A double-column circulation separation system and method for preparing tanshinone compounds

A separation system and compound technology, applied in the field of double-column circulation separation system, can solve the problems of high environmental hazards of solvents, low recovery rate, long separation process, etc., and achieve the effect of saving separation time, saving solvent and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

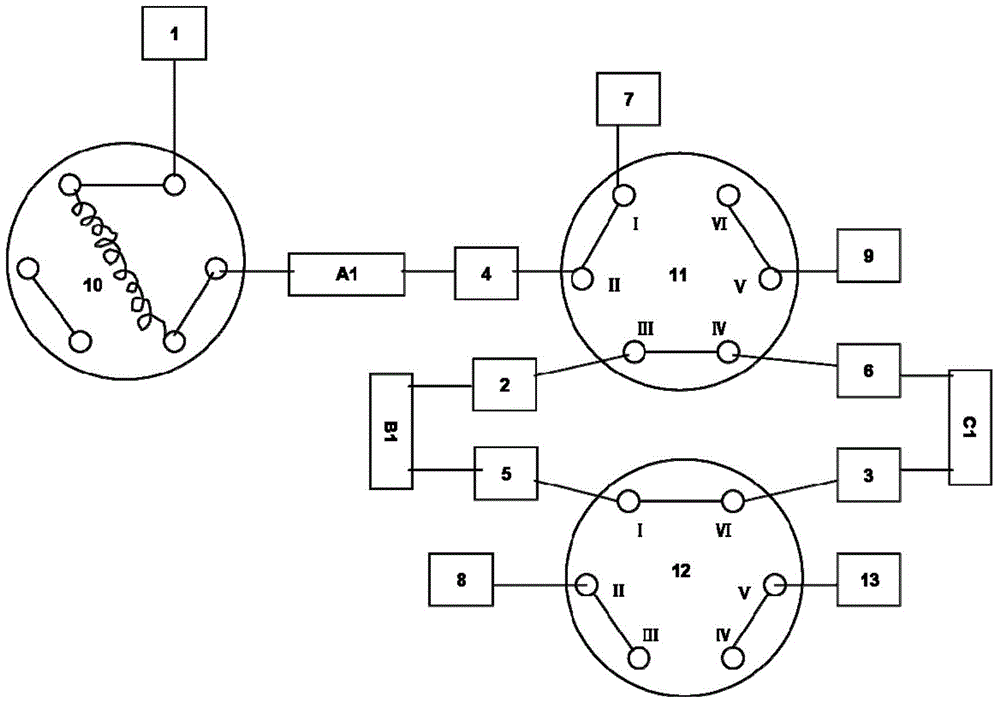

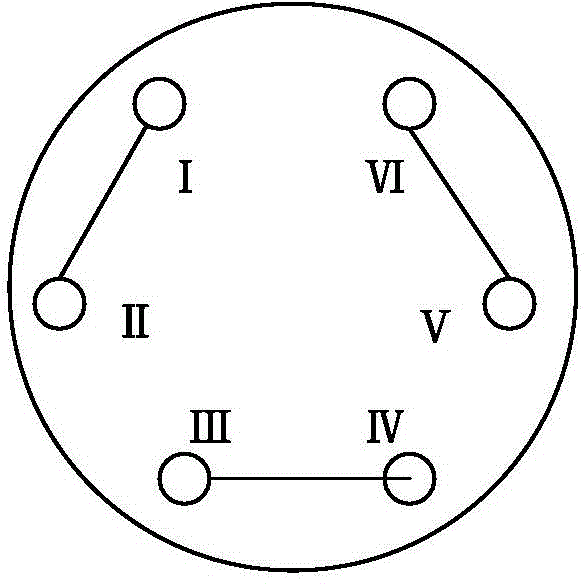

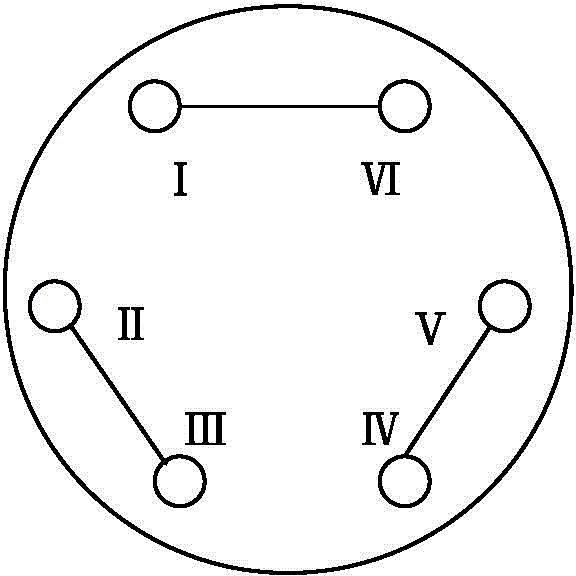

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing tanshinone compounds using a double-column circulation separation system, the tanshinone compounds comprising structural formula (1) dihydrotanshinone I, structural formula (2) trefoil B and structural formula (3) methyl tanshinone ester,

[0038]

[0039] Proceed as follows:

[0040] 1. Extraction and enrichment:

[0041] Take 9.5 kg of dry rhizome of Salvia miltiorrhiza, crush it into a 60-mesh coarse powder, place it in 30 L of ethanol with a volume concentration of 95% at room temperature and extract 3 times, each time for 24 hours, stir regularly, combine the extracts and concentrate under reduced pressure to obtain the crude extract of Salvia miltiorrhiza , take out 30g and mix the sample with normal phase silica gel, then elute with petroleum ether and ethyl acetate, collect the eluate rich in tanshinone compounds, concentrate and freeze-dry under reduced pressure, and obtain The crude product of B and methyl tanshinone ester (HPLC anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com