A kind of preparation method of 1,5-dihydroxynaphthalene

A technology of dihydroxynaphthalene and refined naphthalene, which is applied in 1 field, can solve problems such as high temperature and high pressure, and achieve the effects of reducing equipment requirements, reducing emissions, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

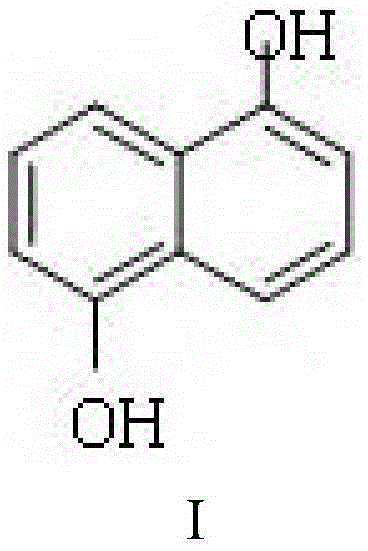

Image

Examples

preparation example Construction

[0025] The invention discloses a preparation method of 1,5-dihydroxynaphthalene, comprising the following steps:

[0026] A) After sulfonation reaction of refined naphthalene and sulfonating agent, salting out to obtain reaction solid and reaction liquid;

[0027] B) Under the action of a catalyst, the reaction solid obtained in the above step A), water and inorganic strong base are heated and reacted to obtain 1,5-dihydroxynaphthalene;

[0028] The catalyst is one or more of methanol, ethanol and propanol.

[0029] The present invention reduces the reaction temperature of the alkali fusion step in the production process of 1,5-dihydroxynaphthalene by adding a catalyst in the reaction process, thereby reducing the requirements for equipment, and also reducing the risk factor in actual production, so that the reaction conditions are mild , Easy to operate.

[0030] All the raw materials of the present invention have no special limitation on their sources, they can be purchase...

Embodiment 1

[0048] First, put 180g of 20% oleum into a 500ml three-necked bottle, and use an ice-water bath to control the temperature to 15°C. Under stirring conditions, slowly add 30.3g of refined naphthalene, complete the addition within 40 minutes, and then stir for 30 minutes Finally, raise the temperature of the above reaction system to 55°C for sulfonation reaction, after 4 hours of reaction, cool down to 30°C, slowly pour the sulfonation solution into 400g of 20% salt water for salting out, and then filter the salting out mixture , to obtain a reaction solution and a reaction solid.

[0049] The above reaction solid was dissolved in 300ml hot water, and then the pH of the solution was adjusted to 6 with sodium hydroxide, and then the temperature was lowered to 15°C for filtration to obtain a white solid, namely 1,5-naphthalene disulfonic acid. Carry out HPLC analysis to it, the result shows that the purity of 1,5-naphthalene disulfonic acid is more than or equal to 98%, it is test...

Embodiment 2

[0054] First, put 220g of sulfuric acid into a 500ml three-neck bottle, use an ice-water bath to cool and control the temperature to 18°C, and slowly add 30.3g of refined naphthalene under stirring conditions, and complete the addition within 40 minutes. After stirring for another 30 minutes, the above The temperature of the reaction system was raised to 55°C for sulfonation reaction. After 4 hours of reaction, the temperature was lowered to 30°C, and the sulfonation solution was slowly poured into 340g of 20% salt water for salting out, and then the salting out mixture was filtered through pressure to obtain a reaction liquid and react solids.

[0055] The above reaction solid was dissolved in 300ml hot water, and then the pH of the solution was adjusted to 6 with sodium hydroxide, and then the temperature was lowered to 15°C for filtration to obtain a white solid, namely 1,5-naphthalene disulfonic acid. Carry out HPLC analysis to it, the result shows that the purity of 1,5-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com