Spray paint organic solvent waste gas purifying device and solvent recycling method

An exhaust gas purification device and organic solvent technology, which is applied in the direction of injection devices, chemical instruments and methods, combined devices, etc., can solve the problems of affecting the purity of activated carbon, easy to adhere to activated carbon, and high dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

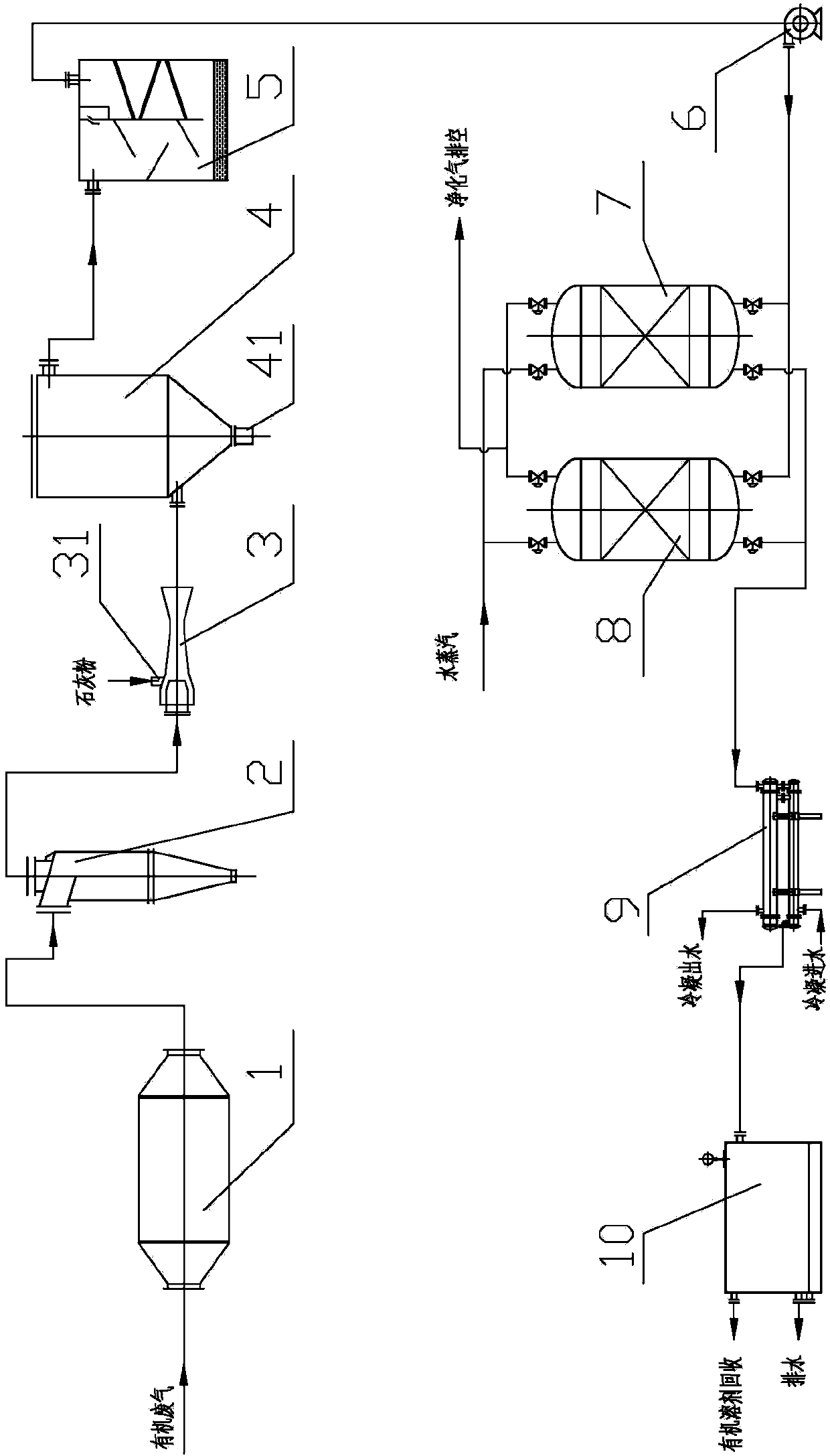

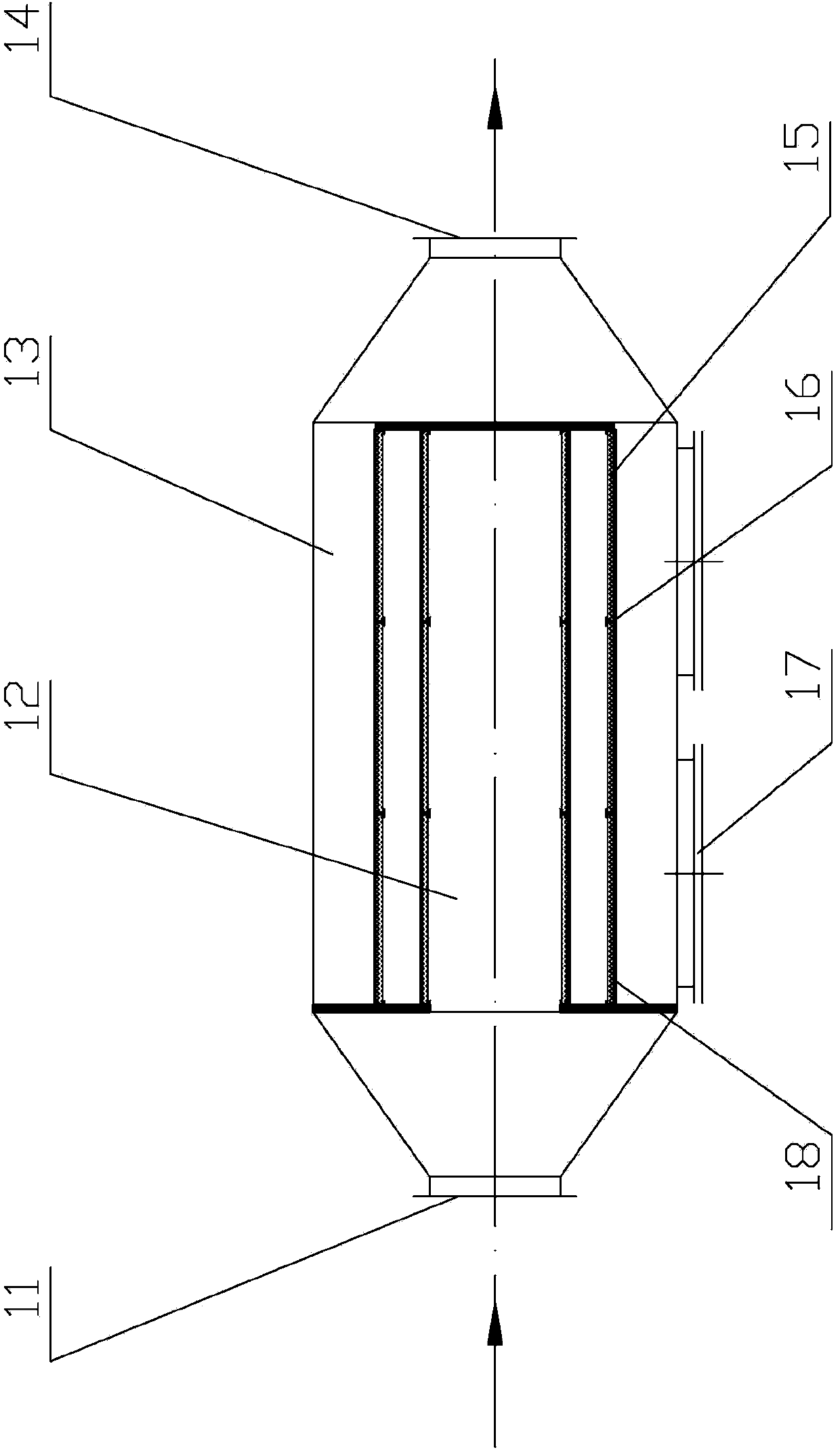

