Thermoplastic polyimide and method for preparing flexible copper-clad plate from thermoplastic polyimide

A polyimide and polyimide film technology, applied in the field of thermoplastic polyimide, can solve the problems of low production efficiency and product yield, complicated operation, etc., achieve high peel strength, simple operation, and improve production efficiency and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

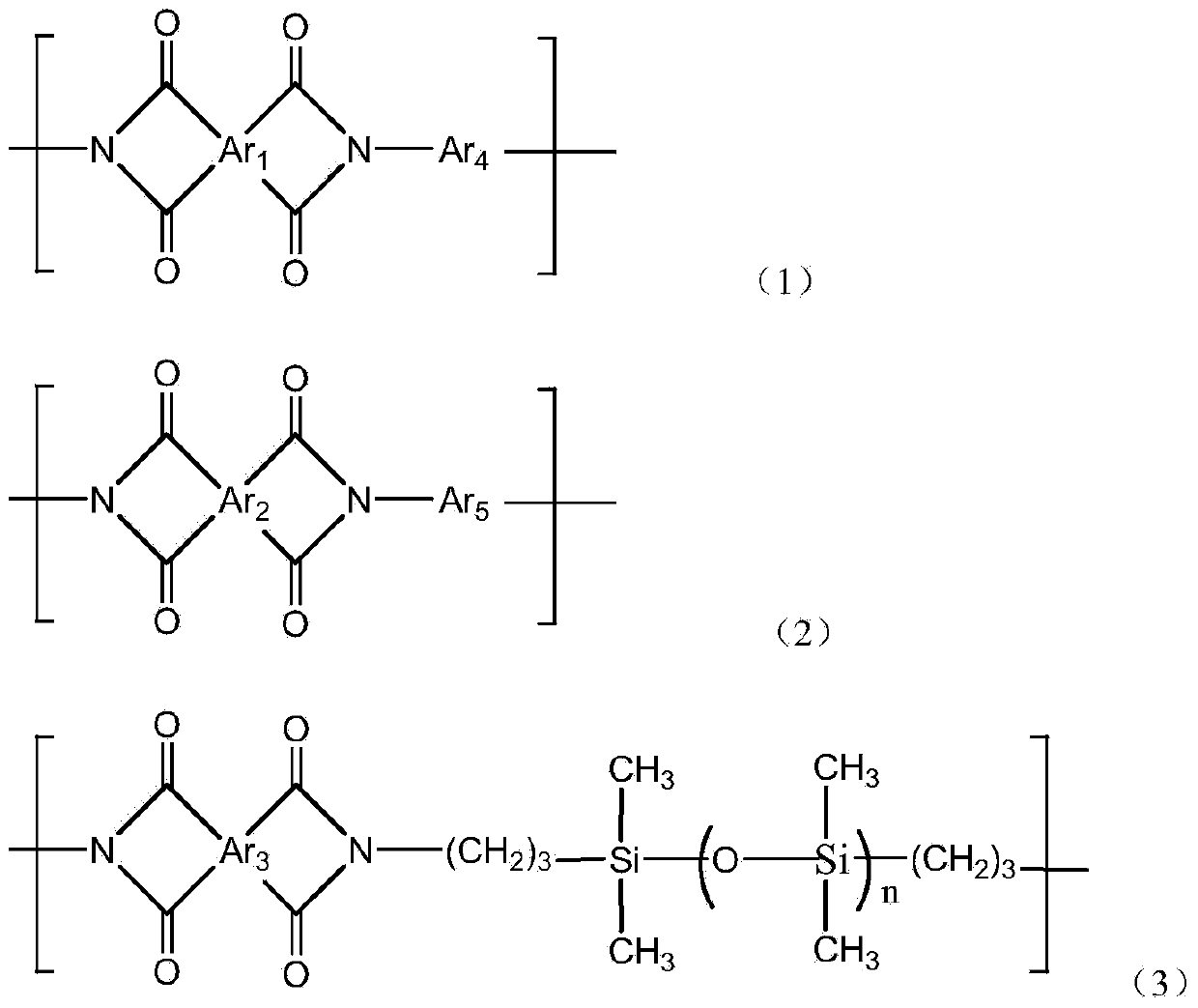

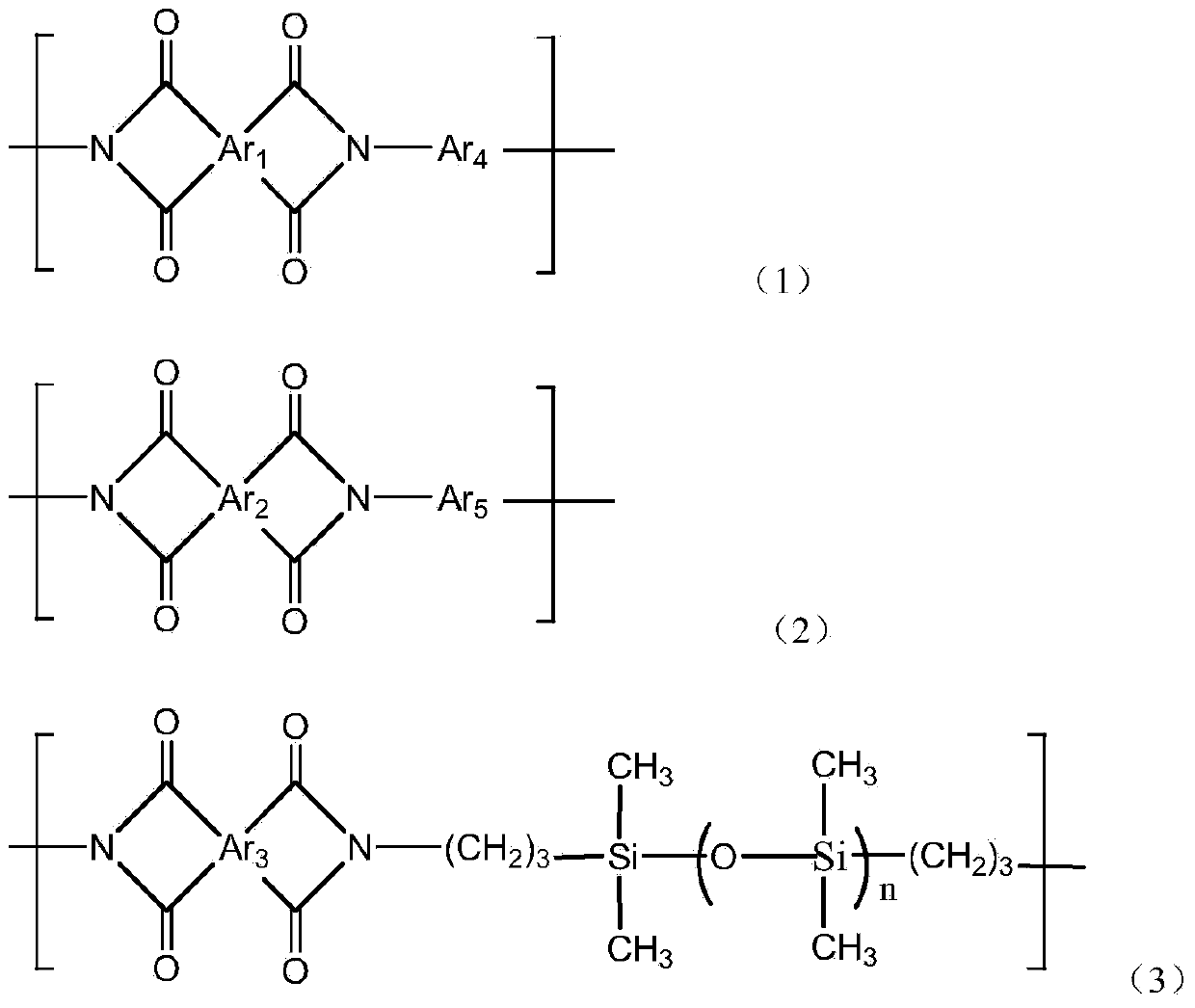

[0043] In a 500ml four-neck flask equipped with a stirring device, add 10.08g of 2-(4-aminophenyl)-5-aminobenzimidazole, 4.96g of 1,3-bis(3-aminopropyl) Tetramethyldisiloxane, 4.1g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane, 5g of 4,4'-diaminodiphenyl ether, 220ml of dimethyl Acetamide, while stirring nitrogen gas, after the above-mentioned diamine monomer is completely dissolved, add 18.6g of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride at room temperature, stir for 1 hour and then add 12.05 g of 3,3',4,4'-biphenyltetracarboxylic dianhydride was stirred continuously for 5 hours and then stopped to obtain a polyamic acid solution, that is, a thermoplastic polyimide precursor solution.

Synthetic example 2

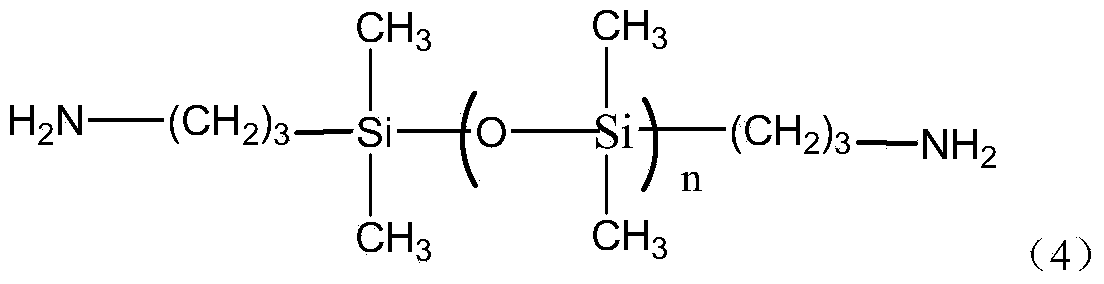

