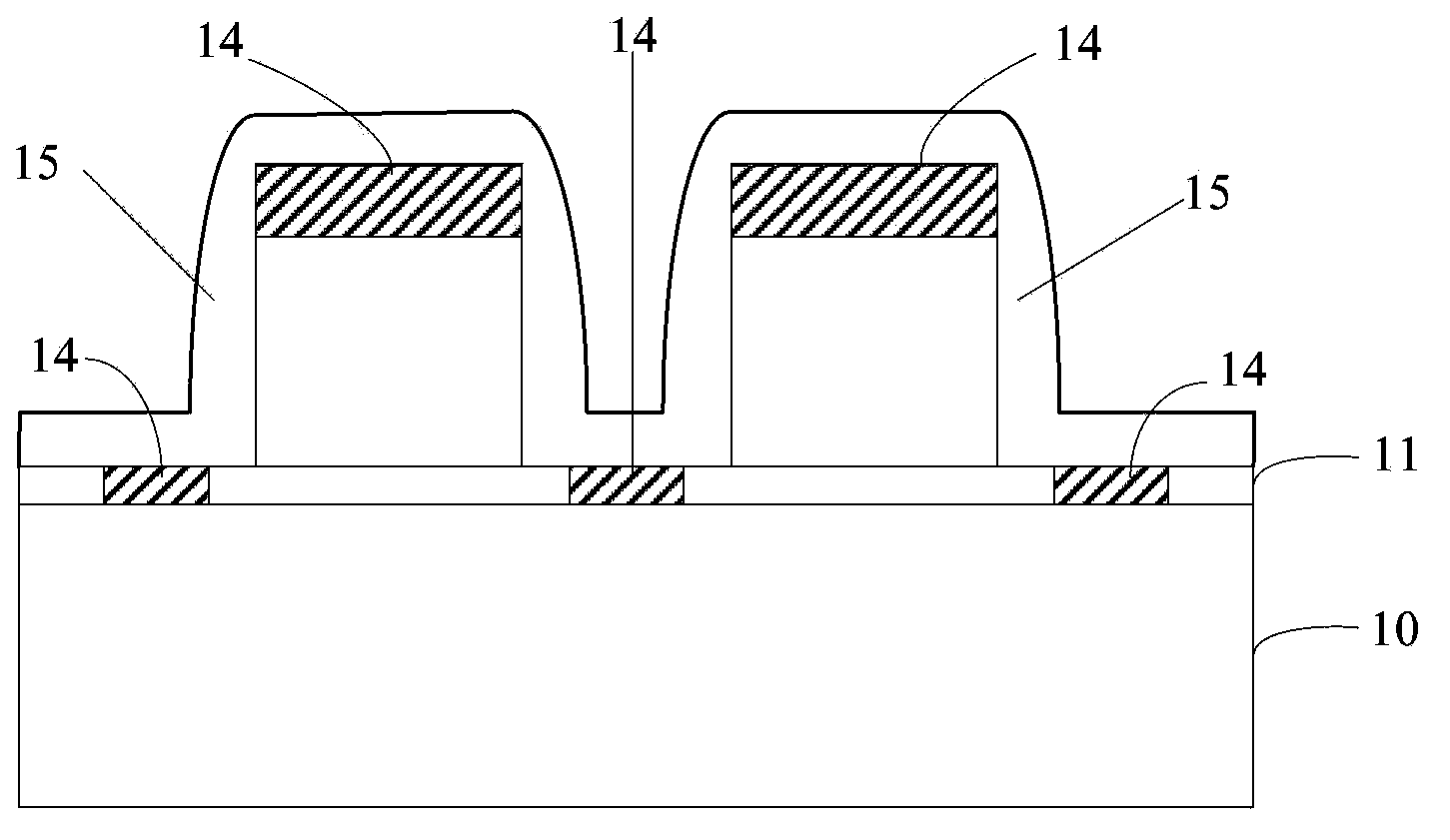

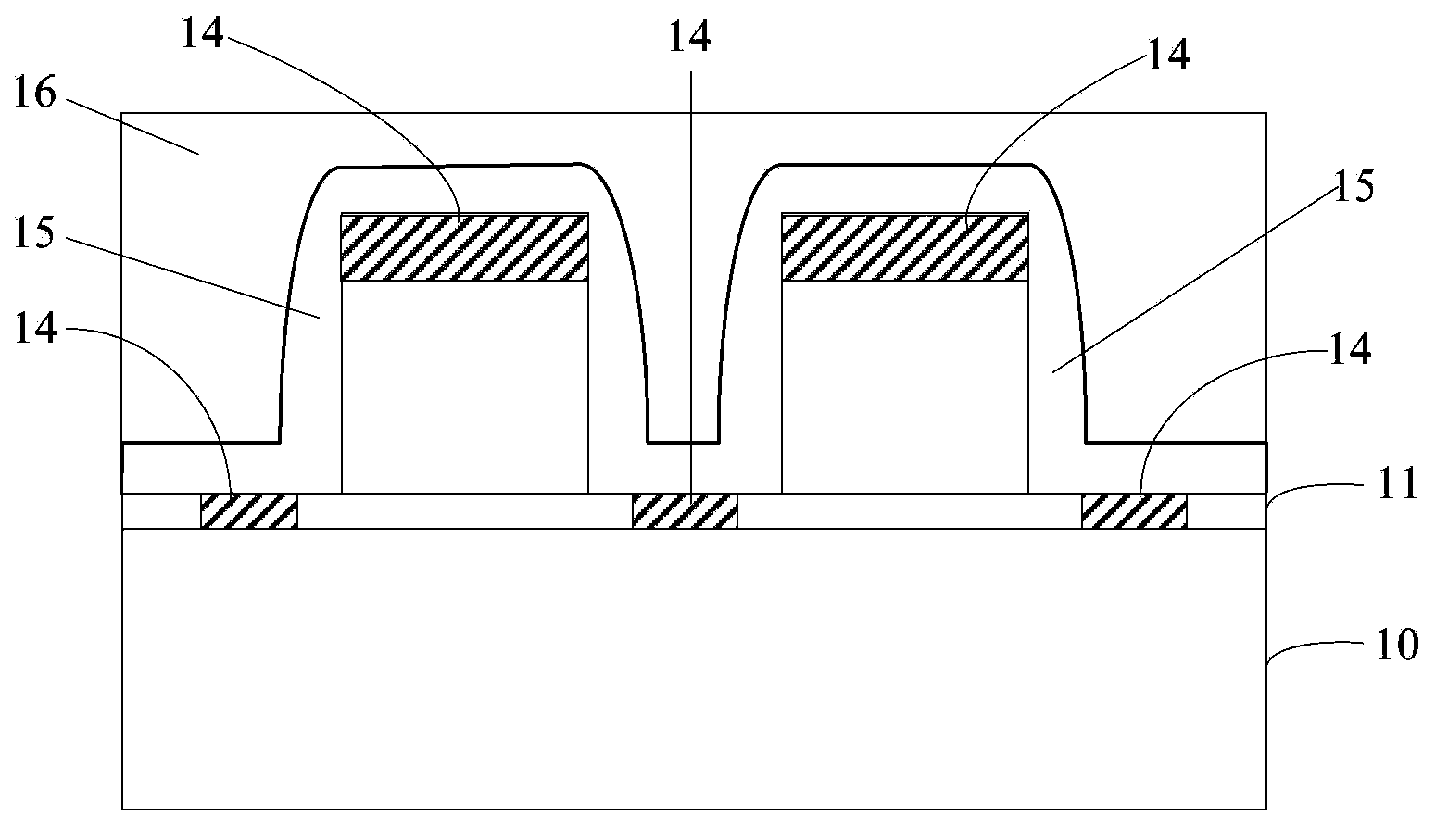

[0044] The inventor analyzed the formation method of the conductive plug in the prior art, and found that: in the process of forming the contact hole, during the process of etching the interlayer dielectric layer and the stress layer by using the ashing process, a polymer will be formed in the contact hole , so after the contact hole is formed, the contact hole needs to be cleaned to remove the polymer. However, the H typically used in the cleaning process 2 SO 4 and H 2 o 2 The mixed solution (SPM) will corrode the side wall of the stress layer. Especially when the material of the stress layer is diamond-like carbon, the SPM acidic solution will corrode the sidewall of the diamond-like carbon stress layer. When the sidewall of the stress layer is corroded, there will be direct contact between the gate and the conductive material in the contact hole, resulting in a short circuit between the gate and the conductive material in the adjacent contact hole, which will inevitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com