Phosphorus-nitrogen flame retardant and preparation method thereof

A flame retardant, phosphorus and nitrogen technology, applied in the field of flame retardant, can solve problems such as hazards, threats to life and property safety, etc., and achieve the effect of high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

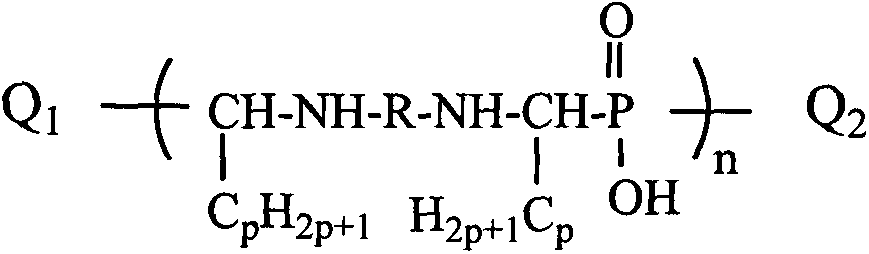

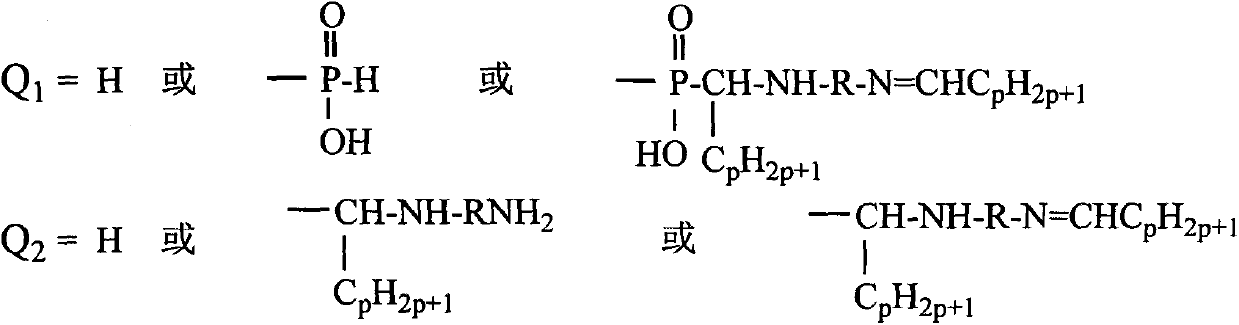

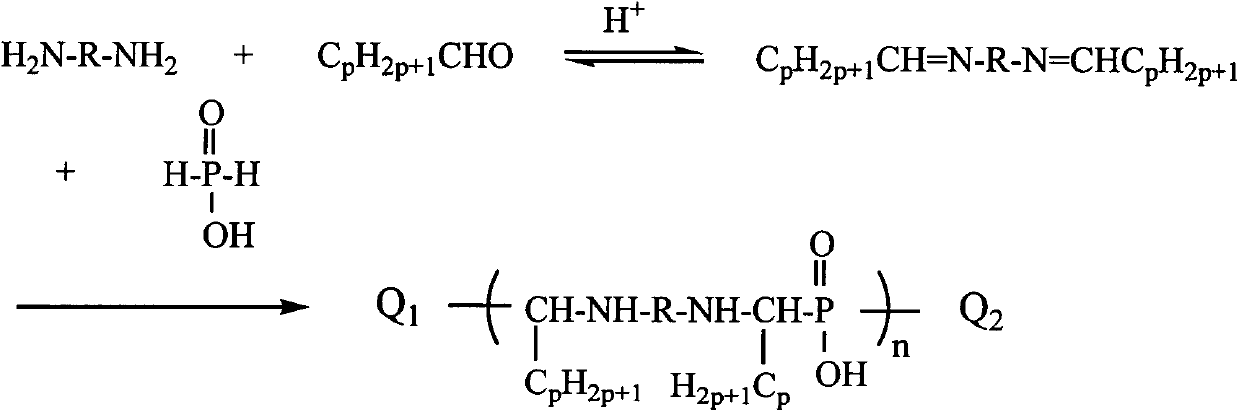

Image

Examples

preparation example Construction

[0016] The preparation method of the phosphorus-nitrogen type flame retardant of the present invention is: using organic amine, hypophosphorous acid and fatty aldehyde as raw materials to react and synthesize the phosphorus-nitrogen type flame retardant containing two elements of phosphorus and nitrogen under acid catalysis; wherein, the organic amine is the molecular formula NH 2 RNH 2 One or more than one dibasic primary amines, R can be -(CH 2 ) m -, -[CH 2 CH 2 NH] p CH 2 CH 2 -or-C 6 h 4 -, m and p are all positive integers and 6≥m≥2, 4≥p≥1; fatty aldehyde is one or more of formaldehyde, acetaldehyde, propionaldehyde or butyraldehyde.

[0017] The organic amine of the present invention can be that molecular formula is NH 2 RNH 2 A dibasic primary amine, which can also be a molecular formula of NH 2 RNH 2 A mixed dibasic primary amine of two or more dibasic primary amines. NH 2 RNH 2 It may be ethylenediamine, propylenediamine, butylenediamine, pentamethyle...

Embodiment 1

[0023] Example 1 Add the raw material ethylenediamine, hypophosphorous acid and formaldehyde solution (30% concentration) with a molar ratio of ethylenediamine, hypophosphorous acid and formaldehyde of 1:3:3 into the reaction kettle, and add hydrochloric acid solution (the hydrochloric acid in the system provides H + The concentration is 0.004mol / L), after stirring evenly, the temperature rises to 75°C and reacts for 4 hours. After the reaction is completed, it is filtered, and the filter cake is washed with acetone, dichloromethane and deionized water successively, and dried in vacuum to obtain a dark yellow solid, namely It is the phosphorus nitrogen type flame retardant of the present invention. When it is used in flame-retardant epoxy resin, the phosphorus-nitrogen type flame retardant synthesized here alone can make the horizontal combustion level reach FH-1 level when the dosage is 18%.

Embodiment 2

[0024] Example 2 Add diethylenetriamine, hypophosphorous acid and formaldehyde solution (30% concentration) of diethylenetriamine, hypophosphorous acid and formaldehyde in a molar ratio of 1:3:4 to the reaction kettle, and add hydrochloric acid-sulfuric acid mixed solution (the 36% concentrated hydrochloric acid of hydrochloric acid-sulfuric acid mixed solution: 98% concentrated sulfuric acid is 5: 1 (mass ratio), the H that hydrochloric acid-sulfuric acid mixed solution provides in the system + The concentration is 0.006mol / L), after stirring evenly, the temperature rises to 85°C and reacts for 3 hours. After the reaction is completed, it is filtered, and the filter cake is washed with acetone, dichloromethane and deionized water successively, and dried in vacuum to obtain a dark yellow solid, namely It is the phosphorus nitrogen type flame retardant of the present invention. It is used for flame-retardant epoxy resin, and when the phosphorus-nitrogen type flame retardant syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com