Organic thin-film transistor and manufacturing method thereof

An organic thin film and transistor technology, applied in the field of organic thin film transistors, can solve problems such as poor bias stability, high electrical performance, and difficult production, and achieve high bias stability, high mobility, and stable electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

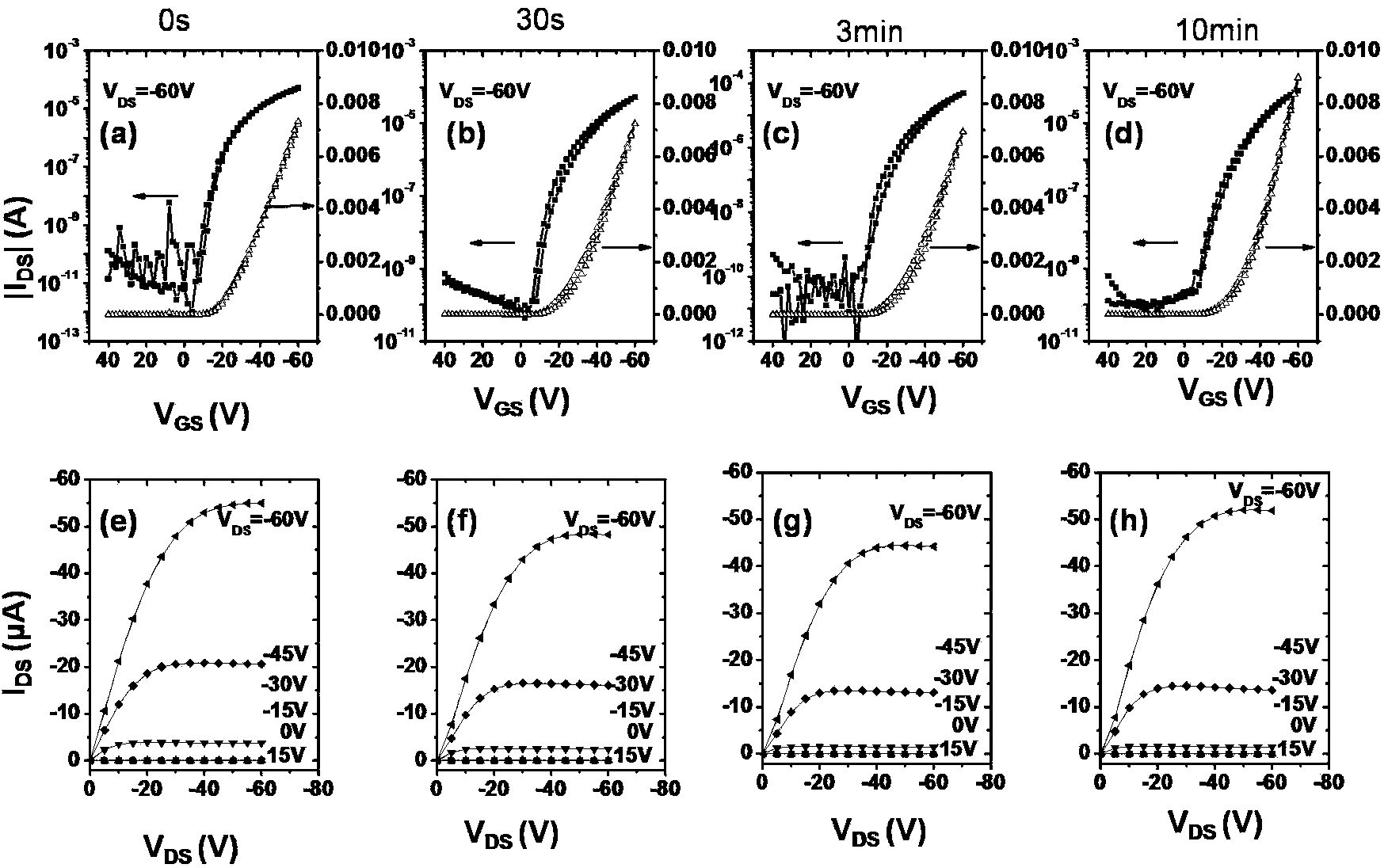

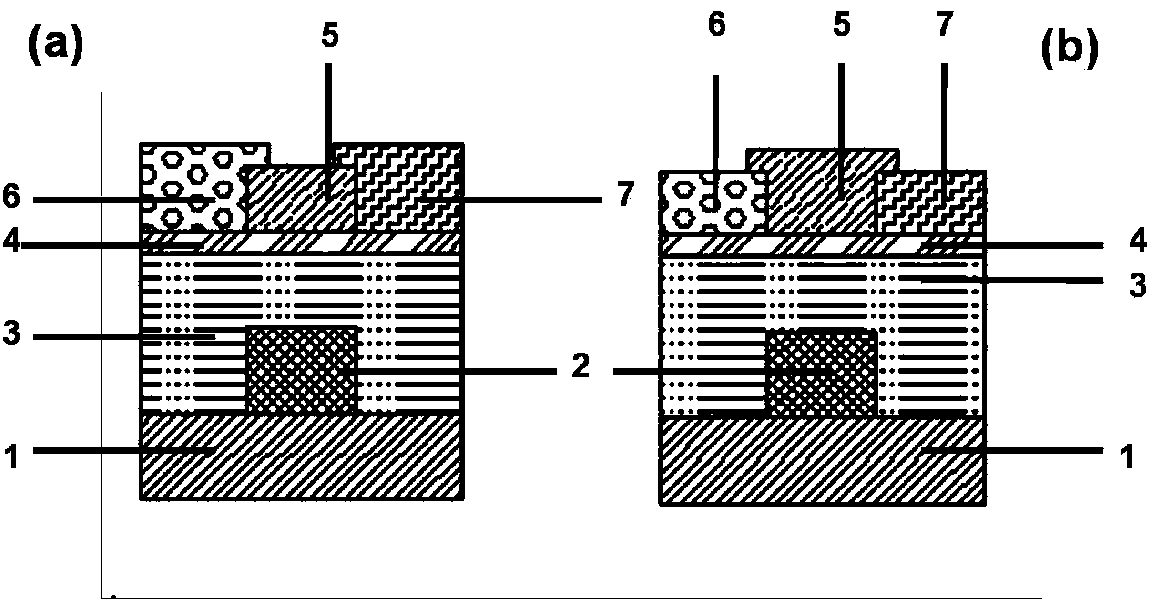

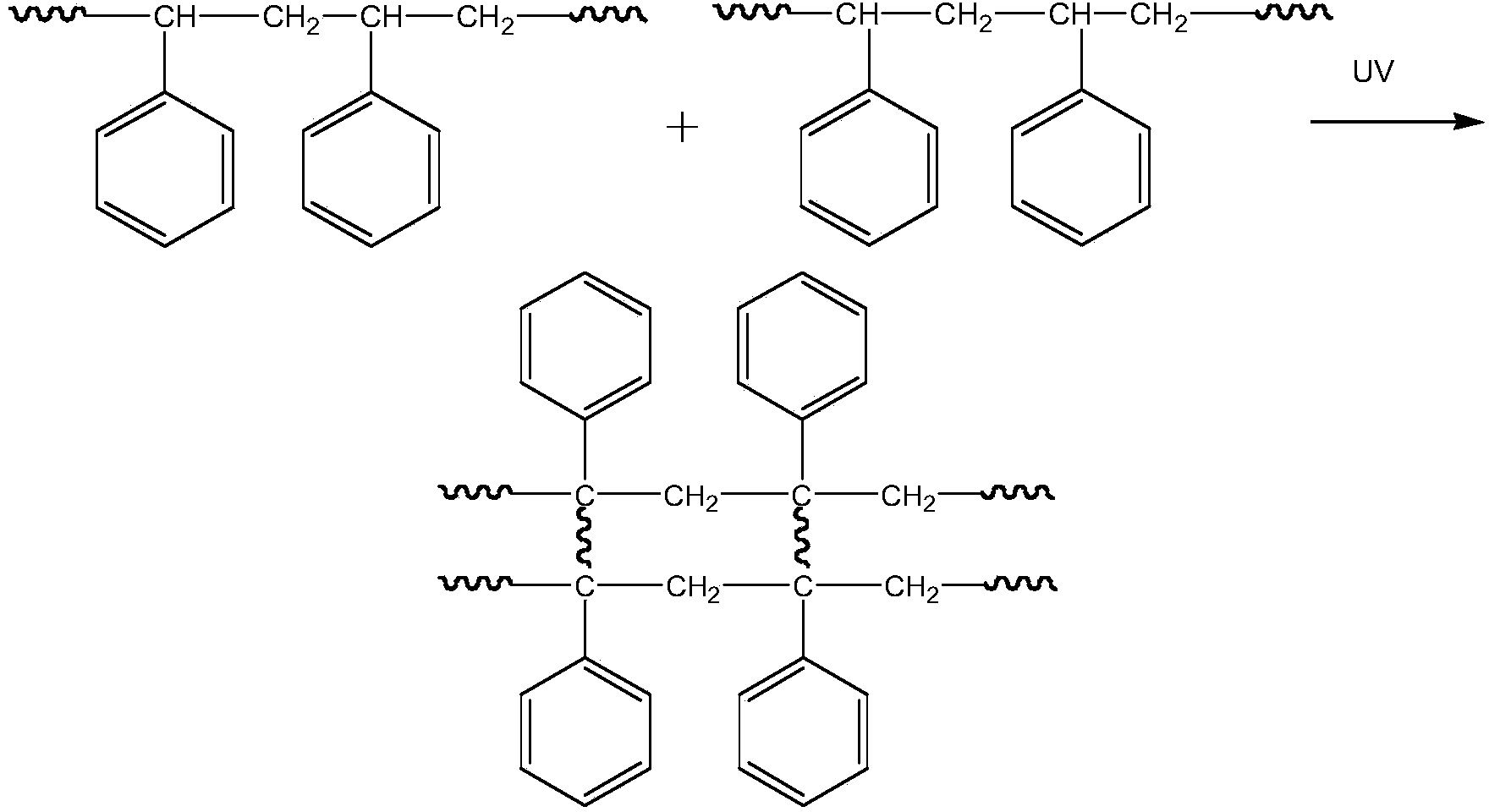

[0045] Such as figure 1As shown, the organic thin film transistor of this embodiment is covered with an insulating layer 3 on a substrate 1 provided with a gate electrode 2, and a surface modification layer 4 is covered on the insulating layer 3, and the surface modification layer 4 is cross-linked after being irradiated with ultraviolet light reaction, an organic semiconductor layer 5 and a source electrode 6 and a drain electrode 7 in ohmic contact with the organic semiconductor layer are provided on the surface modification layer after the crosslinking reaction, and the source electrode 6 and drain electrode 7 are connected through the organic semiconductor layer 5 . figure 1 (a) The semiconductor layer and the source electrode 6 and the drain electrode 7 are in the top contact form, and can also be used figure 1 The bottom contact form shown in (b).

[0046] The organic thin film transistor of this embodiment is prepared according to the following steps:

[0047] a. U...

Embodiment 2

[0058] Polystyrene can be changed into polyvinyl cinnamate, and all the other processing steps are the same as in Example 1.

Embodiment 3

[0060] Polystyrene can be replaced by poly-alpha-methylstyrene material, and the rest of the process steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com