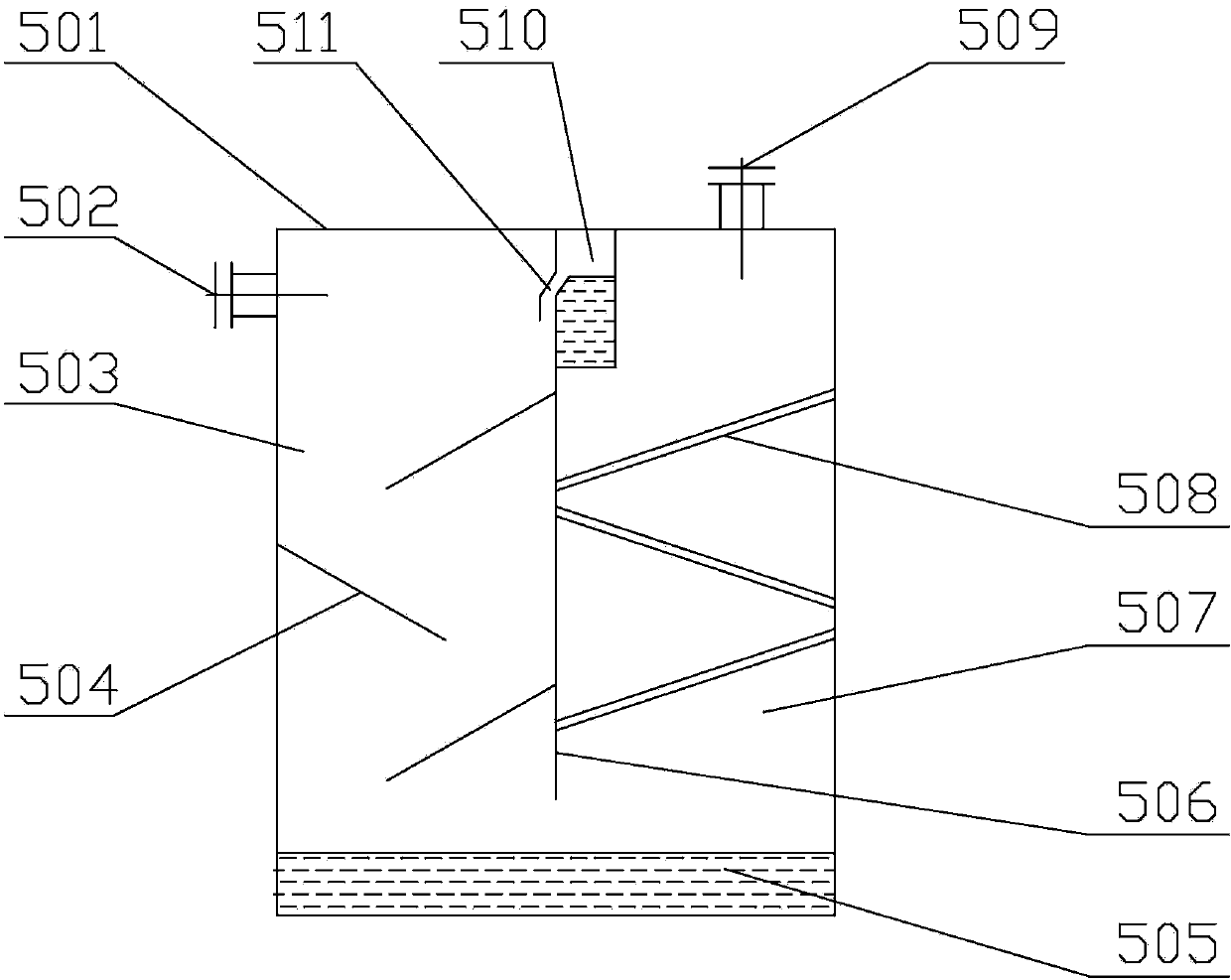

[0037] Such as figure 1 , figure 2 and image 3 As shown, a spray paint organic solvent exhaust gas purification device includes a paper filter 1, a cyclone dust collector 2, a bag dust collector 4, a high-pressure fan 6, suction (de)attachment tanks 7, 8, a condenser 9, and a specific gravity separator 10 , Venturi mixer 3 and foam deduster 5; The inlet pipe 11 of described paper filter 1 connects the organic solvent waste gas pipe from paint room, and the outlet pipe 14 of paper filter connects the inlet pipe of cyclone dust collector 2; Cyclone dust removal The outlet pipe of device 2 is connected to the inlet pipe of Venturi mixer 3, the outlet pipe of Venturi mixer 3 is connected to the inlet pipe of bag filter 4, the outlet pipe of bag filter 4 is connected to the air inlet 502 of water foam dust collector 5, and the water foam The air outlet 509 of the dust collector 5 is connected to the inlet of the high-pressure fan 6, and the outlet of the high-pressure fan 6 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap