Medicinal auxiliary material production wastewater treatment technology

A technology for the production of waste water and treatment process, applied in the direction of water/sewage multistage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problem, to achieve the effect of low operating cost, simple processing technology and strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with specific embodiments.

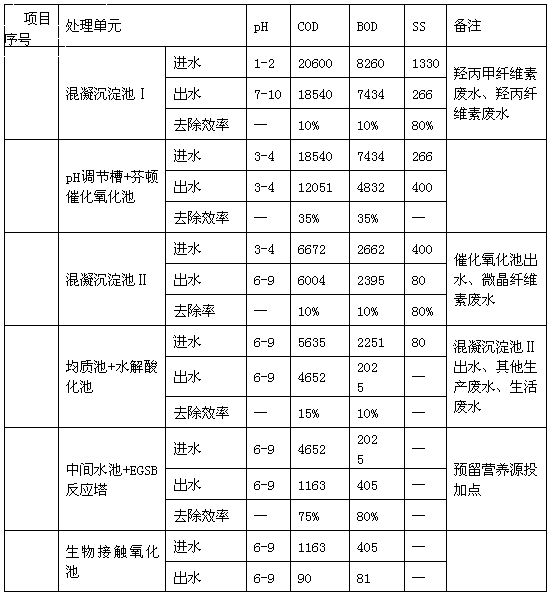

[0013] Table 1 shows the water quality indicators of wastewater discharged by a pharmaceutical excipient enterprise:

[0014] waste water type pH COD BOD NH 3 -N SS Salinity ‰ Microcrystalline Cellulose Mixed Wastewater 1-2 ≦2800 ≦1100 ≦20 ≦400 ≦3.2 Hydroxypropyl Cellulose Mixed Wastewater 1-2 ≦21000 ≦8400 ≦30 ≦1500 ≦20 Hypromellose mixed wastewater 6-9 ≦20000 ≦8000 ≦10 ≦100 ≦30 other wastewater 6-9 ≦800 ≦60 — ≦300 — Domestic wastewater 6-9 ≦350 ≦200 ≦30 ≦200 —

[0015] Treatment process of the present invention is:

[0016] The invention relates to a process for treating waste water from the production of pharmaceutical excipients. The hypromellose waste water and hypromellose waste water discharged from the production process are combined and discharged into the adjustment pool I, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com