[0045] In a 500ml four-neck flask equipped with a stirring device, add 11.25g of 2-(4-aminophenyl)-5-aminobenzoxazole, 8.16g of 1,11-bis(3-aminopropyl ) dodecamethylpolysiloxane, 4.1g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane, 5g of 4,4'-diaminodiphenyl ether, 220ml of diaminodiphenyl ether Methyl acetamide, while stirring nitrogen gas, after the above-mentioned diamine monomer is completely dissolved, add 18.6g of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride at room temperature, and stir for 1h Then add 12.05g of 3,3',4,4'-biphenyltetracarboxylic dianhydride, continue to stir and react for 5h, add 3.16g of pyridine and 8.16g of acetic anhydride and stop stirring for 30min to obtain a polyamic acid solution. That is, the precursor solution of thermoplastic polyimide.

Synthetic example 3

[0047] In a 500ml four-necked flask equipped with a stirring device, sequentially add 12g of 4,4'-diaminodiphenyl ether, 4.32g of p-phenylenediamine, and 160ml of dimethylacetamide, and pass nitrogen gas while stirring , after the above-mentioned diamine monomer is completely dissolved, add 17.44g of pyromellitic dianhydride at room temperature, stir for 1 hour and then add 6.17g of 3,3',4,4'-biphenyltetracarboxylic dianhydride, The reaction was stopped after continuous stirring for 5 hours to obtain a polyamic acid solution, that is, a precursor solution of a thermosetting polyimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com