Fuel injection device for internal combustion engine

A technology for a fuel injection device and a fuel injection valve, which is applied to the fuel injection device, the addition of non-fuel substances to the fuel, the charging system, etc., can solve the problems of increasing smoke and black smoke, decreasing fuel injection pressure, and deteriorating flammability, etc. Achieve the effect of preventing the increase of smoke and black smoke and preventing the drop of fuel injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] [First Embodiment]

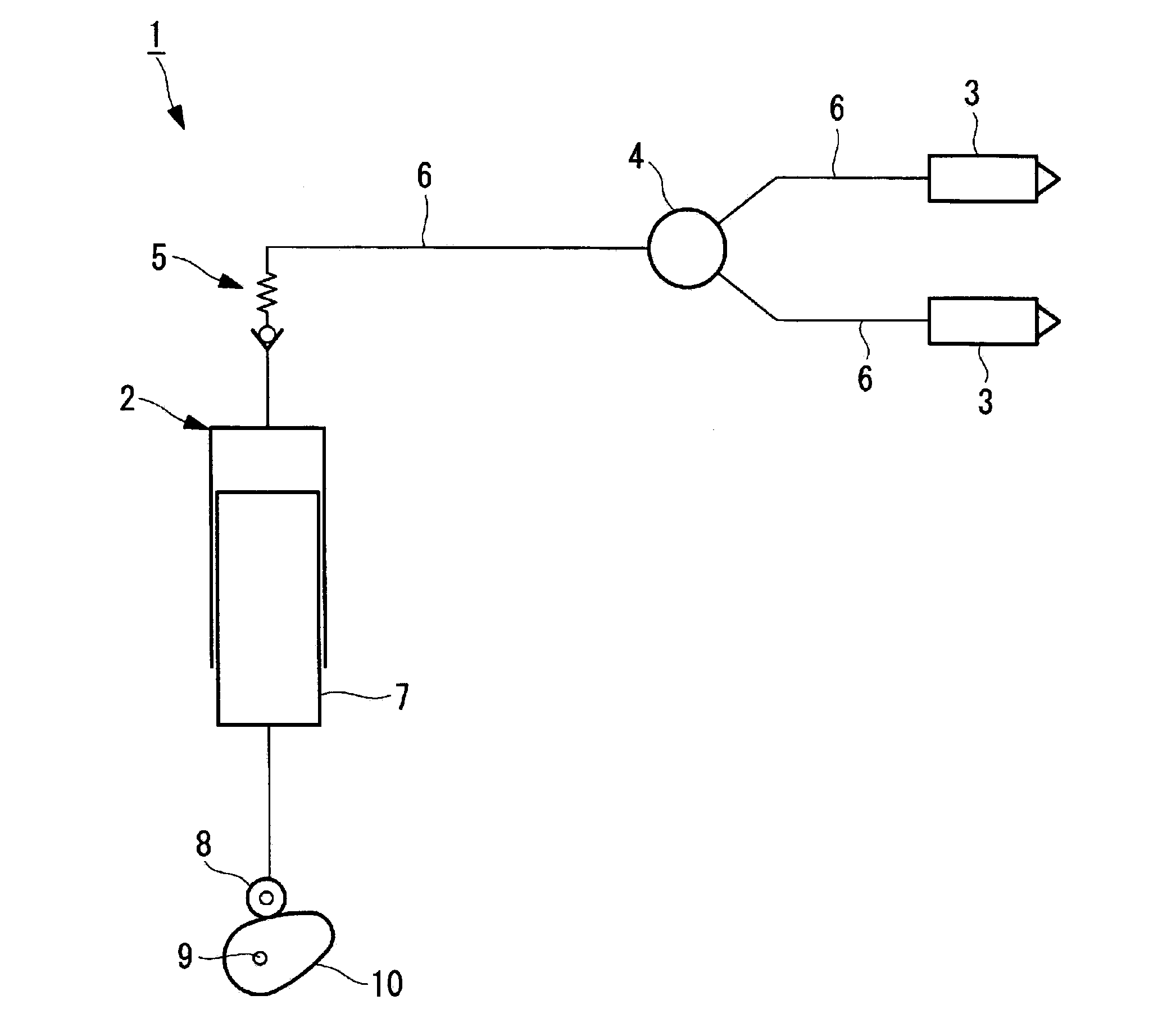

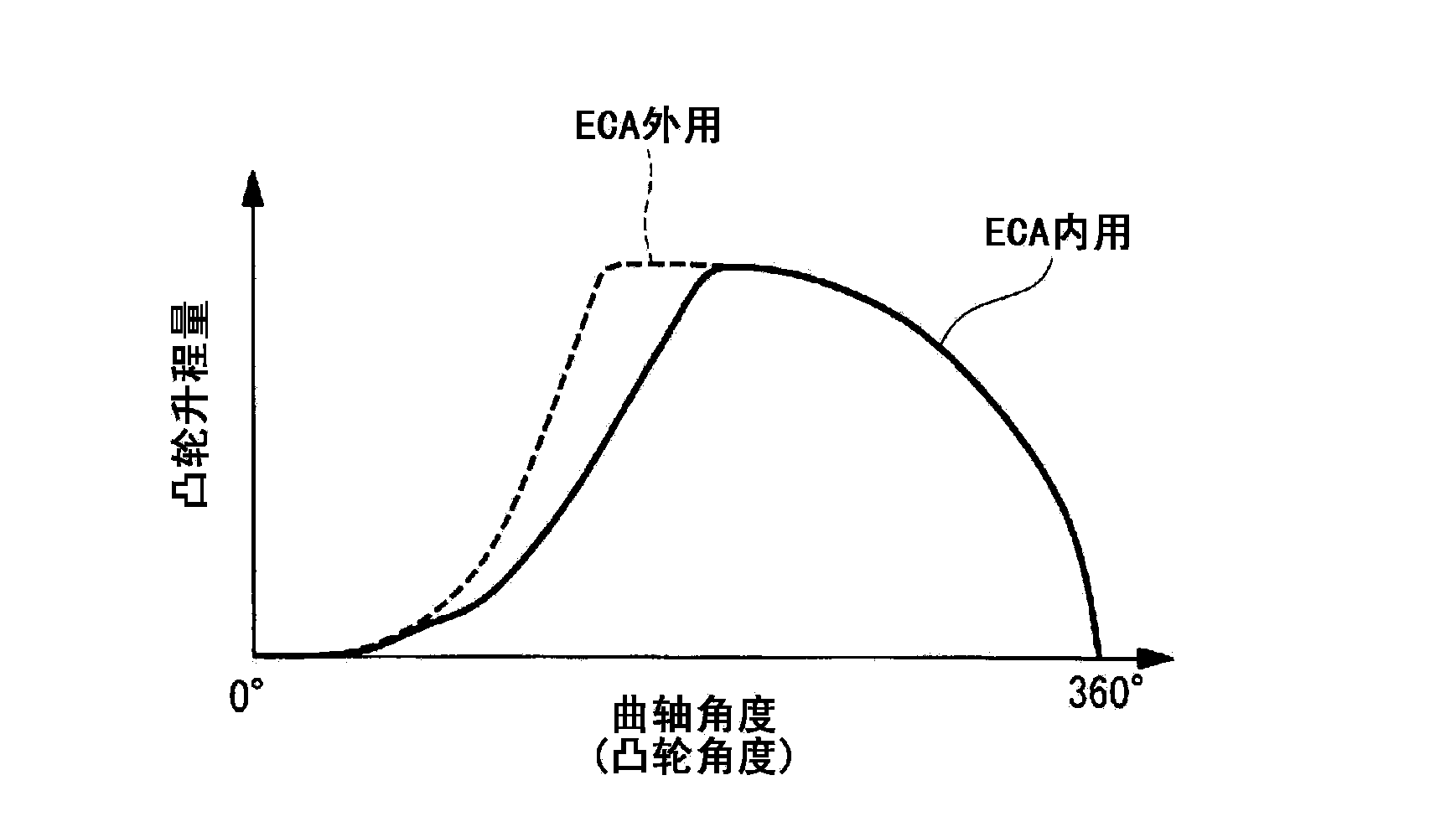

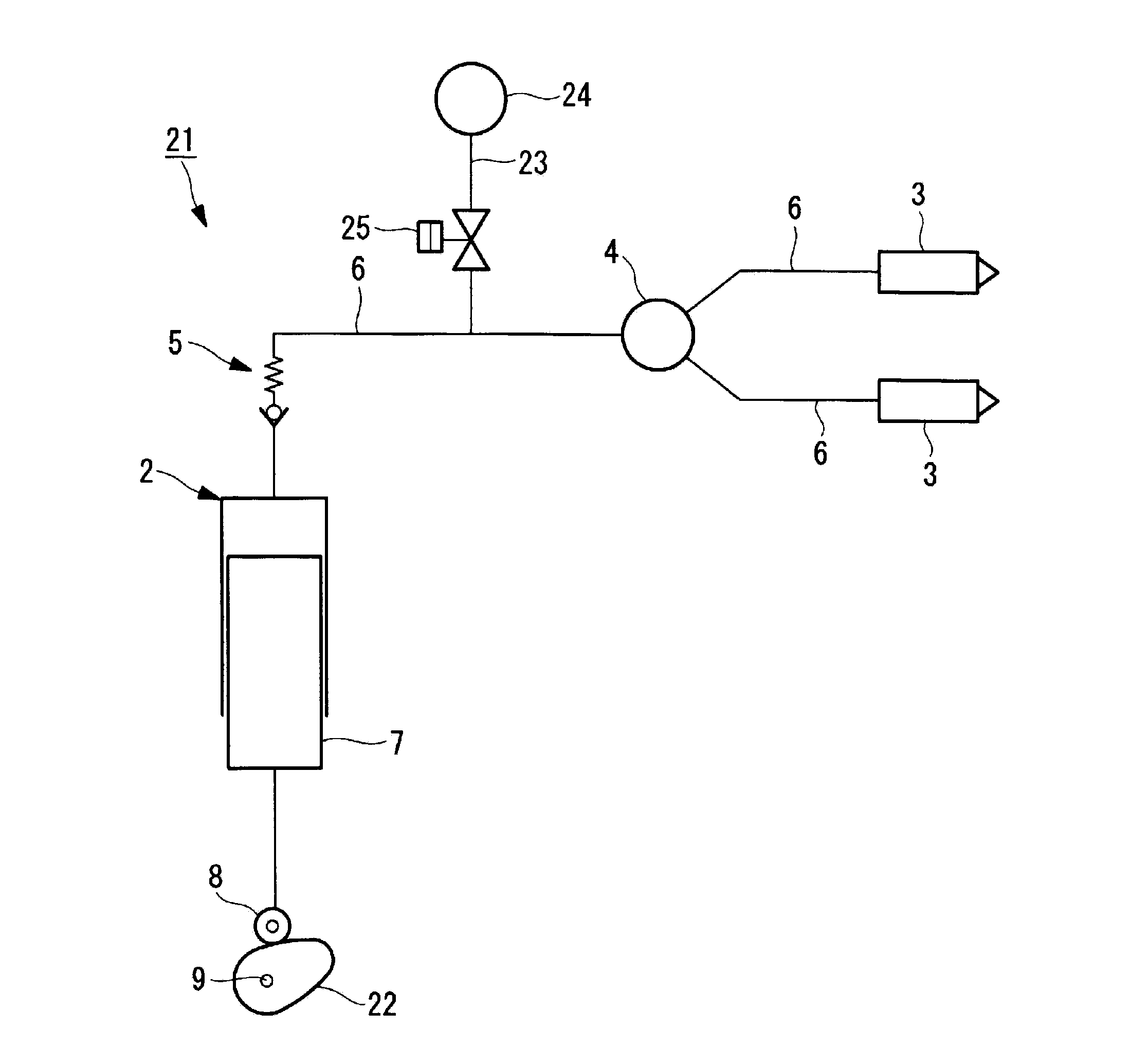

[0062] Now refer to figure 1 and figure 2 A fuel injection device for an internal combustion engine according to a first embodiment of the present invention will be described.

[0063] figure 1 is a schematic configuration diagram showing a fuel injection device for an internal combustion engine according to the present embodiment, figure 2 yes means figure 1 A graph showing the relationship between the amount of cam lift and the angle of the crankshaft (cam angle) for the cam shown.

[0064] In addition, the fuel injection device for an internal combustion engine of the present invention is mounted on an internal combustion engine (not shown) such as a large marine diesel engine.

[0065] Such as figure 1 As shown, the fuel injection device 1 of the internal combustion engine of the present embodiment, before entering the engine exhaust gas restricted sea area from outside the engine exhaust gas restricted sea area, for example, as disclose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com