Preparation method for silkworm pupa food, silkworm pupa food and application

A technology for silkworm chrysalis and food, which is applied to the preparation of silkworm chrysalis food, and the application fields of silkworm chrysalis, can solve the problems of easy collapse and deformation, high energy consumption, oxidation of nutrients, etc., achieve good flavor and taste, reduce equipment energy consumption, and improve health care. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

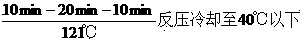

Embodiment 1

[0044] (1) Preparation of semi-dry silkworm chrysalis (first drying)

[0045] Select fresh silkworm chrysalis and dry until the moisture content is 50%;

[0046] (2) Preparation of mixed seasoning gel

[0047] Mix agar, carrageenan and white fungus superfine powder in a mass ratio of 2:2:3 to prepare a ternary premixed rubber powder, according to the ratio of premixed rubber powder: 8% (mass concentration) sucrose water = 1:25 Mix and swell into a colloid in a water bath at 85°C, then continue to add edible NaCl with a final concentration of 0.4% and stir evenly to obtain a ternary premixed glue, and mix the ternary premixed glue with water extract of shiitake mushrooms, pork paste and rosemary oil The solution is mixed according to a certain proportion, in which the amount of pork paste is 0.1% (accounting for the total mass of the ternary premixed rubber), the amount of water extract of shiitake mushrooms is 0.2% (accounting for the total mass of the ternary premixed rubber...

Embodiment 2

[0058] (1) Preparation of semi-dry silkworm chrysalis (first drying)

[0059] Select fresh silkworm chrysalis and dry to 60% moisture; the raw material requirements are to use fresh silkworm chrysalis 4-7 days after cocooning, remove diseased and dead pupae, and store the raw material in a 4°C cold storage before drying to prevent further development to the adult stage. The equipment can use a heat pump dryer to control the temperature at 50°C to 60°C, and dry the raw material until the water content of the raw material is 60%, which can prevent the extravasation of silkworm chrysalis juice during the subsequent piercing process.

[0060] (2) Preparation of mixed seasoning gel

[0061] Mix agar, carrageenan and tremella superfine powder in a ratio of 2:2:3 (mass ratio) to prepare a ternary premixed rubber powder, mix the rubber powder: 10% sucrose water = 1:20, and pass through After swelling into a colloid in a water bath at 90°C, continue to add a final concentration of 0.5...

Embodiment 3

[0072] (1) Preparation of semi-dry silkworm chrysalis (first drying)

[0073] Select fresh silkworm chrysalis and dry to 55% moisture; the raw material requires fresh silkworm chrysalis 4-7 days after cocooning, remove diseased and dead pupae, and store raw materials in a cold storage at 2°C before drying to prevent further development to the adult stage. The equipment can use a heat pump dryer, control the temperature at 55°C, and dry it until the moisture content of the raw material is 55%, which can prevent the extravasation of silkworm chrysalis juice during the subsequent piercing treatment.

[0074] (2) Preparation of mixed seasoning gel

[0075] Mix agar, carrageenan, and white fungus superfine powder in a ratio of 3:3:3 (mass ratio) to prepare a ternary premixed rubber powder. Mix the rubber powder: 10% sucrose water = 1:30. After swelling into a colloid in a water bath at 85°C, continue to add a final concentration of 0.4% edible NaCl and stir evenly to obtain a tern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com